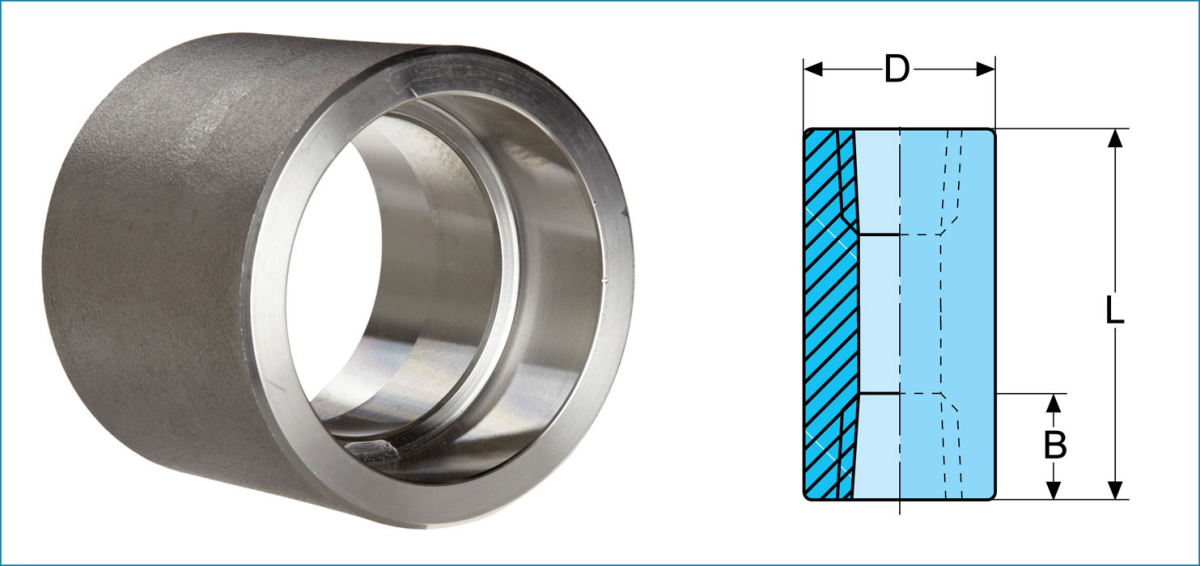

Socket Weld Full Coupling

Wekî pargîdaniyek pejirandî ISO, Liaocheng Shenghao Metal Products Co., LTD, wekî yek ji belavker, dabînker û pargîdaniya sereke ya Socket Weld Full Coupling, rê li bazarên neteweyî û navneteweyî girt. Socket Weld Full Couplings ji bo girêdana boriyên piçûk têne bikar anînlûleyên wekî projeyek bandorek weldingê li ser boriyê boriyê. Herdu dawiya van Hevgirêdanên Tevahî bi xêzkirî ne. Ew di sûka pêvekirina boriyê de pir tê xwestin. Van Nîv Hevgirêdanên Weldê yên Soket Pola zengarnegir bi hişk têne ceribandin da ku kalîteya herî bilind û misoger bikin.bîhnfirehiya di bin her şert û mercên giran de. Van ANSI B16.11 Hevgirêdanên Tevahiya Socket Weld ên Çêkirî di sepanên wekî dermanxane, çêkirina keştiyan, hwd de têne bikar anîn. HGFF Group Co., Ltd.mişteriyên ASME B16.11 Couplings Full Socket Weld Forged Bi bihayên maqûl. Ew ji bo hewcedariyên taybetî yên xerîdar di mezinahî û qalindahiya cûda de têne peyda kirin.

ANSI / ASME B16.11 Socket Weld Full Coupling Standard Specification

Socket Weld Full Coupling Sizes

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Mezinayî | 1/8″ NB HETA 4″ NB |

| Rêjeyên zextê | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Şikil | Coupling Full, Kêmkirina Coupling |

| Notên hilberînê | Stainless Steel, Alloy Steel, Duplex, Alloys Nikel, Steel Germiya Nizm, Karbon Steel, Cupro Nikel |

Manufacturing Standards of Socket Weld Full Coupling

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Çêbû Socket Weld Full Coupling Maddî Notên

Nîkel Alloy Forged Socket Weld Coupling Full:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 / 200) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Têkiliya Tevahiya Pêveka Weldê ya Çêkirî ya Stainless:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321,24, F321 F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld Coupling Full:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Pêvekirina Tevahiya Pêveka Weldê ya Karbon Steel:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Tevhevkirina Tevahiya Weldê Socket Forged Alloy Steel:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR , 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Socket Weld Coupling Full: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 45/10), C 71500 ( CU -NI- 70/30)

ASME B16.11 Forged Socket Weld Coupling Full Available Types

| Forged Socket weld Full Coupling | Socket Weld Full Coupling Class 3000 |

| Socket Weld Kêmkirina Coupling | 3 4 Socket Weld Full Coupling |

| ASME B16.11 Socket Weld Kêmkirina Coupling | 3000LB Socket Weld Coupling Full |

| ANSI B16.11 Çêbû Socket Weld Full Coupling | Class 6000 Socket Weld Full Coupling |

| Socket Weld Full Coupling Weight | BS 3799 Çêbû Socket Weld Full Coupling |

| Socket Weld Full Coupling Reducers | High Quality Socket weld Full Coupling |

| 2 Socket Weld Full Coupling | 1/2 Socket Weld Full Coupling |

| 3000# Çêbû Socket Weld Full Coupling | 3/4 Socket Weld Full Coupling |

| 5 Socket Weld Coupling Full | 1 inch Socket Weld Full Coupling |

| 8 Socket Weld Full Coupling | 2 inch Socket Weld Full Coupling |

| 6000 # Socket Weld Coupling Full | 3 inch Socket Weld Full Coupling |

| 6 Socket Weld Full Coupling | 6 inch Socket Weld Full Coupling |

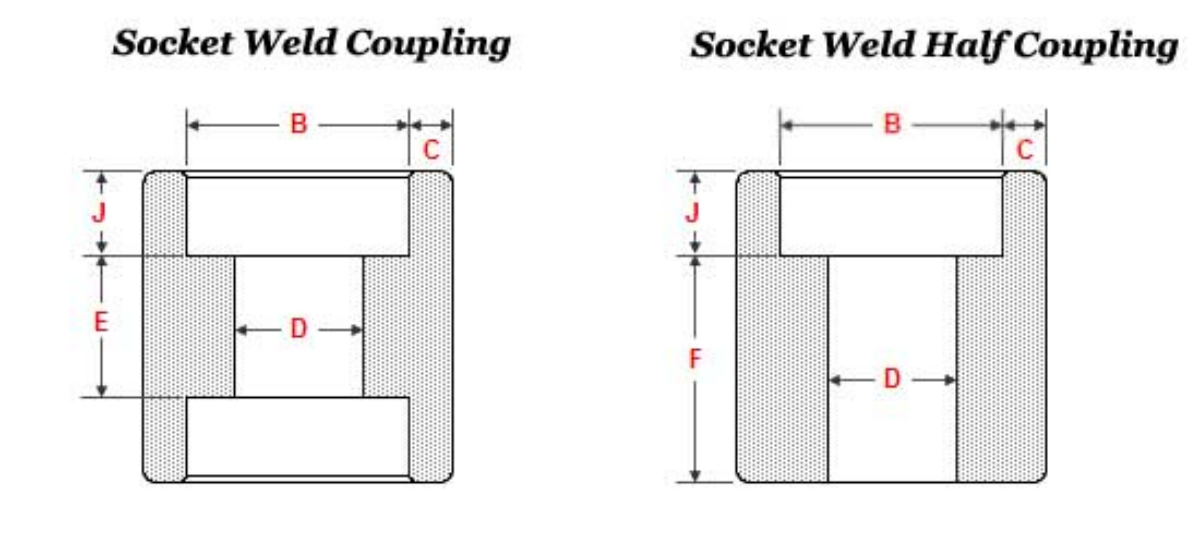

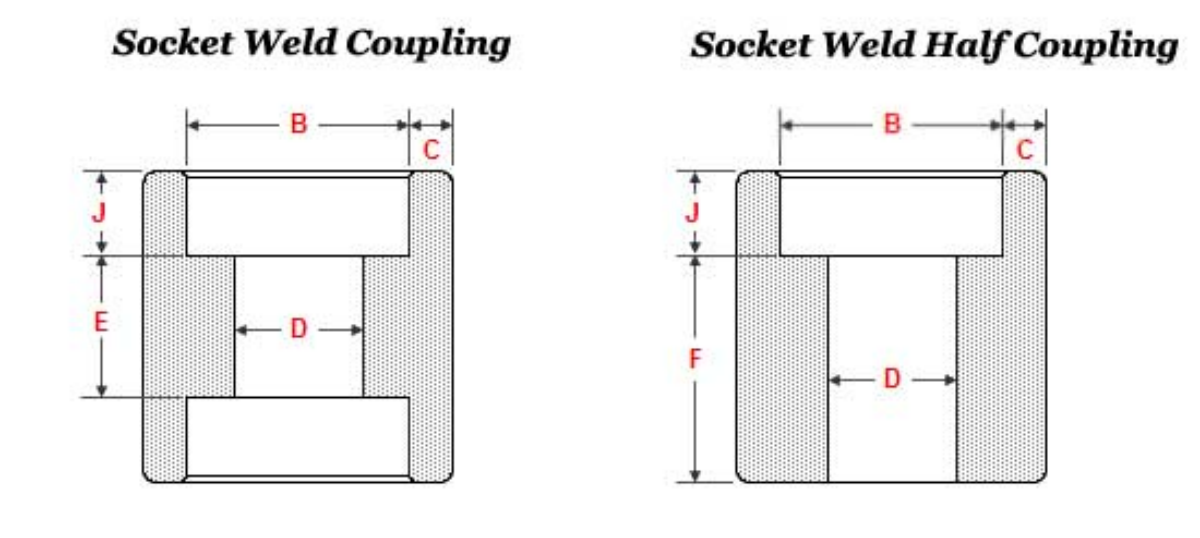

ANSI/ASME B16.11 SOCKET WELD MEZINÊN TEMA HÊVÎNÊ

Socket Weld Kêmkirina Dimensions Coupling

3000 # Socket Weld Coupling Dimensions

| NPS | Qûlka çav Kolîn | Kûrî Qûlka çav | Kolîn DIA | Qûlka çav dîwar THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 | 4.65 4.10 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 | 4.90 4.25 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 | 5.70 5.00 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 | 6.05 5.30 |

| 1.1/2 | 48.90 48,65 | 13 | 41.7 40.1 | 6.35 5.55 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 | 6.95 6.05 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 | 8.75 7.65 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 | 9.50 8.30 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 | 10.70 9.35 |

| NPS | Dirêjahî danîn | |||

| Coupling E | Nîv hevgirtin F | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 | 47.5 | ||

6000 # Socket Weld Coupling Dimensions

| NPS | Qûlka çav | Kûrî | Kolîn | Qûlka çav |

| B | J | D | C | |

| 1/2 | 21.95 | 10 | 12.5 | 5.95 |

| 3/4 | 27.30 | 13 | 16.3 | 6.95 |

| 1 | 34.05 | 13 | 21.5 | 7.90 |

| 1.1/4 | 42.80 | 13 | 30.2 | 7.90 |

| 1.1/2 | 48.90 | 13 | 34.7 | 8.90 |

| 2 | 61.35 | 16 | 43.6 | 10.90 |

| NPS | Dirêjahî danîn | |||

| Coupling | Nîv hevgirtin | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

Pîvan bi milîmetre ne heya ku wekî din neyê destnîşan kirin.

Socket Bore (B) - Pîvana herî zêde û hindiktirîn.

Dirêjahiya Borê (D) - Pîvana herî zêde û herî kêm.

Qalindahiya dîwarê soketê - (C) - Navînî stûrahiya dîwarê soketê.

Navenda toleransên dimensîyonî li binê soketê - (A)

NPS 1/2 û NPS 3/4 = +/- 1,5 mm

NPS 1 ber NPS 2 = +/- 2 mm

NPS 2.1/2 ber NPS 4 = +/- 2.5 mm