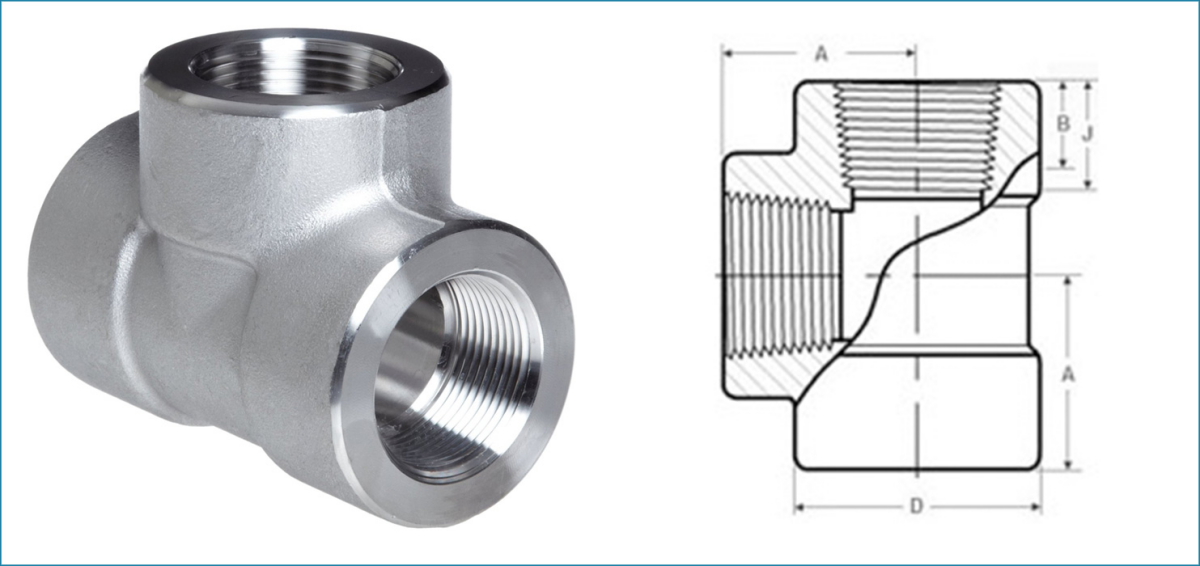

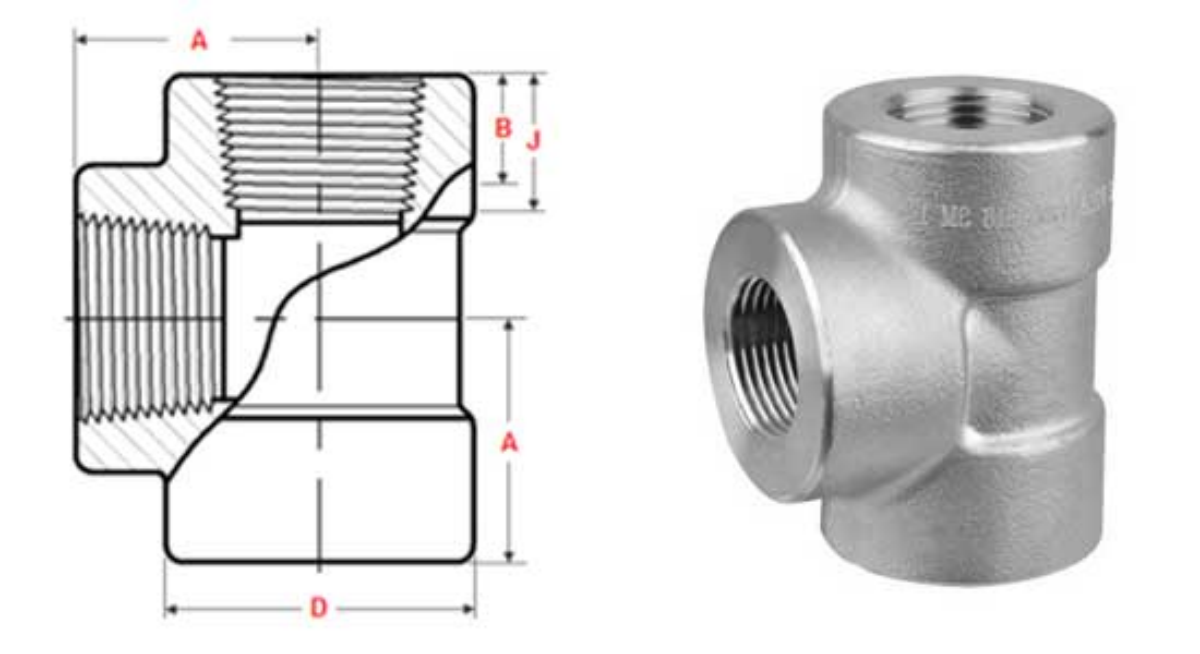

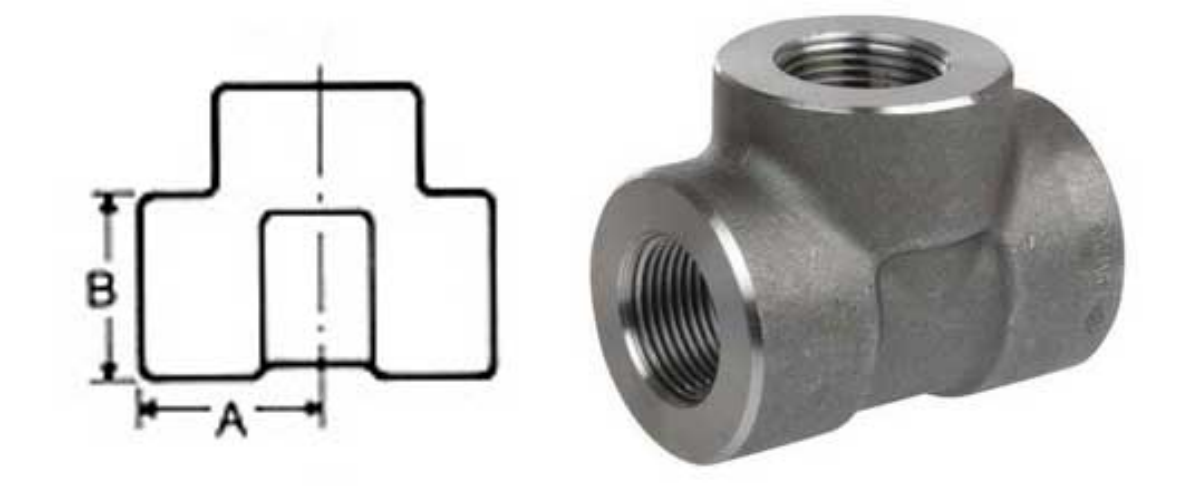

Post / Screwed Tee

Liaocheng Shenghao productorum Metallorum Co., LTD opificem maxime acclamatum est ASME B16.11 Threaded Tee, quod valde repugnans est corrosioni chemicae et oxidationis (corrosioni resistentis), et habet efficaciam aliquam altam vis rupturae et humiles rates sub alto subrepentes extollit temperaturas post tractationem idoneam caloris. Sequela Aequalis Tee vel ad fluxum fluidum componendum vel scindendum adhibetur. Pipe Tee Threaded eundem diverticulum et exitus magnitudinum habet. Thread Tee Fittings in diversis applicationibus industriis utuntur sicut processus chemici, oleum repurgationum, petrochemical et multae aliae industriae. Nos quoque suppeditamus fictae Tee Threaded in magnitudine nativus sicut per mos postulationem. Treaded Tee Dimensiones fabricamus secundum ASME B16.11/BS 3799. Vexillum B16.11 pressionis temperaturae aestimationes, dimensiones, notationes, tolerantias et materialia requisita operit. Nos speciales sumus in praebenda Threaded Tee in tribus pressionibus ratings: classis 2000, classis 3000 et 6000 rationabili pretio in Sinis. Reprehendo Threaded Pipe Tee Dimensiones Chartae ante emere.

ANSI/ASME B16.11 Threaded Pipe Tee Standard Specification

| Dimensiones | ASME 16.11, MSS SP-79, MSS. SP-95, 83, 95, 97, BS |

| Magnitudo | 1/8″~4″ (DN6~DN100) |

| Classis | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socket Weld (S/W) & SCREWED (SCRD) - NPT, BSP, BSPT |

| Forma | Post Tee, Pipe Threaded Tee, sequela Aequalis Tee |

| Precium Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering. |

| Gradus productio: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Ferrum, Carbon Steel, Cupro Nickel |

Signa vestibulum Aequalis Threaded Tee

| ASME: | ASME 16.11, MSS SP-79, MSS. SP-95, 83, 95, 97, BS |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Threaded Grades Tee Material

Steel Forged Threaded Tee:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F347, F347, F340 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Ferro Forged Threaded Equal Tee:

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Ferro Forded Threaded Tee:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Admisce Ferro Forged Threaded Aequalis Tee:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR , 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Threaded Tee : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

Nickel Alloy Forded Threaded Aequalis Tee:

ASTM / ASME SB 336 , ASTM / ASME SB 564 / 160 / 163 / 472 , UNS 2200 ( NICKEL 200 ) , UNS 2201 ( NICKEL 201 ) , UNS 4400 ( MONEL 400 ) , UNS 8020 , UNS INCONELIUS (825), UNS

ANSI/ASME B16.11 THREADED Tee DIMENSIONES

Re Pipe Tee Dimensiones Chartae

Post Tee Dimensiones, 3/4 Threaded Tee Dimensiones NPS 1/2 ad IV Classis MM

| NPS | Min Longitudo sequelae | Extra Dia Band D | Centrum usque ad finem A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Threaded Aequalis Tee Classis MMM Dimensiones NPS 1/2 ad 4

| NPS | Min Longitudo sequelae | Extra Dia Band D | Centrum usque ad finem A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

3/4 Threaded Tee Dimensiones NPS 1/2 ad IV Classis 6000

| NPS | Min Longitudo sequelae | Extra Dia Band D | Centrum usque ad finem A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Dimensiones in millimetrorum sunt, nisi aliud notetur.

Dimensio B est minima longitudo stamina perfecta.

Longitudo filorum utilium (B plus staminum cum radicibus plene formatis et cristis planis) non minus quam J.

| Classis 2000 | Nominal Pipe Size | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | - | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | - | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | - | 0.188 | 0.236 | 0.435 | 0.74 | 1.058 | 1.375 | 1.74 | 2.883 | 7.75 | 11.313 | 19.125 | |

|

| |||||||||||||

| Classis 3000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.25 | 0.29 | 0.5 | 0.75 | 1.188 | 1.988 | 2.235 | 3 | 4.93 | 7.375 | 13.588 | 19.063 | |

|

| |||||||||||||

| Classis 6000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | - | |

| F | 3月4日 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | - | |

| Wt | 0.25 | 0.64 | 0.5 | 1.438 | 2.188 | 2.785 | 4.688 | 5.75 | 9.5 | 15 | |||

Falsa PM / Screwed Equal Tee Application

ASME B16.11 Threaded Tee notum est ad eximiam observantiam liberandam et plerumque excultam

occurrens postulata. Offerimus latitudinem Ford Screwed Tee per orbem retis stirpibus custodiendis. Hoc falsum Threaded Tee est usus invariis industries sicut:

Steel Forged Threaded Tee utitur in oleo et Gas Pipeline

Composuerunt Threaded Tee utitur in Industry Chemical

Admisce Ferro Threaded Equal Tee utitur in Plumbing

Composuit Screwed Equal Tee utitur in Heating

Threaded Forged Tee uses in Water Supple Systems

ANSI B16.11 Forded Threaded T utitur in potentia Planta

Re par Tee utitur in Paper & Pulp Industry

Composuit Screwed Equal Tee utitur in proposito Applications

Composuerunt Threaded T utitur in fabricatione Industry

Composuit Screwed Equal Tee utitur in Food Processing Industry

Falsa Threaded Aequalis Tee utitur in Pipe structuralis