Socket Weld Folsleine Koepeling

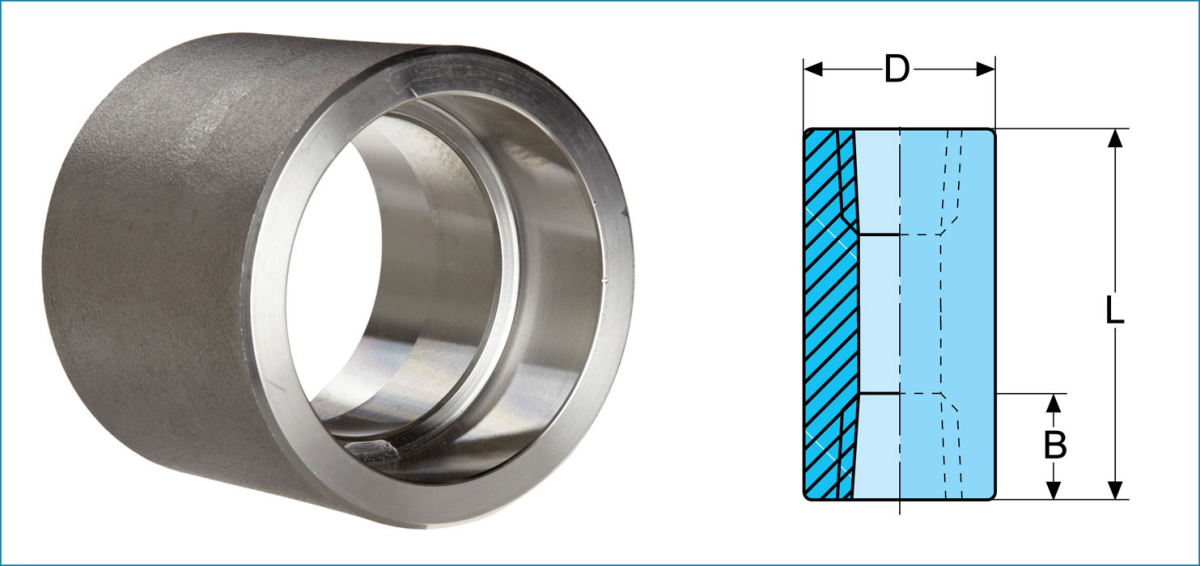

As ISO-sertifisearre bedriuw hat Liaocheng Shenghao Metal products Co., LTD syn wei fûn nei de nasjonale en ynternasjonale merken as ien fan 'e liedende distributeurs, leveransiers en stockisten fan Socket Weld Full Coupling. Socket Weld Full Couplings wurde brûkt om lytse diameters te ferbinen.pipen as in projeksje fan in laseffekt op 'e piipboring. Beide úteinen fan dizze folsleine koppelingen binne skroefd. Se binne tige frege yn 'e merk foar piipfittingen. Dizze roestfrij stielen mofetlas-healkoppelingen wurde strang hifke om de heechste kwaliteit te garandearjen enúthâldingsfermogen ûnder alle ekstreme omstannichheden. Dizze ANSI B16.11 smeide socket-weld folsleine koppelingen wurde brûkt yn tapassingen lykas farmaseutika, skipsbou, ensfh. HGFF Group Co., Ltd. draacht by oan harkliïnten de ASME B16.11 smeide socket weld folsleine koppelingen tsjin ridlike prizen. Se wurde levere yn ferskate maten en dikte foar de spesifike behoeften fan 'e klanten.

ANSI/ASME B16.11 Socket Weld Folsleine Koepel Standert Spesifikaasje

Socket Weld Folsleine Koppelingsgrutte

| Ofmjittings | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Grutte | 1/8″ NB oant 4″ NB |

| Drukbeoardielingen | 2000 pûn, 3000 pûn, 6000 pûn, 9000 pûn |

| Foarm | Folsleine koppelingen, ferminderingskoppeling |

| Produksjegraden | RVS, Legeringstiel, Duplex, Nikkellegeringen, Leechtemperatuerstiel, Koalstofstiel, Cupronikkel |

Produksjenormen fan Socket Weld Folsleine Koppeling

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Smeid Socket Weld Folsleine Koepelmateriaal Graden

Nikkellegering smeide socket weld folsleine koppeling:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NIKKEL 200), UNS 2201 (NIKKEL 201) , UNS 4400 (MONEL 400 ) 02 (AL 400 ) 02 ), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

RVS smeide socket weld folsleine koppeling:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Stiel Smeid Socket Weld Folsleine Koppeling:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Koalstofstiel smeide socket weld folsleine koppeling:

ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Smeidde socket weld folsleine koppeling fan legearing stiel:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Koperlegering stiel smeide mofet las folsleine koppeling: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 45/10), C 71500 (CU -NI- 70/30)

ASME B16.11 Smeid Socket Weld Folsleine Koepeling Beskikbere Typen

| Smeid Socket weld Folsleine Koppeling | Socket Weld Folsleine Koppeling Klasse 3000 |

| Socket Weld Reduksjekoppeling | 3 4 Socket Weld Folsleine Koppeling |

| ASME B16.11 Socket Weld Reduzearjende Koppeling | 3000LB Socket Weld Folsleine Koppeling |

| ANSI B16.11 Smeid Socket Weld Folsleine Koepeling | Klasse 6000 Socket Weld Folsleine Koppeling |

| Gewicht fan folsleine koppeling foar socketweld | BS 3799 Smeid Socket Weld Folsleine Koppeling |

| Socket Weld Folsleine Koppelingsreduksjes | Hege kwaliteit Socket weld Folsleine koppeling |

| 2 Socket Weld Folsleine Koppeling | 1/2 Socket Weld Folsleine Koppeling |

| 3000 # Smeide Socket Weld Folsleine Koppeling | 3/4 Socket Weld Folsleine Koppeling |

| 5 Socket Weld Folsleine Koppeling | 1 inch Socket Weld Folsleine Koppeling |

| 8 Socket Weld Folsleine Koppeling | 2 inch Socket Weld Folsleine Koppeling |

| 6000# Socket Weld Folsleine Koppeling | 3 inch Socket Weld Folsleine Koppeling |

| 6 Socket Weld Folsleine Koppeling | 6 inch Socket Weld Folsleine Koppeling |

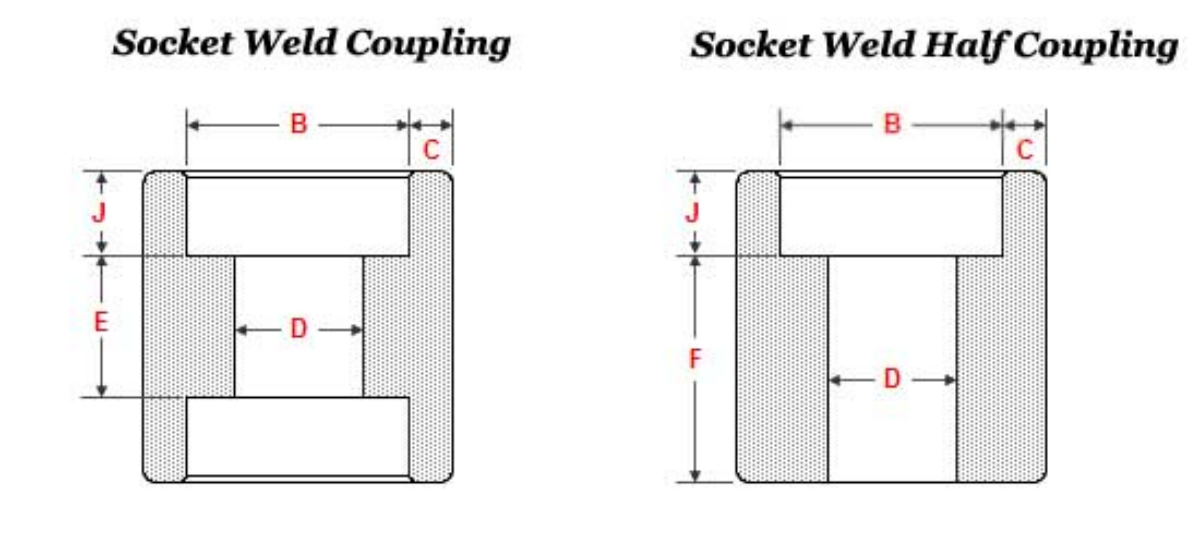

ANSI/ASME B16.11 SOCKET WELD FOLLE KOPPELING AFMETINGEN

Ofmjittings fan 'e socket weld reducing coupling

3000# Ofmjittings fan 'e mofetlaskoppeling

| NPS | Stopkontakt Boarring | Djipte Stopkontakt | Boarring DIA | Stopkontakt muorre THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 | 4.65 4.10 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 | 4.90 4.25 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 | 5.70 5.00 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 | 6.05 5.30 |

| 1.1/2 | 48.90 48.65 | 13 | 41.7 40.1 | 6.35 5.55 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 | 6,95 6.05 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 | 8.75 7.65 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 | 9.50 8.30 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 | 10.70 9.35 |

| NPS | Lizzende lingten | |||

| Koppeling E | Healkoppeling F | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 | 47.5 | ||

6000# Ofmjittings fan 'e mofetlaskoppeling

| NPS | Stopkontakt | Djipte | Boarring | Stopkontakt |

| B | J | D | C | |

| 1/2 | 21.95 | 10 | 12.5 | 5.95 |

| 3/4 | 27.30 | 13 | 16.3 | 6,95 |

| 1 | 34.05 | 13 | 21.5 | 7.90 |

| 1.1/4 | 42.80 | 13 | 30.2 | 7.90 |

| 1.1/2 | 48.90 | 13 | 34.7 | 8.90 |

| 2 | 61.35 | 16 | 43.6 | 10.90 |

| NPS | Lizzende lingten | |||

| Koppeling | Healkoppeling | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

Ofmjittings binne yn millimeters, útsein as oars oanjûn.

Mofboring (B) - Maksimale en minimale ôfmjittings.

Boardiameter (D) - Maksimale en minimale ôfmjittings.

Dikte fan 'e socketwand – (C) – Gemiddelde fan 'e dikte fan 'e socketwand.

Dimensjonele tolerânsjes sintraal nei de ûnderkant fan 'e socket - (A)

NPS 1/2 en NPS 3/4 = +/- 1,5 mm

NPS 1 oant NPS 2 = +/- 2 mm

NPS 2.1/2 oant NPS 4 = +/- 2.5 mm