Socket Weld Cikakken haɗin gwiwa

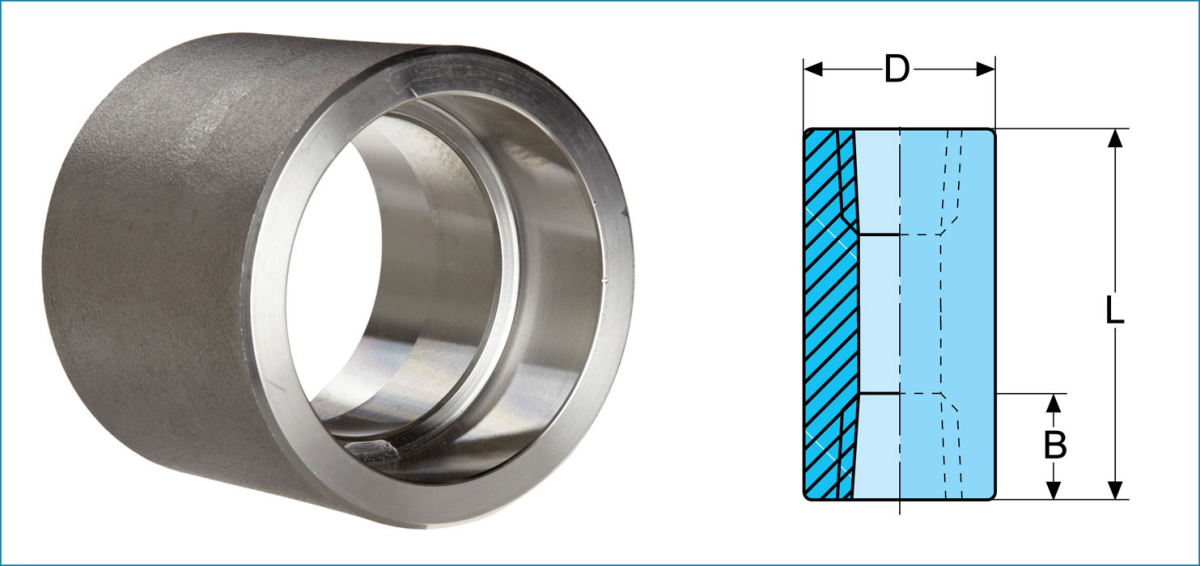

A matsayin ISO bokan kamfanin, Liaocheng Shenghao Metal Products Co., LTD ya shiga cikin kasa da kasa da kasuwanni a matsayin daya daga cikin manyan masu rarraba, maroki da stockist na Socket Weld Full Coupling. Socket Weld Full Couplings Ana amfani da su don haɗa ƙananan ƙararrawabututu a matsayin hasashe na tasirin walda akan bututun bututu. Dukan ƙarshen waɗannan Cikakkun Ma'aurata suna zaren zare. Ana buƙatar su sosai a cikin kasuwar haɗa bututu. Wadannan Bakin Karfe Socket Weld Half Couplings ana gwada su sosai don tabbatar da inganci da inganci.juriya a ƙarƙashin kowane matsanancin yanayi. Wadannan ANSI B16.11 Forged Socket Weld Full Couplings ana amfani da su a aikace-aikace kamar su Pharmaceuticals, shipbuilding, da dai sauransu HGFF Group Co., Ltd.abokan ciniki ASME B16.11 Forged Socket Weld Full Couplings a farashi mai ma'ana. Ana ba da su a cikin nau'i daban-daban da kauri don takamaiman bukatun abokan ciniki.

ANSI/ASME B16.11 Socket Weld Cikakken Ƙimar Haɗin Kai

Socket Weld Cikakken Girman Haɗawa

| Girma | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Girman | 1/8 ″ NB ZUWA 4″ NB |

| Ƙimar Matsi | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Siffar | Cikakkun Haɗaɗɗiya, Rage Haɗin Kai |

| Makin samarwa | Bakin Karfe, Alloy Karfe, Duplex, Nickel Alloys, Ƙananan zafin jiki Karfe, Carbon Karfe, Cupro Nickel |

Ka'idojin Kera Socket Weld Cikakken Haɗin Kai

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Jujjuyawar Socket Weld Cikakkun Makin Material Haɗaɗɗiya

Nickel Alloy Forged Socket Weld Cikakken Haɗin Kai:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400) UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

Bakin Karfe Jarumi Socket Weld Cikakken Haɗin Kai:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F 454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Karfe Forged Socket Weld Cikakken Haɗin Kai:

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Karfe Ford Socket Weld Cikakken Haɗin Kai:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Karfe Forged Socket Weld Cikakken Haɗin Kai:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR , 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Karfe Forged Socket Weld Cikakken Haɗin Kai: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 45/10), C 71500 (CU -NI- 70/30)

ASME B16.11 Forged Socket Weld Cikakken Nau'o'in Haɗawa

| Forged Socket weld Cikakken haɗin gwiwa | Socket Weld Cikakken Haɗaɗɗiyar Class 3000 |

| Socket Weld Rage Haɗin Kai | 3 4 Cikakkiyar Haɗin Socket Weld |

| ASME B16.11 Socket Weld Rage Haɗin Kai | 3000LB Socket Weld Cikakken haɗin gwiwa |

| ANSI B16.11 Forged Socket Weld Full Coupling | Class 6000 Socket Weld Cikakken Haɗin Kai |

| Socket Weld Cikakken Nauyin Haɗawa | BS 3799 Forged Socket Weld Full Coupling |

| Socket Weld Full Coupling Rage | High Quality Socket weld Cikakken haɗin gwiwa |

| 2 Cikakkiyar Haɗin Socket Weld | 1/2 Socket Weld Cikakken haɗin gwiwa |

| 3000# Forged Socket Weld Full Coupling | 3/4 Socket Weld Cikakken haɗin gwiwa |

| 5 Socket Weld Cikakken Haɗin Kai | 1 inch Socket Weld Cikakken haɗin gwiwa |

| 8 Cikakkiyar Haɗin Socket Weld | 2 inch Socket Weld Cikakken haɗin gwiwa |

| 6000# Socket Weld Full Coupling | 3 inch Socket Weld Cikakken haɗin gwiwa |

| 6 Cikakkiyar Haɗin Socket Weld | 6 inch Socket Weld Cikakken haɗin gwiwa |

ANSI/ASME B16.11 SOCKET WELD CIKAKKEN GIRMAMAWA

Socket Weld Rage Maɗaukakin Maɗaukaki

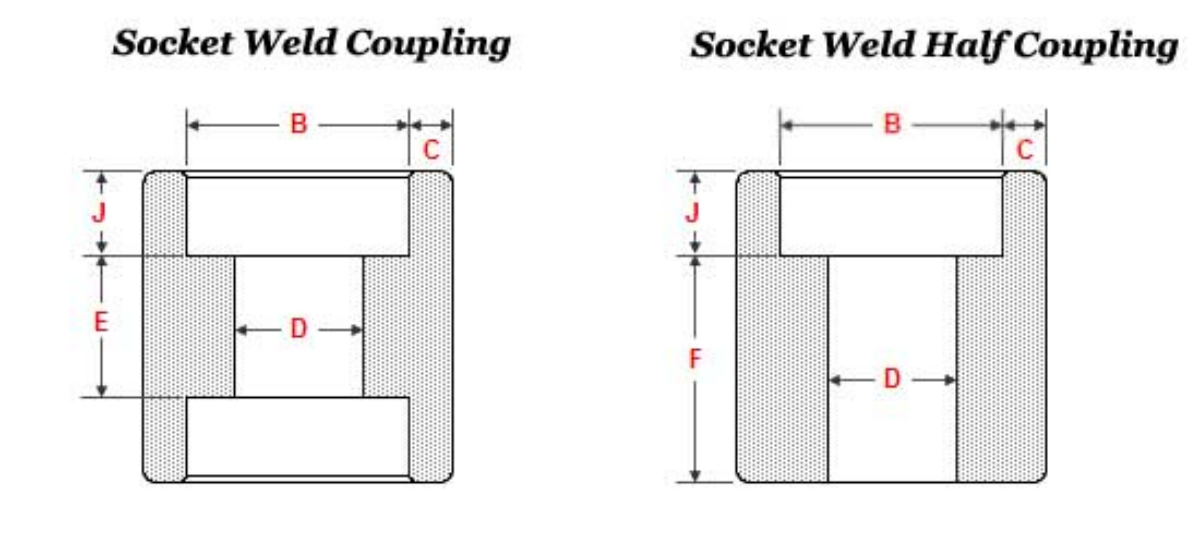

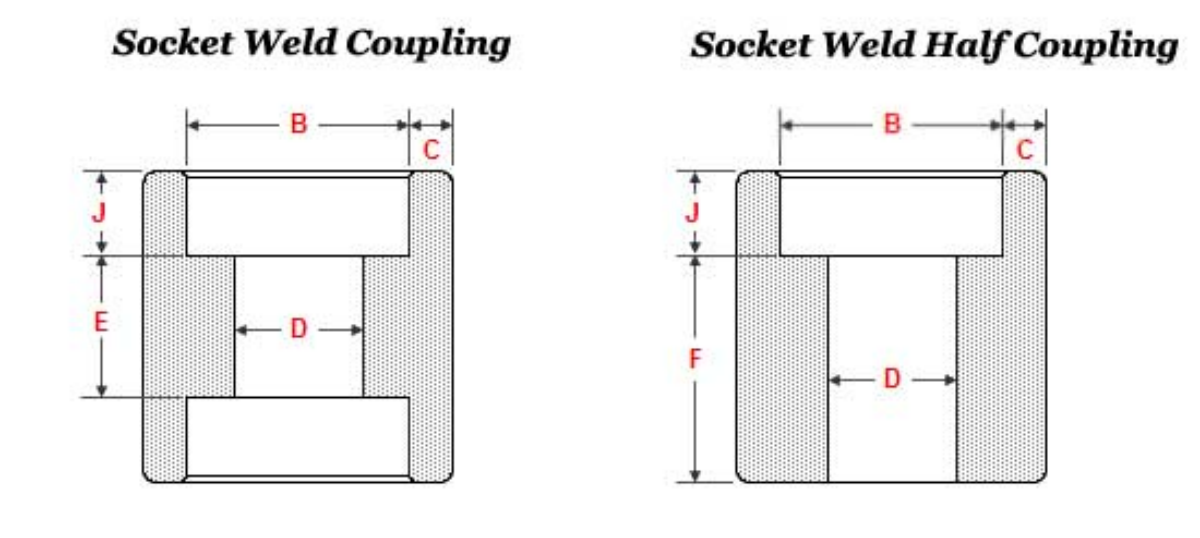

3000# Socket Weld Coupling Dimensions

| NPS | Socket Bore | Zurfin Socket | Bore DIA | Socket bango THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 | 4.65 4.10 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 | 4.90 4.25 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 | 5.70 5.00 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 | 6.05 5.30 |

| 1.1/2 | 48.90 48.65 | 13 | 41.7 40.1 | 6.35 5.55 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 | 6.95 6.05 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 | 8.75 7.65 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 | 9.50 8.30 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 | 10.70 9.35 |

| NPS | Kwanciya tsayi | |||

| Haɗin kai E | Rabin haɗin gwiwa F | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 | 47.5 | ||

6000# Socket Weld Coupling Dimensions

| NPS | Socket | Zurfin | Bore | Socket |

| B | J | D | C | |

| 1/2 | 21.95 | 10 | 12.5 | 5.95 |

| 3/4 | 27.30 | 13 | 16.3 | 6.95 |

| 1 | 34.05 | 13 | 21.5 | 7.90 |

| 1.1/4 | 42.80 | 13 | 30.2 | 7.90 |

| 1.1/2 | 48.90 | 13 | 34.7 | 8.90 |

| 2 | 61.35 | 16 | 43.6 | 10.90 |

| NPS | Kwanciya tsayi | |||

| Haɗin kai | Rabin haɗin gwiwa | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

Girman suna cikin millimeters sai dai in an nuna su.

Socket Bore (B) - Matsakaicin girma da mafi ƙarancin girma.

Diamita Bore (D) - Matsakaicin mafi girma da mafi ƙarancin girma.

Kaurin bangon soket – (C) – Matsakaicin kaurin bangon Socket.

Matsakaicin juriya na tsakiya zuwa kasan soket - (A)

NPS 1/2 da NPS 3/4 = +/- 1.5 mm

NPS 1 zuwa NPS 2 = +/- 2 mm

NPS 2.1/2 zuwa NPS 4 = +/- 2.5 mm