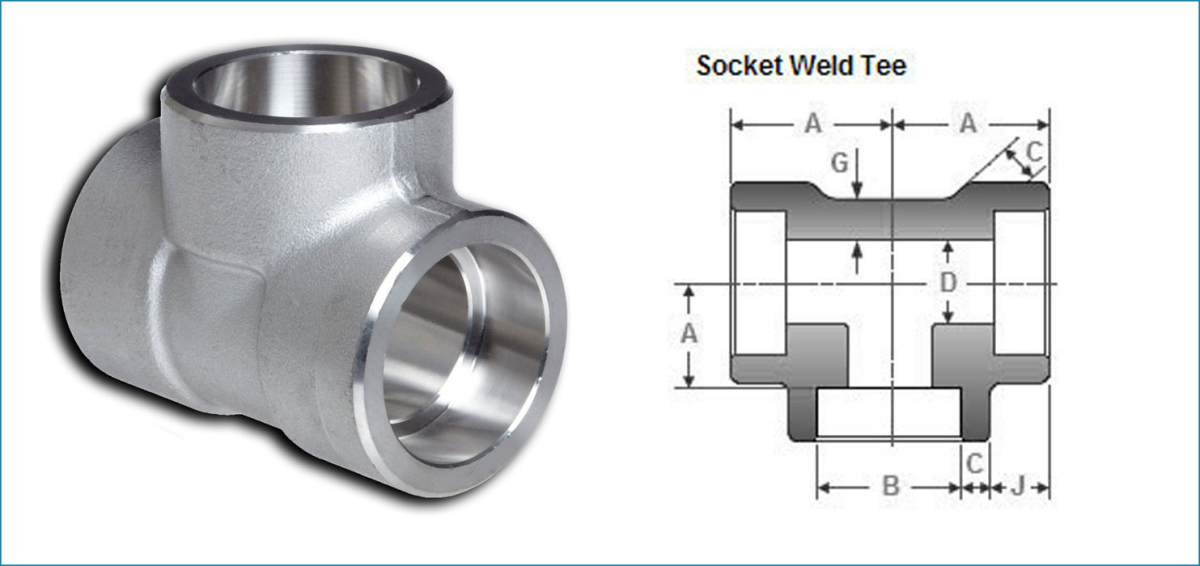

Socket Weld Tee

Liaocheng Shenghao productorum Metallorum Co., LTD auctoritativa est fabrica, supplementum et exportatorem ASME B16.11 Socket Weld Tee, fabricatum ut per ambitum qualitatis internationalis. Nostra Socket Weld Tee Fittings in variis generibus et materialibus gradibus pro variis applicationibus industriae incidit. Nostrum oblatum Forged Socket Weld Aequale Tee facit 90° ramum e principali fistulae procursu.

Has Socket Weld Tees ad varias applicationes industriales sicut processui chemicae, oleum repurgationum, petrochemicarum et multarum aliarum industriarum suppeditamus. ANSI B16.11 Falsa Socket Weld Tee est lacus probatio et corrosio repugnans. Socket Weld Aequales Tees adhibentur ad lineas toxicas deportantes materiam flammabilem vel pretiosam ubi nullae lacus permitti potest, et pro vapore 300 ad 600 PSI.

ANSI/ASME B16.11 Socket Weld Tee Standard Specification

| Dimensiones | ASME 16.11, MSS SP-79, MSS. SP-95, 83, 95, 97, BS |

| Magnitudo | 1/2″NB TO 4″NB IN |

| Classis | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socket Weld (S/W) & SCREWED (SCRD) - NPT, BSP, BSPT |

| Forma | Sockte Weld Tee, Socket Weld Aequalis Tee |

| Productio Grades | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Ferrum, Carbon Steel, Cupro Nickel |

Signa vestibulum Vestibulum Weld Aequalis Tee

| ASME: | ASME 16.11, MSS SP-79, MSS. SP-95, 83, 95, 97, BS |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Composuerunt Intel Weld Tee Material Grades

Nickel Alloy Forged Socket Weld Tee:

ASTM / ASME SB 336 , ASTM / ASME SB 564 / 160 / 163 / 472 , UNS 2200 ( NICKEL 200 ) , UNS 2201 ( NICKEL 201 ) , UNS 4400 ( MONEL 400 ) , UNS 8020 , UNS INCONELIUS (825), UNS

Steel Forged Socket Weld Tee:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F347, F347, F TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld Tee :

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Socket Weld Tee:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Admisce Steel Forged Socket Weld Tee:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR , 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Socket Weld Tee : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

ASME B16.11 Forged Socket Weld Tee Available Genera

| Falsa est Socket pugillo Tee | Socket Welding Reducing Tee |

| 150 Ib Socket Weld Fittings Pipe Tee | 2 inch Socket pugillo Tee |

| ASME B16.11 Socket pugil Aequalis Tee | 3000LB Socket Weld Tee |

| Taberna Weld Tee Fittings | genus (VI) Pentium Weld Forged Tee |

| ANSI B16.11 Forged Socket Weld Tee | BS MMMDCCXCIX Forged Socket Weld Tee |

| Falsa est Socket pugil Aequalis Tee | Socket Weld Aequalis Tee Pondus |

| Tabulæ pugillo Tee Reducer | High Quality Pentium pugillo Tee |

| I inch Socket Weld Tee | Socket Weld Pipe Tee |

ASME B16.11 Forded nervum Weld XC Deg Cubitus Available Genera

| Ulna XC Degree finxerunt Intel pugillo | Composuerunt Socket pugil Long Radius 90 Gradus Cubitus |

| 150 Ib Socket Weld Fittings Pipe Cubitus | Tabernaculi pugillo XC° Brevis Radius Cubitus |

| ASME B16.11 90 gradus Socket pugiles Cubitus | 90 Gradus Cubitus 3000LB Socket Weld |

| Tabule Weld Fittings XC Degree Pipe Cubitus | Long Badius Socket Weld 90 Deg. Composuerunt Cubita |

| ANSI B16.11 90 Gradus Forged Cubitus | BS 3799 Forged 90 Gradus Cubitus |

| Supposititius Socket pugil XC Deg Cubitus | Tabulæ pugillo XC ° Pipe Cubitus |

| Tabernae iunctae 90deg. Cubitus | High Quality Socket pugil XC ° Cubitus |

| XC ° Socket Weld Cubitus | Tabernae Weld XC cubiti |

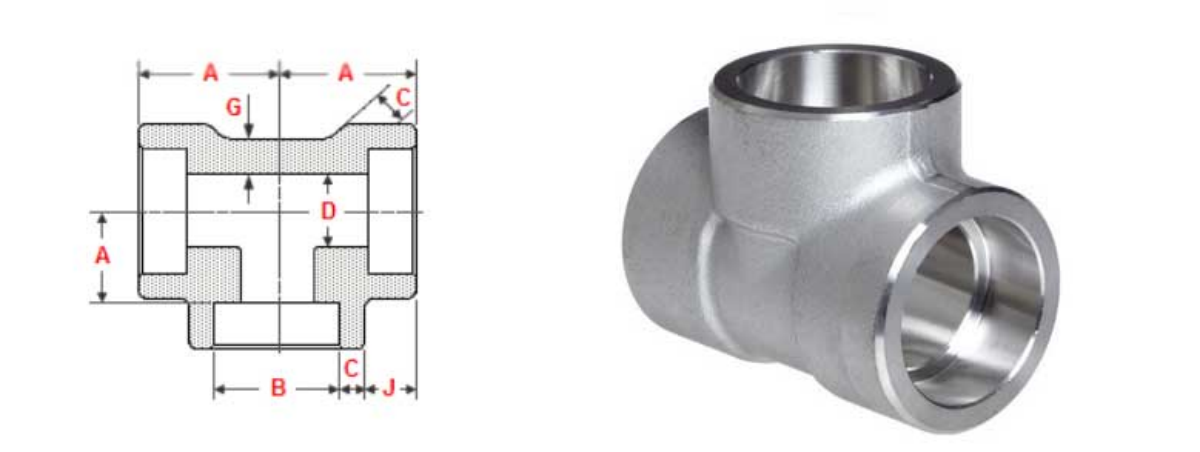

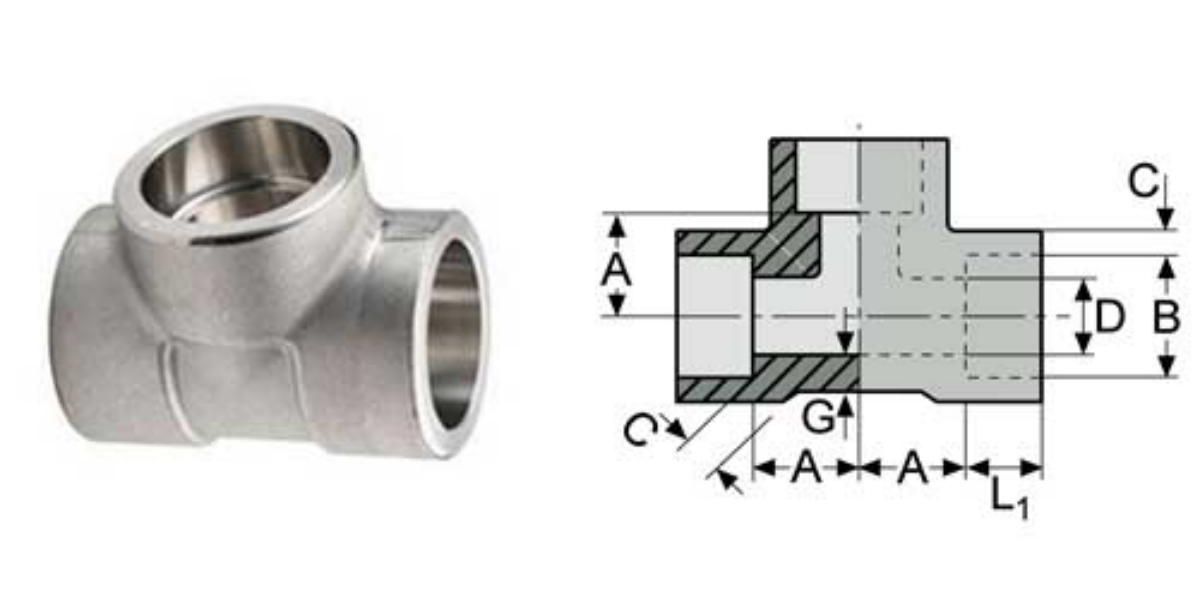

ANSI/ASME B16.11 CAVUS CONFERRUMINO Tee DIMENSIONES

Socket Weld Aequalis Tee Dimensiones

Classis 3000 Socket Weld Tee Dimensiones NPS 1/2 ad 2

| NPS | Socket Bore | Profundum Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 | 13 | 41.7 40.1 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 | 3.75 | 15.5 |

| 3/4 | 4.90 4.25 | 3.90 | 19.5 |

| 1 | 5.70 5.00 | 4.55 | 22 |

| 1.1/4 | 6.05 5.30 | 4.85 | 27 |

| 1.1/2 | 6.35 5.55 | 5.10 | 32 |

| 2 | 6.95 6.05 | 5.55 | 38 |

| 2.1/2 | 8.75 7.65 | 7.00 | 41.5 |

| 3 | 9.50 8.30 | 7.60 | 57.5 |

| 4 | 10.70 9.35 | 8.55 | 66.5 |

Classis 6000 Socket Weld Tee Dimensiones NPS 1/2 ad 2

| NPS | Socket Bore | Profundum Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 | 10 | 12.5 11 |

| 3/4 | 27.30 27.05 | 13 | 16.3 14.8 |

| 1 | 34.05 33.80 | 13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 | 13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 | 13 | 34.7 33.2 |

| 2 | 61.35 61.10 | 16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 | 4.80 | 19.5 |

| 3/4 | 6.95 6.05 | 5.55 | 22.5 |

| 1 | 7.90 6.95 | 6.35 | 27 |

| 1.1/4 | 7.90 6.95 | 6.35 | 32 |

| 1.1/2 | 8.90 7.80 | 7.15 | 38 |

| 2 | 10.90 9.50 | 8.75 | 41 |

Dimensiones in millimetrorum sunt, nisi aliud notetur.

Socket Bore (B) - dimensiones maximas et minimas.

Portabat Diameter (D) - Maximas et minimas dimensiones.

Murus nervus crassitudo — (C) — Mediocris muri crassitudo nervus.

Dimensiones tolerances centrum ad fundum tabernaculi - (A)

NPS 1/2 et NPS 3/4 = +/- 1.5 mm

NPS 1 ad NPS 2 = +/- 2 mm

NPS 2.1/2 ad NPS 4 = +/- 2.5 mm

Tabernaculi pugil Aequalis Tee Pondus

| Nominal pipe magnitudine | B | L1 | C | G | D | A | Pondus |

| in. | mm | nervus | mm | mm | mm | mm | ~kg/pce |

| 1/4 | 14.20 | 9.53 | 3.30 | 3.02 | 8.86 | 11.11 | 0.11 |

| 1 | 33.90 | 12.50 | 4.98 | 4.55 | 26.26 | 22.23 | 0.65 |

Socket fictus Application Tee

ASME B16.11 45 Gradus Socket pugillo Tee notum est ad eximiam observantiam liberandam et fere

developed pro occurrens postulata. Debemus latitudine Forged 45 Degree Intel pugillo Tee per a

the worldwide network of stock-keing branches. Haec 45Deg. Taberna pugillaribus Tee variis industriis adhibetur ut:

XXXXV Steel ° Forde Tee utitur in oleo et Gas Pipeline

XLV Die Forde Pipe Tee utitur in chemica Industry

Admisce Steel XLV ° Tee utitur in Plumbing

Composuerunt XLV Degree Pipe Tee utitur in Heating

45 Degree Forged Tee uses in Water Supple Systems

ANSI B16.9 Ford XLV ° Pipe Tee utitur in potentia Planta

45° Tee utitur in Paper & Pulpam Industry

XLV° Degree Tee utitur in proposito Applications

Composuerunt 45° Long Radius Tee utitur in Fabrication Industry

XLV Die Forde Tee utitur in Cibus Processing Industry

Radius Te utitur in structuris Pipe