Socket Lasuny

As liedende eksporteur, distributeur en leveransier fan Socket Weld Union Fittings, hat Liaocheng Shenghao Metal products Co., LTD. konsekwint ynspanningen dien om in breed oanbod fan produkten oan har klanten te leverjen. It is in ISO-sertifisearre bedriuw dat garandearret dat har kliïnten produkten fan hege kwaliteit krije.produkten. RVS-socket-lasunions wurde brûkt yn leechdrukpipen wêr't it nedich is om de piip faak te demontearjen. In smeide socket-lasunion is in skroefferbiningûntwerp. It bestiet út trije ûnderling ferbûne stikken. Dizze fitting hat twa ynterne triedden en in sintrumstik dat de einen byinoar lûkt as se draaid wurde. OmOm de kromming fan 'e sitten te minimalisearjen, moatte de ferbiningen goed fêstskroefd wurde foardat it ein lassen wurdt. ANSI B16.11 Socket LasunionFittings binne beskikber yn oanpasbere maten neffens de fersyk fan 'e klant. HGFF Group Co., Ltd produseart feilloos SocketLasunions om har kliïnten ultime gemak te bieden.

ANSI/ASME B16.11 Socket Lasunion Standert Spesifikaasje

| Ofmjittings | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Grutte | 1/8″ NB oant 4″ NB |

| Drukbeoardielingen | 2000 pûn, 3000 pûn, 6000 pûn, 9000 pûn |

| Foarm | Socket Weld Union, Socket Weld Pipe Union, Socket Weld Orifice Union, Smeed Union, Socket Weld Union Fittings |

| Produksjegraden | RVS, legearingstiel, duplex, nikkellegeringen, leechtemperatuerstiel, koalstofstiel, kopernikkel |

Produksjenormen fan Socket Weld Union Fittings

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Smeid Socket Weld Union Materiaal Graden

Nikkellegering smeide socket welduny:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NIKKEL 200), UNS 2201 (NIKKEL 201) , UNS 4400 (MONEL 400 ) 02 (AL 400 ) 02 ), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

RVS smeide socket weldunion:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Stiel Smeid Socket Lasunion:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Smeidde koalstofstiel Socket Weld Union:

ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Smeidde socket lasferbining fan legearing stiel:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Smeide mofetlasferbining fan koperlegering stiel: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 45/10), C 71500 (CU -NI- 70/30)

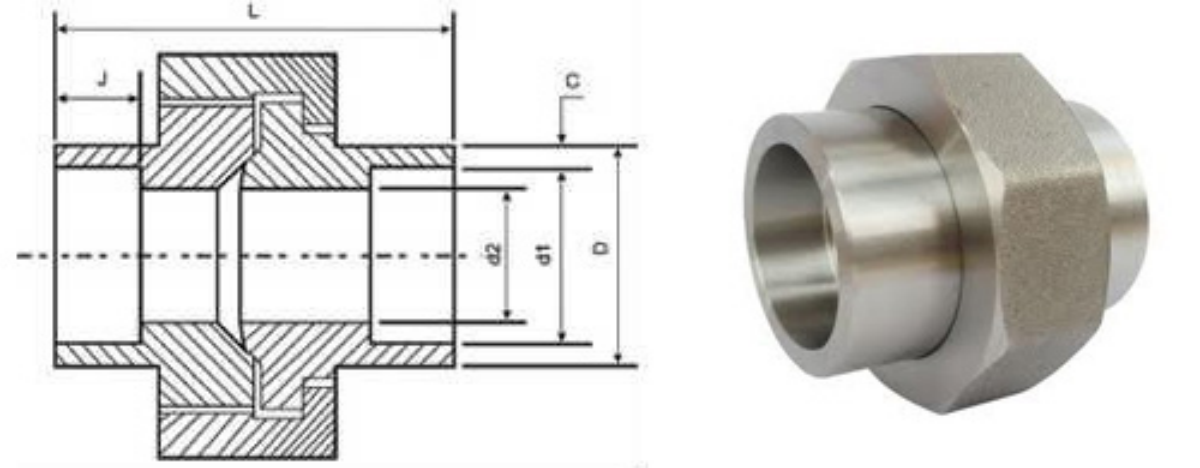

ANSI/ASME B16.11 SOCKET WELD UNION AFMETINGEN

Ofmjittings fan 'e socket weld piipunksje

| Nominale diameter | Bûtenste diameter | Muurdikte | Socketboring | Wetterwei Boar | Djipte fan 'e socket | Lingte Gearstalling | |||

| Dmin | Cmin | d1 | d2 | Jmin | L | ||||

| DN | NPS | Stopkontakt | Triedde | Stopkontakt | Triedde | Stopkontakt | Socket & Threaded | Stopkontakt | Socket & Threaded |

| 6 | 1/8 | 21.8 | 14.7 | 3.2 | 2.5 | 10.65 | 6.43 | 10 | 41.4 |

| 8 | 1/4 | 21.8 | 19.0 | 3.3 | 3.1 | 14.10 | 9.45 | 10 | 41.4 |

| 10 | 3/8 | 25.9 | 22.9 | 3.5 | 3.2 | 17.55 | 13.51 | 10 | 46.0 |

| 15 | 1/2 | 31.2 | 27.7 | 4.1 | 3.8 | 21.70 | 17.07 | 10 | 49.0 |

| 20 | 3/4 | 37.1 | 33.5 | 4.3 | 4.0 | 27.05 | 21.39 | 13 | 56.9 |

| 25 | 1 | 45.5 | 41.4 | 5.0 | 4.6 | 33.80 | 27.74 | 13 | 62.0 |

| 32 | 11/4 | 54.9 | 50.5 | 5.3 | 4.9 | 42.55 | 35.36 | 13 | 71.1 |

| 40 | 11/2 | 61.5 | 57.2 | 5.6 | 5.1 | 48.65 | 41.20 | 13 | 76.5 |

| 50 | 2 | 75.2 | 70.1 | 6.1 | 5.6 | 61.10 | 52.12 | 16 | 86.1 |

| 65 | 21/2 | 91.7 | 85.3 | 7.7 | 7.1 | 73.80 | 64.31 | 16 | 102.4 |

| 80 | 3 | 109.2 | 102.4 | 8.4 | 7.7 | 89.80 | 77.27 | 16 | 109.0 |

Gewicht fan mofetlasuny 2 Mofetlasuny

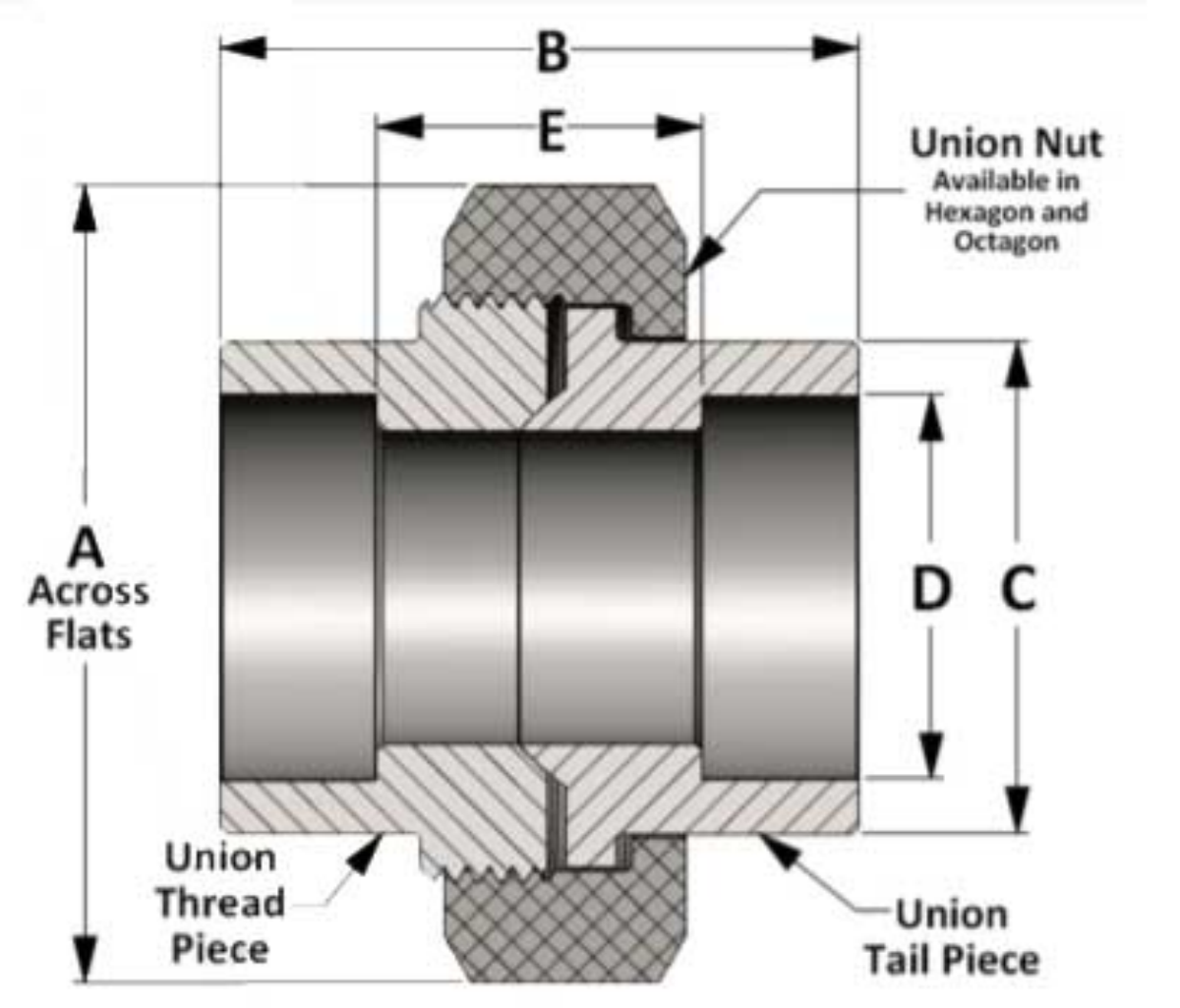

| KLASSE 3000 Socket Lasunion | ||||||||||||

| PIPGRUTTE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 |

| B | 1.688 | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 |

| C | 0.865 | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | 4.545 |

| E | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 2.313 | 5.000 |

| LBS | 0.40 | 0.38 | 0.52 | 0.73 | 1.19 | 1.66 | 2.66 | 3.42 | 5.36 | 9.12 | 12.58 | 17.50 |

| KLASSE 6000 Socket Lasunion | ||||||||||||

| PIPGRUTTE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 | — |

| B | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 | — |

| C | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 | — |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | — |

| E | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 5.750 | — |

| LBS | 0.48 | 0.56 | 0.75 | 1.35 | 2.01 | 3.17 | 3.92 | 6.60 | 10.12 | 14.00 oere | 40.891 | — |

| KLASSE 9000 Socket Lasunion | ||||||||||||

| PIPGRUTTE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.750 | 2.000 | 2.250 | 2.563 | 3.063 | 3.688 | 4.313 | 5.000 | 5.750 | 6.875 | — | — |

| B | 2.500 | 2.563 | 2.938 | 3.250 | 3.750 | 4.000 | 4.625 | 4.813 | 5.563 | 6.25 | — | — |

| C | 1.000 | 1.250 | 1.500 | 1.750 | 2.250 | 2.500 | 3.000 | 3.625 | 4.250 | 5.000 | — | — |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | — | — |

| E | 1.720 | 1.688 | 1.938 | 2.000 | 2.375 | 2.375 | 3.000 | 2.938 | 3.188 | 3.750 | — | — |

| LBS | 0.89 | 1.045 | 1.955 | 3.29 | 5.34 | 7.99 | 12.73 | 18.34 | 26.36 | 37.07 | — | |

Applikaasje fan smeide socket weld piipkap

ASME B16.11 Socket weld Pipe Cap binne bekend om útsûnderlike prestaasjes te leverjen en wurde oer it algemien ûntwikkele

om oan de easken te foldwaan. Wy biede in breed oanbod fan smeide socket-laspiipkappen fia in wrâldwiid netwurk.

fan foarriedhâldende tûken. Dizze smeide mofetlaske piipkap wurdt brûkt yn ferskateyndustryen lykas:

RVS smeide socket weld piipkap brûkt yn oalje- en gaspipeline

Gesmede Socket Weld Pipe Cap brûkt yn 'e gemyske yndustry

Gebrûk fan legearingstielsocket-weldpiipkap yn loodgieterswurk

Smeid Socket weld End Pipe Caps brûkt yn ferwaarming

Socket weld Forged Pipe Caps brûkt yn wetterfoarsjenningssystemen

ANSI B16.11 Smeid Socket Weld Pipe Cap brûkt yn Power Plant

Gebrûk fan socket-laspiipkappen yn 'e papier- en pulpyndustry

Gebrûk fan smeide socket-laspiipkappen yn algemiene tapassingen

Gebrûk fan smeide socket-weldpipe cap yn 'e fabrikaazjesektor

Gesmede Socket Weld Pipe Cap brûkt yn 'e Food Processing Industry

Gebrûk fan smeide socket-weldpiipkappen yn strukturele piip