Tee Utas / Screwed

Liaocheng Shenghao Metal products Co., LTD punika Produsèn Highly diakoni saka ASME B16.11 Threaded Tee, kang banget tahan kanggo karat kimia lan oksidasi (tahan korosi), lan wis sawetara efektifitas kaku-pecah dhuwur lan tingkat creep kurang ing nandheske dhuwur ing Suhu sawise perawatan panas cocok. Threaded Equal Tee digunakake kanggo gabungke utawa pamisah aliran fluida. Threaded Pipe Tee nduweni ukuran inlet lan outlet sing padha. Fitting Tee Utas digunakake ing macem-macem aplikasi industri kaya pangolahan kimia, kilang minyak, petrokimia lan akeh industri liyane. Kita uga nyedhiyakake Forged Threaded Tee kanthi ukuran sing disesuaikan miturut kabutuhan pelanggan. Kita nggawe Ukuran Tee Utas sesuai karo ASME B16.11 / BS 3799. Standar B16.11 nyakup rating suhu tekanan, dimensi, tandha, toleransi lan syarat materi. Kita khusus nyedhiyakake Tee Utas ing telung rating tekanan: kelas 2000, Kelas 3000 lan 6000 kanthi rega sing cukup ing China. Priksa Bagan Dimensi Tee Pipa Utas sadurunge tuku.

ANSI/ASME B16.11 Threaded Pipe Tee Spesifikasi Standar

| ukuran | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Ukuran | 1/8″~4″ (DN6~DN100) |

| kelas | 3000 LBS, 6000 LBS, 9000 LBS |

| Jinis | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Wangun | Tee Utas, Tee Pipa Utas, Tee Utas Equal |

| Layanan Tambah Nilai: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Kelas Produksi: | Baja tahan karat, Baja Paduan, Dupleks, Paduan Nikel, Baja Suhu Rendah, Baja Karbon, Nikel Cupro |

Standar Manufaktur saka Threaded Equal Tee

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Kelas Bahan Tee Utas ASME B16.11

Stainless Steel Tempa Ulir Tee:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321, F321, F321, F321, F321H F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Threaded Tee Equal:

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Baja Karbon Forged Threaded Tee:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Baja Paduan Tempa Ulir Equal Tee:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 CR2, 1/4 CR, 1 CR2, 1/4 CR 91

Tembaga Paduan Baja Tempa Ulir Tee : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30)

Nikel Alloy Forged Threaded Equal Tee:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS ALL 200 UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625), UNS 10276 (HASTELOY C 276)

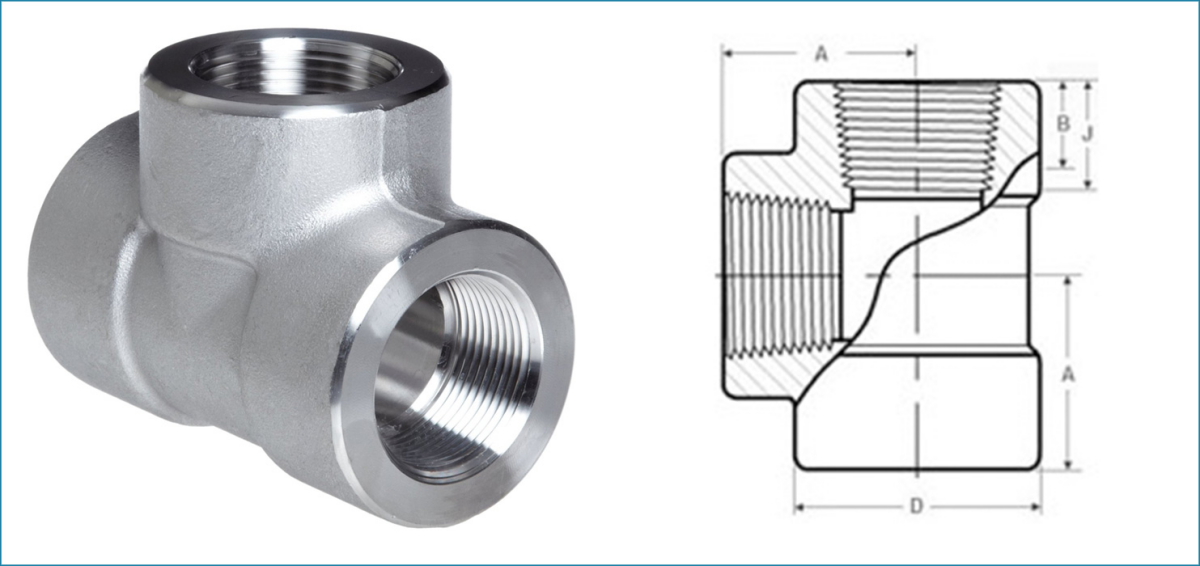

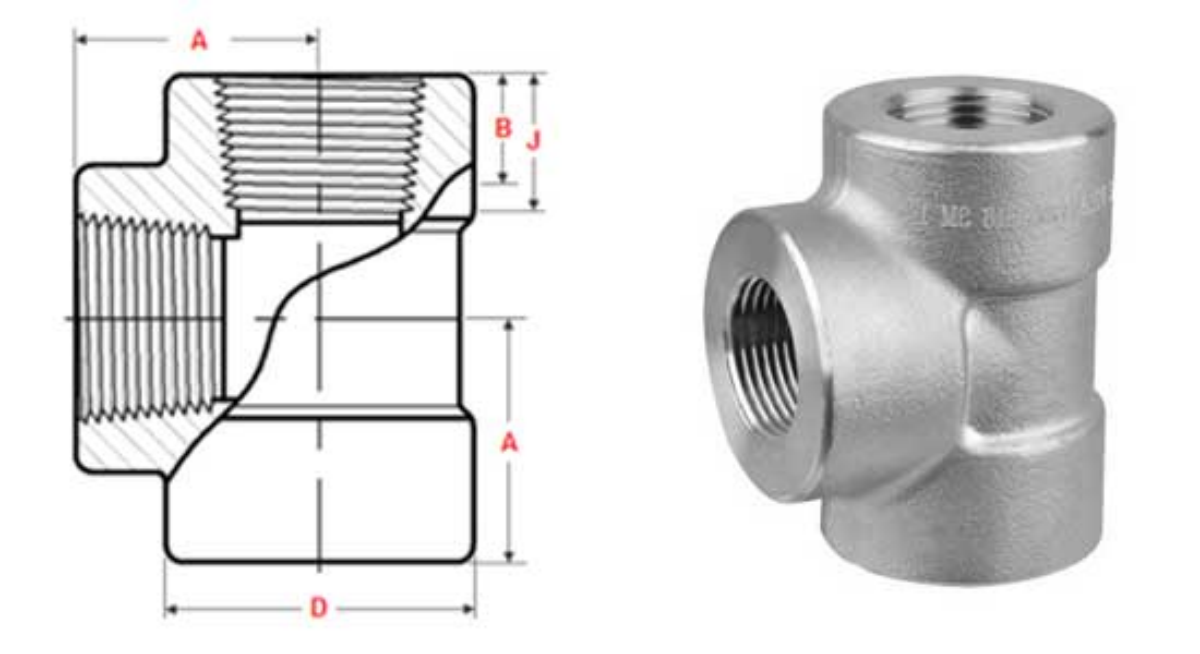

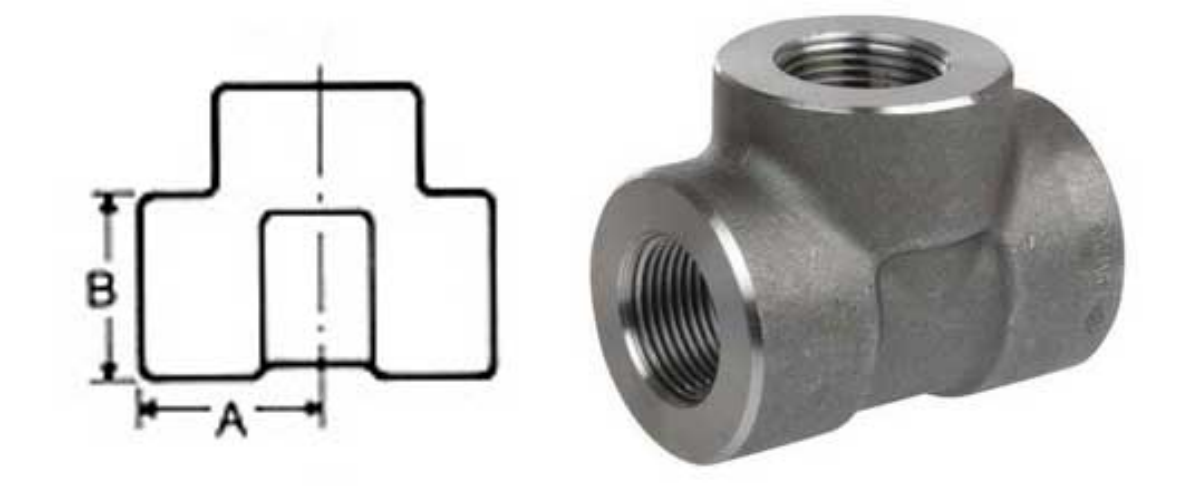

ANSI / ASME B16.11 DIMENSI TEE Utas

Bagan Dimensi Tee Pipa Utas

Dimensi Tee Ulir, Dimensi Tee Ulir 3/4 NPS 1/2 nganti 4 Kelas 2000

| NPS | Min Length of Thread | Njaba Dia saka Band D | Pusat nganti Pungkasan A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Utas Equal Tee Kelas 3000 Dimensi NPS 1/2 nganti 4

| NPS | Min Length of Thread | Njaba Dia saka Band D | Pusat nganti Pungkasan A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

Ukuran Tee Utas 3/4 NPS 1/2 nganti 4 Kelas 6000

| NPS | Min Length of Thread | Njaba Dia saka Band D | Pusat nganti Pungkasan A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Ukuran ana ing millimeter kajaba dituduhake.

Dimensi B yaiku dawa minimal benang sing sampurna.

Dawane benang sing migunani (B ditambah benang kanthi oyod sing kabentuk lan pucuk rata) ora kurang saka J.

| Kelas 2000 | Ukuran Pipa Nominal | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.74 | 1.058 | 1.375 | 1.74 | 2.883 | 7.75 | 11.313 | 19.125 | |

|

| |||||||||||||

| Kelas 3000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.25 | 0.29 | 0.5 | 0.75 | 1.188 | 1.988 | 2.235 | 3 | 4.93 | 7.375 | 13.588 | 19.063 | |

|

| |||||||||||||

| Kelas 6000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3月4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.25 | 0.64 | 0.5 | 1.438 | 2.188 | 2.785 | 4.688 | 5.75 | 9.5 | 15 | |||

Forged Threaded / Screwed Equal Tee Aplikasi

ASME B16.11 Utas Tee dikenal kanggo ngirim kinerja ngédap lan umume dikembangaké kanggo

nyukupi panjaluk. Kita nawakake macem-macem Tee Screwed Forged liwat jaringan cabang nyimpen saham ing saindenging jagad. Tee Utas Forged iki digunakake ingmacem-macem industri kayata:

Stainless Steel Forged Threaded Tee digunakake ing Pipa Minyak lan Gas

Forged Threaded Tee digunakake ing Industri Kimia

Alloy Steel Threaded Equal Tee digunakake ing Plumbing

Forged Screwed Equal Tee digunakake ing Pemanasan

Threaded Forged Tee digunakake ing Sistem Pasokan Banyu

ANSI B16.11 Tee Utas Palsu digunakake ing Pembangkit Listrik

Utas Equal Tee digunakake ing Industri Kertas & Pulp

Forged Screwed Equal Tee digunakake ing Aplikasi Tujuan Umum

Forged Threaded Tee digunakake ing Industri Fabrikasi

Forged Screwed Equal Tee digunakake ing Industri Pangolahan Pangan

Forged Threaded Equal Tee digunakake ing Pipa Struktural