Soced Weld Cyplu Llawn

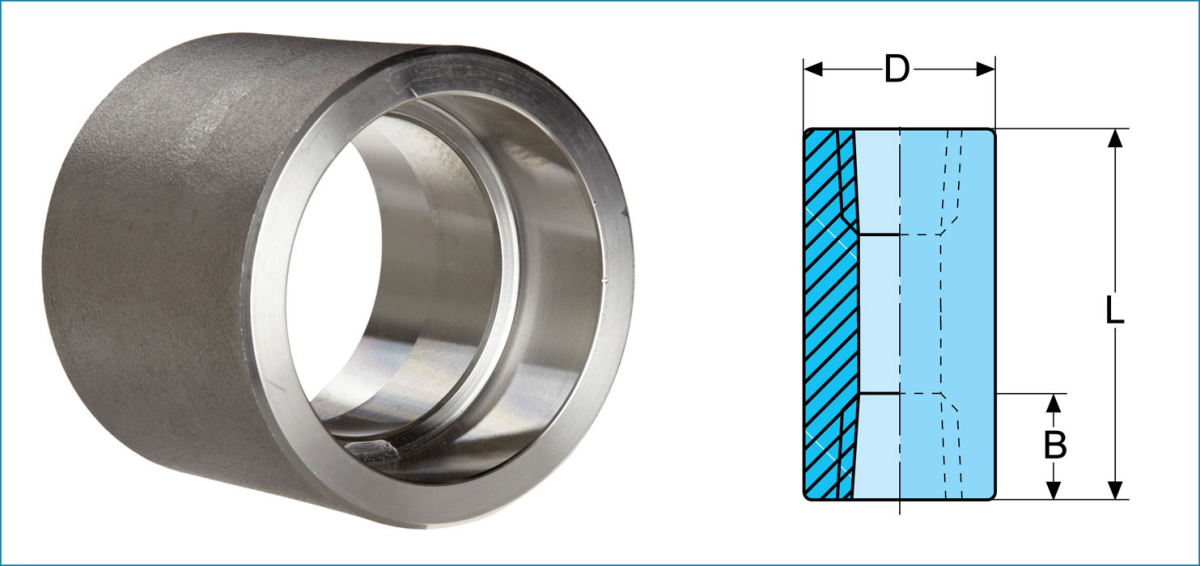

Fel cwmni ardystiedig ISO, mae Liaocheng Shenghao Metal products Co, LTD wedi gwneud ei ffordd i mewn i'r marchnadoedd cenedlaethol a rhyngwladol fel un o brif ddosbarthwyr, cyflenwr a stociwr Socket Weld Full Coupling. Defnyddir Socket Weld Couplings Llawn i gysylltu turio bachpibellau fel rhagamcan o effaith weldio ar y turio pibell. Mae dau ben y Cyplyddion Llawn hyn wedi'u edafeddu. Mae galw mawr amdanynt yn y farchnad gosod pibellau. Mae'r Cyplyddion Hanner Weld Soced Dur Di-staen hyn yn cael eu profi'n drylwyr i sicrhau'r ansawdd uchaf adygnwch o dan unrhyw amodau eithafol. Mae'r Cyplyddion Llawn Soced Weld ffug ANSI B16.11 hyn yn cael eu defnyddio mewn cymwysiadau megis fferyllol, adeiladu llongau, ac ati. Mae HGFF Group Co, Ltd yn gyfrifol am eucwsmeriaid yr ASME B16.11 Forged Socket Weld Couplings Llawn am brisiau rhesymol. Fe'u darperir mewn gwahanol feintiau a thrwch ar gyfer anghenion penodol y cwsmeriaid.

ANSI/ASME B16.11 Manyleb Safonol Cyplu Llawn Soced Weld

Soced Weld Cyplu Maint Llawn

| Dimensiynau | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Maint | 1/8″ DS I 4″ DS |

| Graddfeydd Pwysau | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Ffurf | Cyplyddion Llawn, Lleihau Cyplu |

| Graddau Cynhyrchu | Dur Di-staen, Dur Alloy, Duplex, Aloeon Nicel, Dur Tymheredd Isel, Dur Carbon, Cupro Nicel |

Safonau Gweithgynhyrchu Cyplu Llawn Weld Soced

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Forged Socket Weld Graddau Deunydd Cyplu Llawn

Cyplu Llawn Weld Soced Wedi'i Ffugio Nicel Alloy :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400 ) 20, UNS 400 200 , UNS 400 , UNS 4400 (MONEL 400 ) 20, 2000, 200, 200, 200, 200, 200, 200, 200, 200, 200, 200, 200, 2000, UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ), UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Cyplu Llawn Weld Soced Forged Dur Di-staen:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F323, FH, F 454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Soced Gofannu Dur Weld Cyplydd Llawn :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Cyplydd Llawn Weld Soced Dur Carbon:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Cyplydd Llawn Weld Soced Dur Alloy :

ASTM/ASME A 182, ASTM/ASME A 335, ASTM/ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM/ASME A 691 GR 1 CR , 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Soced Weld Cyplu Llawn: ASTM / ASME SB 111 UNS RHIF. C 10100 , C 10200 , C 10300 , C 10800 , C 12000 , C 12200 , C 70600 C 71500 , ASTM / ASME SB 466 UNS RHIF. C 70600 ( CU - NI- 45/10 ), C 71500 ( CU -NI- 70/30)

ASME B16.11 Forged Socket Weld Cyplu Llawn Mathau sydd ar Gael

| Gofannu Soced weldiad Cyplydd Llawn | Soced Weld Dosbarth Cyplu Llawn 3000 |

| Soced Weld Lleihau Cyplu | 3 4 Soced Weld Cyplu Llawn |

| ASME B16.11 Soced Weld Lleihau Coupling | 3000LB Soced Weld Cyplu Llawn |

| ANSI B16.11 Cyplu Llawn Weld Soced Forged | Cyplu Llawn Weld Soced Dosbarth 6000 |

| Soced Weld Cyplu Llawn Pwysau | BS 3799 Coupling Llawn Weld Soced Forged |

| Gostyngwyr Cyplu Llawn Socket Weld | Ansawdd Uchel Soced weldiad Cyplydd Llawn |

| 2 Soced Weld Cyplu Llawn | 1/2 Soced Weld Cyplydd Llawn |

| 3000# Cyplu Llawn Weld Soced Forged | 3/4 Soced Weld Cyplu Llawn |

| 5 Soced Weld Cyplu Llawn | 1 fodfedd Soced Weld Cyplu Llawn |

| 8 Soced Weld Cyplu Llawn | Cyplu Llawn Weld Soced 2 fodfedd |

| 6000# Soced Weld Cyplu Llawn | 3 modfedd Soced Weld Cyplu Llawn |

| 6 Soced Weld Cyplu Llawn | 6 modfedd Soced Weld Cyplu Llawn |

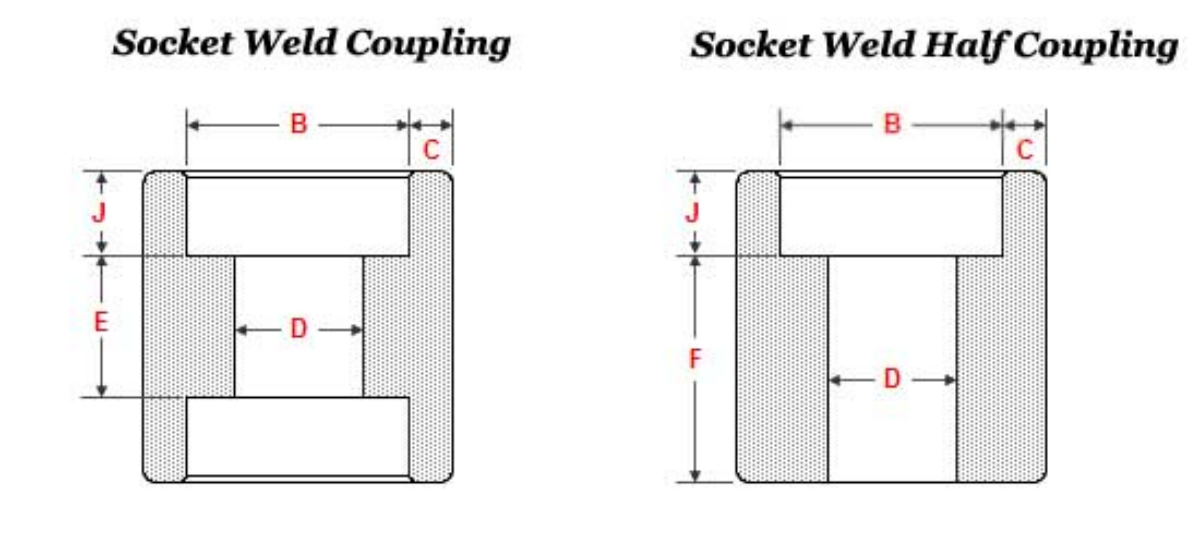

ANSI/ASME B16.11 DIMENSIYNAU CYSYLLTU LLAWN WELD soced

Socket Weld Lleihau Dimensiynau Cyplu

3000# Dimensiynau Cyplu Weld Soced

| NPS | Soced Bore | Dyfnder Soced | Bore DIA | Soced wal THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 | 4.65 4.10 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 | 4.90 4.25 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 | 5.70 5.00 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 | 6.05 5.30 |

| 1.1/2 | 48.90 48.65 | 13 | 41.7 40.1 | 6.35 5.55 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 | 6.95 6.05 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 | 8.75 7.65 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 | 9.50 8.30 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 | 10.70 9.35 |

| NPS | Gosod hyd | |||

| Cyplu E | Cyplu hanner F | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 | 47.5 | ||

Dimensiynau Cyplu Weld Soced 6000#

| NPS | Soced | Dyfnder | Bore | Soced |

| B | J | D | C | |

| 1/2 | 21.95 | 10 | 12.5 | 5.95 |

| 3/4 | 27.30 | 13 | 16.3 | 6.95 |

| 1 | 34.05 | 13 | 21.5 | 7.90 |

| 1.1/4 | 42.80 | 13 | 30.2 | 7.90 |

| 1.1/2 | 48.90 | 13 | 34.7 | 8.90 |

| 2 | 61.35 | 16 | 43.6 | 10.90 |

| NPS | Gosod hyd | |||

| Cyplu | Cyplu hanner | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

Mae dimensiynau mewn milimetrau oni nodir yn wahanol.

Bore Soced (B) – Dimensiynau mwyaf a lleiaf.

Diamedr Tyllu (D) – Dimensiynau mwyaf a lleiaf.

Trwch wal soced - (C) - Trwch wal soced ar gyfartaledd.

Canolbwynt goddefiannau dimensiwn i waelod y soced - (A)

NPS 1/2 a NPS 3/4 = +/- 1.5 mm

NPS 1 i NPS 2 = +/- 2 mm

NPS 2.1/2 i NPS 4 = +/- 2.5 mm