Socket Weld Union

A matsayin babban mai fitar da kayayyaki, mai rarrabawa kuma mai saka hannun jari na Socket Weld Union Fittings, Liaocheng Shenghao Metal Products Co., LTD. sun yi ƙoƙari akai-akai don samar da samfurori da yawa ga abokan cinikinsa. Kamfani ne da aka ba da takardar shedar ISO wanda ke ba da tabbacin cewa abokan cinikin su sun sami babban ingancisamfurori. Bakin Karfe Socket Weld Unions ana amfani da su a cikin ƙananan bututun da ake buƙata don wargaza bututun sau da yawa. Ƙirar Socket Weld Ƙirar Ƙirar Ƙira ce ta haɗin gwiwa. Ya ƙunshi guda uku masu haɗin kai. Wannan madaidaicin yana da zaren ciki guda biyu da tsakiya wanda ke zana ƙarshen tare lokacin juyawa. Domin yirage warping na kujeru, ƙungiyoyi ya kamata a dunƙule sosai kafin a welded karshen. ANSI B16.11 Socket Weld UnionAna samun kayan aiki a cikin masu girma dabam bisa ga buƙatun abokan ciniki. HGFF Group Co., Ltd yana samar da Socket ba tare da lahani baƘungiyoyin Weld don samar da matuƙar dacewa ga abokan cinikinta.

ANSI/ASME B16.11 Socket Weld Union Standard Specification

| Girma | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Girman | 1/8 ″ NB ZUWA 4″ NB |

| Ƙimar Matsi | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Siffar | Socket Weld Union, Socket Weld Pipe Union, Socket Weld Orifice Union, Ƙungiya Ƙarfafa, Socket Weld Union Fittings |

| Makin samarwa | Bakin Karfe, Alloy Karfe, Duplex, Nickel Alloys, Ƙarfe mai ƙarancin zafi, Karfe Karfe, Cupro Nickel |

Ka'idojin Kera Socket Weld Union Fittings

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Jarrabawar Socket Weld Union Material maki

Nickel Alloy Forged Socket Weld Union :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400) UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

Bakin Karfe Forged Socket Weld Union :

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F 454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Karfe Forged Socket Weld Union:

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Karfe Forged Socket Weld Union:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Karfe Forged Socket Weld Union :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR , 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Karfe Forged Socket Weld Union: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 45/10), C 71500 (CU -NI- 70/30)

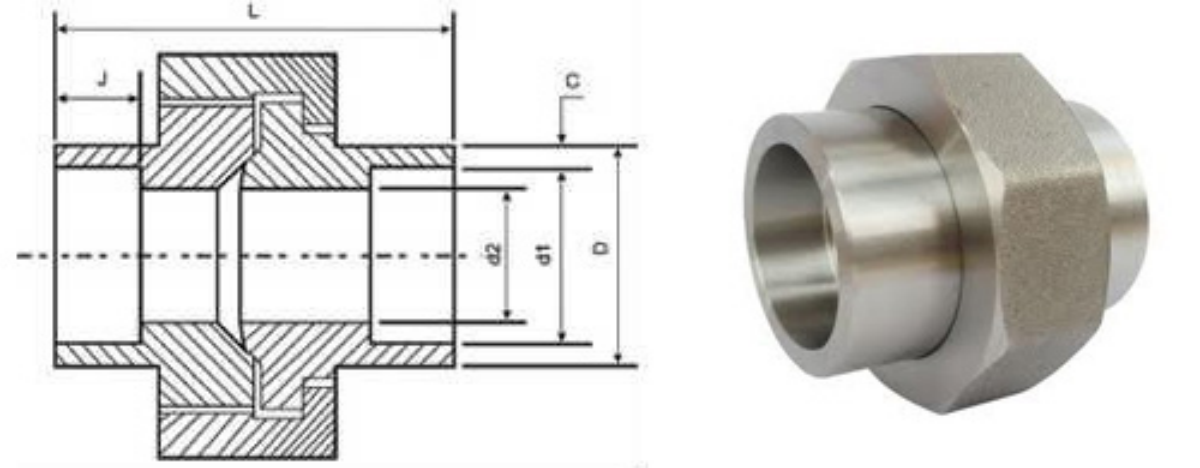

ANSI/ASME B16.11 SOCKET WELD UNION DIMENSIONS

Socket Weld Pipe Union Dimensions

| Diamita na Suna | Waje Diamita | Kaurin bango | Socket Bore | Hanyar ruwa Bore | Zurfin Socket | Tsawon Taron | |||

| Dmin | Cmin | d1 | d2 | Jmin | L | ||||

| DN | NPS | Socket | Zare | Socket | Zare | Socket | Socket & Zare | Socket | Socket & Zare |

| 6 | 1/8 | 21.8 | 14.7 | 3.2 | 2.5 | 10.65 | 6.43 | 10 | 41.4 |

| 8 | 1/4 | 21.8 | 19.0 | 3.3 | 3.1 | 14.10 | 9.45 | 10 | 41.4 |

| 10 | 3/8 | 25.9 | 22.9 | 3.5 | 3.2 | 17.55 | 13.51 | 10 | 46.0 |

| 15 | 1/2 | 31.2 | 27.7 | 4.1 | 3.8 | 21.70 | 17.07 | 10 | 49.0 |

| 20 | 3/4 | 37.1 | 33.5 | 4.3 | 4.0 | 27.05 | 21.39 | 13 | 56.9 |

| 25 | 1 | 45.5 | 41.4 | 5.0 | 4.6 | 33.80 | 27.74 | 13 | 62.0 |

| 32 | 11/4 | 54.9 | 50.5 | 5.3 | 4.9 | 42.55 | 35.36 | 13 | 71.1 |

| 40 | 11/2 | 61.5 | 57.2 | 5.6 | 5.1 | 48.65 | 41.20 | 13 | 76.5 |

| 50 | 2 | 75.2 | 70.1 | 6.1 | 5.6 | 61.10 | 52.12 | 16 | 86.1 |

| 65 | 21/2 | 91.7 | 85.3 | 7.7 | 7.1 | 73.80 | 64.31 | 16 | 102.4 |

| 80 | 3 | 109.2 | 102.4 | 8.4 | 7.7 | 89.80 | 77.27 | 16 | 109.0 |

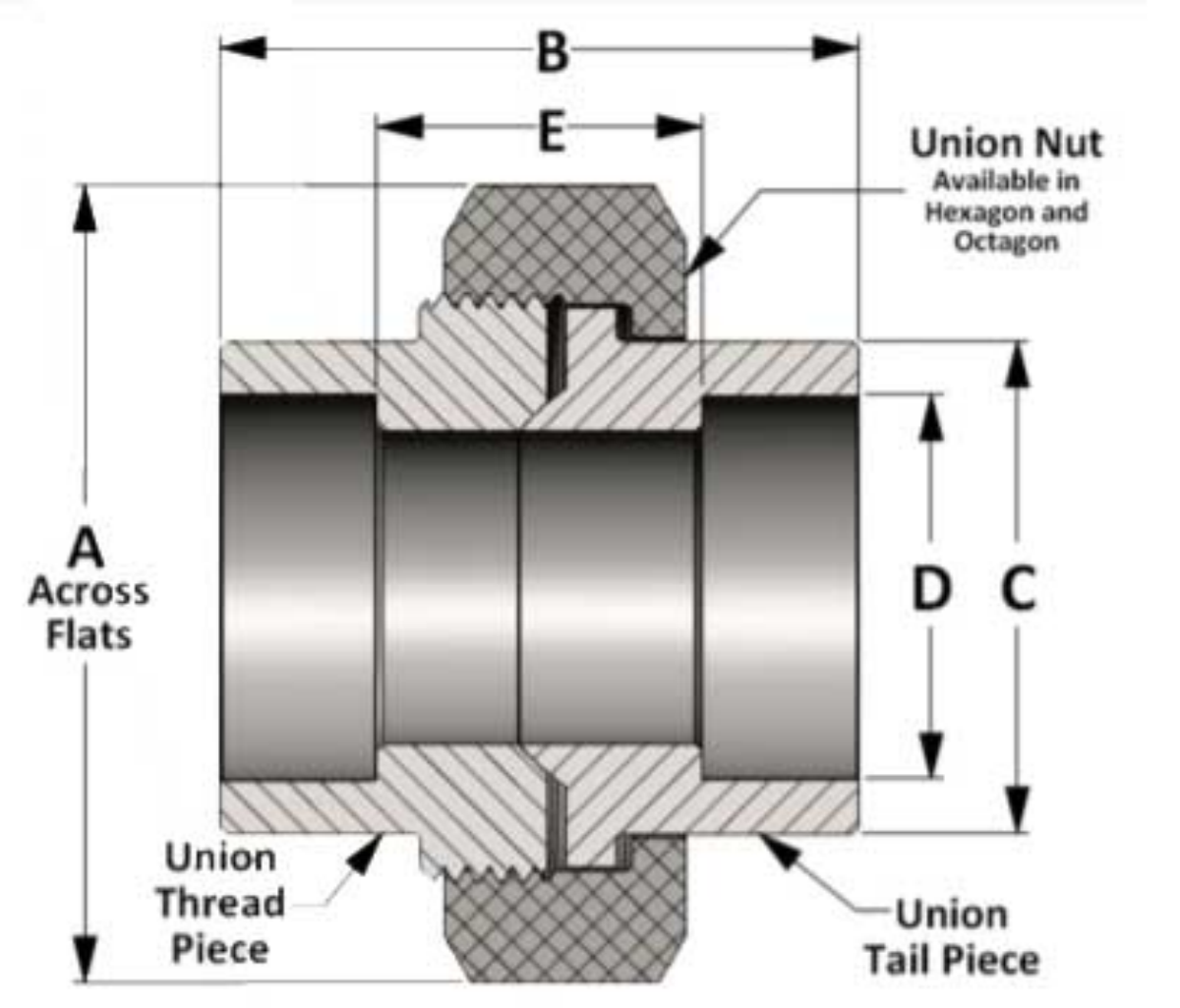

Socket Weld Union Weight2 Socket Weld Union

| CLASS 3000 Socket Weld Union | ||||||||||||

| GIRMAN PIPE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 |

| B | 1.688 | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 |

| C | 0.865 | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | 4.545 |

| E | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 2.313 | 5.000 |

| LBS | 0.40 | 0.38 | 0.52 | 0.73 | 1.19 | 1.66 | 2.66 | 3.42 | 5.36 | 9.12 | 12.58 | 17.50 |

| CLASS 6000 Socket Weld Union | ||||||||||||

| GIRMAN PIPE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 | - |

| B | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 | - |

| C | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 | - |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | - |

| E | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 5.750 | - |

| LBS | 0.48 | 0.56 | 0.75 | 1.35 | 2.01 | 3.17 | 3.92 | 6.60 | 10.12 | 14.00 | 40.891 | - |

| CLASS 9000 Socket Weld Union | ||||||||||||

| GIRMAN PIPE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.750 | 2.000 | 2.250 | 2.563 | 3.063 | 3.688 | 4.313 | 5.000 | 5.750 | 6.875 | - | - |

| B | 2.500 | 2.563 | 2.938 | 3.250 | 3.750 | 4.000 | 4.625 | 4.813 | 5.563 | 6.25 | - | - |

| C | 1.000 | 1.250 | 1.500 | 1.750 | 2.250 | 2.500 | 3.000 | 3.625 | 4.250 | 5.000 | - | - |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | - | - |

| E | 1.720 | 1.688 | 1.938 | 2.000 | 2.375 | 2.375 | 3.000 | 2.938 | 3.188 | 3.750 | - | - |

| LBS | 0.89 | 1.045 | 1.955 | 3.29 | 5.34 | 7.99 | 12.73 | 18.34 | 26.36 | 37.07 | - | |

Ƙirƙirar Socket Weld Pipe Cap Application

ASME B16.11 Socket weld Pipe Cap an san su don sadar da ayyuka na musamman kuma gabaɗaya ana haɓaka su

domin biyan bukatun. Muna ba da kewayon Forged Socket weld Pipe Cap ta hanyar hanyar sadarwa ta duniya

na rassan hannun jari. Ana amfani da wannan Forged Socket weld Pipe Cap a iri-irimasana'antu kamar:

Bakin Karfe Forged Socket Weld Pipe Cap yana amfani da bututun mai da iskar gas

Forged Socket weld Pipe Cap Ana amfani da shi a Masana'antar Sinadari

Alloy Karfe Socket weld Pipe Cap yana amfani dashi a cikin aikin famfo

Karshen Socket Weld Ƙarshen bututun da ake amfani da shi wajen dumama

Socket weld Forged Pipe Caps ana amfani da su a Tsarin Samar da Ruwa

ANSI B16.11 Forged Socket weld Pipe Cap yana amfani dashi a cikin Shuka Wuta

Socket weld Pipe Cap yana amfani da shi a cikin Masana'antar Takarda & Bangaranci

Ƙwararrun Socket weld Pipe Caps ana amfani da su a Gabaɗaya Makasudin Aikace-aikace

Forged Socket weld Pipe Cap Ana amfani da shi a Masana'antar Kera

Forged Socket weld Pipe Cap Ana amfani da shi a Masana'antar sarrafa Abinci

Ƙwararrun Socket weld Ƙwayoyin bututu suna amfani da su a cikin bututun Tsarin