Skroefde T-stuk / T-stuk mei skroefdraad

Liaocheng Shenghao Metal products Co., LTD is in tige priizge fabrikant fan ASME B16.11 Threaded T-stukken, dy't tige resistint is tsjin gemyske korrosje en oksidaasje (korrosjebestindich), en hat in hege spanning-brek-effektiviteit en lege kruipsnelheden ûnder hege spanningen by temperatueren nei geskikte waarmtebehanneling. Threaded Equal T-stukken wurde brûkt om in floeistofstream te kombinearjen of te splitsen. Threaded Pipe T-stukken hawwe deselde ynlaat- en útlaatmaten. Threaded T-fittings wurde brûkt yn ferskate yndustrytapassingen lykas gemyske ferwurking, oaljeraffinaderijen, petrochemyske en in protte oare yndustryen. Wy leverje ek smeide threaded T-stukken yn oanpaste grutte neffens de easken fan 'e klant. Wy produsearje threaded T-stukken mei ôfmjittings neffens ASME B16.11 / BS 3799. De B16.11-standert omfettet druk-temperatuerwurdearringen, ôfmjittings, markearring, tolerânsjes en materiaaleasken. Wy binne spesjalisearre yn it leverjen fan threaded T-stukken yn trije drukwurdearrings: klasse 2000, klasse 3000 en 6000 tsjin in ridlike priis yn Sina. Kontrolearje de ôfmjittingstabel foar threaded Pipe T-stukken foardat jo keapje.

ANSI/ASME B16.11 Threaded Pipe T-foarmige standertspesifikaasje

| Ofmjittings | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Grutte | 1/8″~4″ (DN6~DN100) |

| Klasse | 3000 pûn, 6000 pûn, 9000 pûn |

| Type | Moflassen (S/W) & SKROEFD (SCRD) – NPT, BSP, BSPT |

| Foarm | T-foarmich T-foarmich, T-foarmich piipt-T-foarmich, T-foarmich gelikense T-foarmich |

| Tsjinsten mei tafoege wearde: | Hjitgalvanisearjen, epoxy- en FBE-coating, elektropolijsten, sânstralen, triedsnijen, solderen |

| Produksjegraden: | RVS, Legeringstiel, Duplex, Nikkellegeringen, Leechtemperatuerstiel, Koalstofstiel, Cupronikkel |

Produksjenormen fan Threaded Equal T-stuk

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Materiaalklassen foar threaded T-shirts

RVS smeide triedden T-stuk:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Stiel Smeidde Threaded Gelikense T-foarm:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Smeidde triedde T-foarm fan koalstofstiel:

ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Smeid stiel mei triedden, gelikense T-foarm:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Smeid T-stuk mei skroefdraad fan koperlegering stiel: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

Nikkellegering smeid threaded gelikense T-foarm:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NIKKEL 200), UNS 2201 (NIKKEL 201) , UNS 4400 (MONEL 400 ) 02 (AL 400 ) 02 ), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

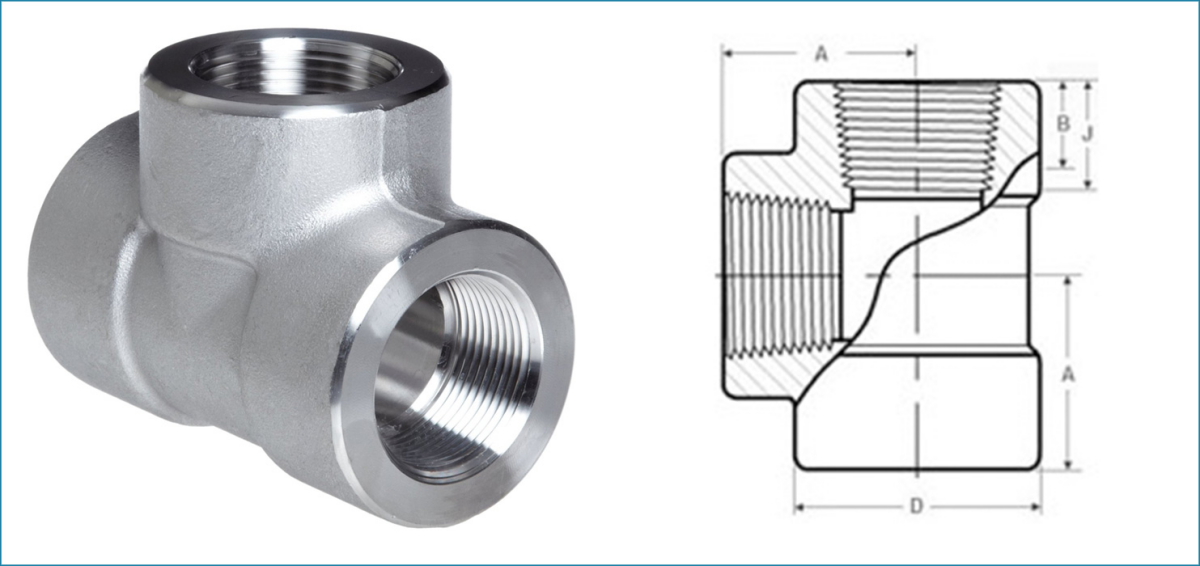

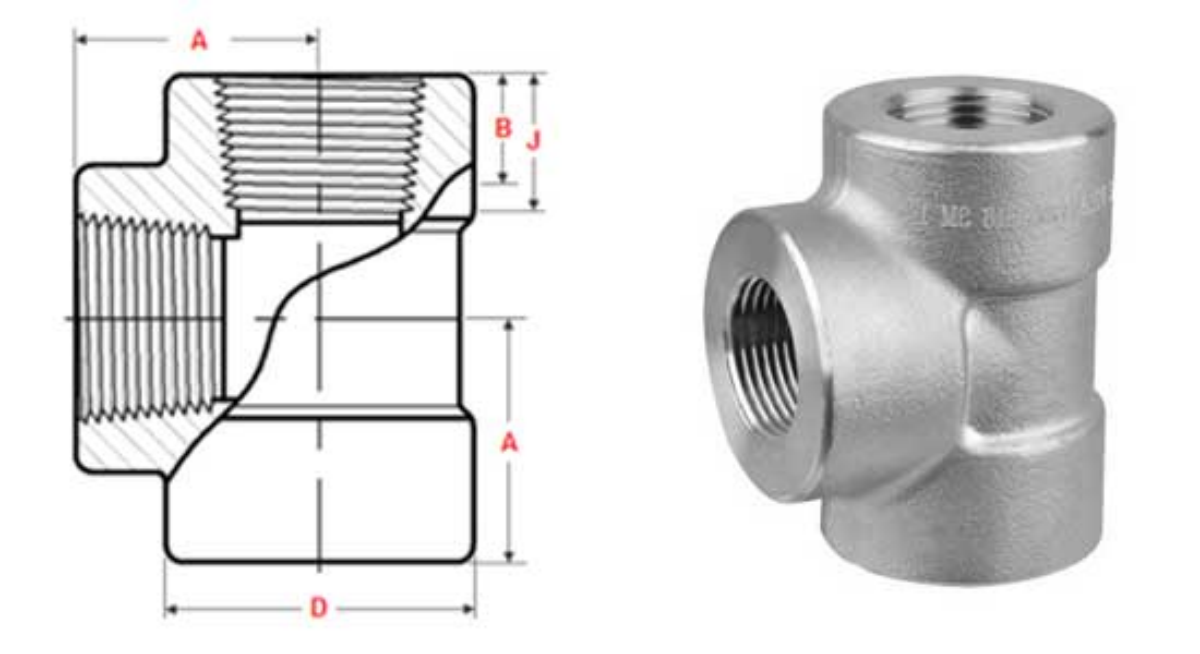

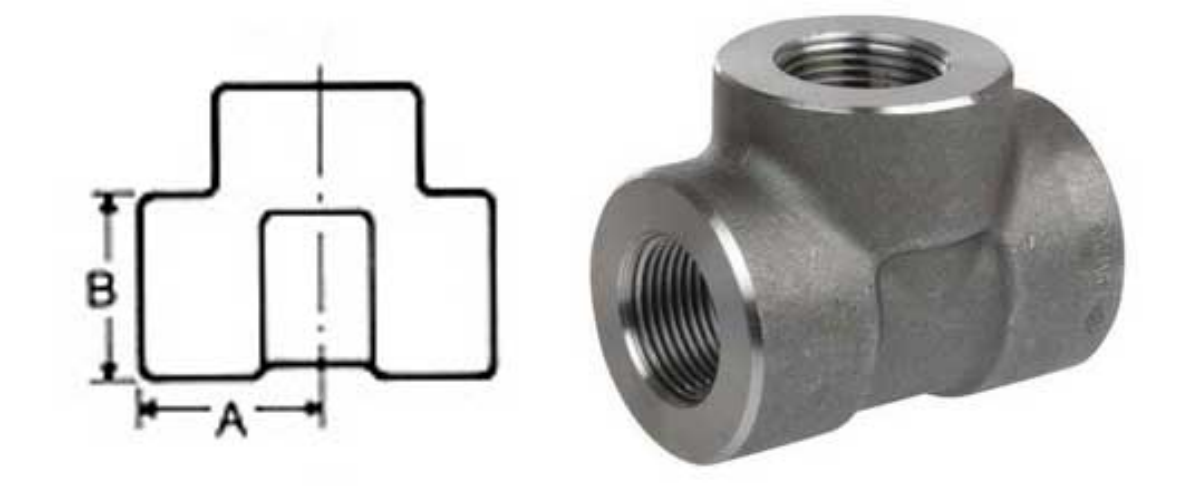

ANSI/ASME B16.11 SKRAAD T-DIMINSJES

Ofmjittingstabel foar skroefdraadpipen

Ofmjittings fan skroefdraad-T-stukken, 3/4 skroefdraad-T-stukken NPS 1/2 oant 4 Klasse 2000

| NPS | Min. lingte fan tried | Bûten Dia fan Band D | Sintrum nei ein A | Min. WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Gelikense T-foarm mei skroefdraad Klasse 3000 Ofmjittings NPS 1/2 oant 4

| NPS | Min. lingte fan tried | Bûten Dia fan Band D | Sintrum nei ein A | Min. WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

3/4 skroefdraad T-stuk ôfmjittings NPS 1/2 oant 4 klasse 6000

| NPS | Min. lingte fan tried | Bûten Dia fan Band D | Sintrum nei ein A | Min. WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Ofmjittings binne yn millimeters, útsein as oars oanjûn.

Diminsje B is de minimale lingte fan perfekte tried.

De lingte fan 'e brûkbere tried (B plus triedden mei folslein foarme woartels en platte toppen) moat net minder wêze as J.

| Klasse 2000 | Nominale piipgrutte | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.74 | 1.058 | 1.375 | 1.74 | 2.883 | 7.75 | 11.313 | 19.125 | |

|

| |||||||||||||

| Klasse 3000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.25 | 0.29 | 0.5 | 0.75 | 1.188 | 1.988 | 2.235 | 3 | 4.93 | 7.375 | 13.588 | 19.063 | |

|

| |||||||||||||

| Klasse 6000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3月4日 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.25 | 0.64 | 0.5 | 1.438 | 2.188 | 2.785 | 4.688 | 5.75 | 9.5 | 15 | |||

Smeidde Threaded / Skroefde Gelikense T-tapassing

ASME B16.11 Threaded T-stukken binne bekend om útsûnderlike prestaasjes te leverjen en wurde oer it algemien ûntwikkele foar

foldogge oan de easken. Wy biede in breed oanbod fan smeide skroefde T-stukken fia in wrâldwiid netwurk fan foarriedhâldende filialen. Dizze smeide skroefde T-stuk wurdt brûkt ynferskate yndustryen lykas:

RVS smeid threaded Tee brûkt yn oalje- en gaspipeline

Gebrûk fan smeide threaded T-stukken yn 'e gemyske yndustry

Gebrûk fan gelikense T-foarm fan legearingstiel yn loodgieterswurk

Smeidde skroefde gelikense T-foarm brûkt yn ferwaarming

Gebrûk fan smeide T-searjes yn wetterfoarsjenningssystemen

ANSI B16.11 Smeidde Threaded T-foarmige gebrûk yn krêftsintrale

Gebrûk fan gelikense T-sets foar threaded yn 'e papier- en pulpyndustry

Smeidde skroefde gelikense T-foarm brûkt yn algemiene tapassingen

Gebrûk fan smeide threaded T-stukken yn 'e fabrikaazjesektor

Gesmeid Geschroefde Gelikense Tee brûkt yn 'e Food Processing Industry

Smeid Threaded Equal Tee brûkt yn Strukturele Pipe