Steckdosen-Schweissunioun

Als féierende Exportateur, Distributeur a Lagerhändler vu Socket Weld Union Fittings huet Liaocheng Shenghao Metal products Co., LTD. sech konsequent beméit, hire Clienten eng breet Palette vu Produkter ze bidden. Et ass eng ISO-zertifizéiert Firma, déi garantéiert, datt hir Clienten héichqualitativ Produkter kréien.Produkter. Schweissunitéiten aus Edelstol ginn a Leitunge mat Nidderdrock benotzt, wou d'Päif dacks ofmontéiert muss ginn. Eng geschmied Schweissunitéit ass e Schraufverbindungsdesign. Si besteet aus dräi matenee verbonnenen Deeler. Dës Fitting huet zwee bannenzeg Gewënn an e Mëttelstéck, dat d'Ennen zesummezitt, wann se gedréit gëtt. Fir...Fir d'Verformung vun de Sëtzer ze minimiséieren, sollten d'Verbindungen fest geschrauft ginn, ier d'Enn geschweesst gëtt. ANSI B16.11 Socket Weld UnionArmaturen sinn a personaliséierbare Gréissten no de Wënsch vun de Clienten verfügbar. HGFF Group Co., Ltd produzéiert ouni Problemer Socket-Fittings.Schweessuniounen, fir senge Clienten ultimativen Komfort ze bidden.

ANSI/ASME B16.11 Socket Weld Union Standard Spezifikatioun

| Dimensiounen | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Gréisst | 1/8″ NB BIS 4″ NB |

| Drockbewäertungen | 2000 Pond, 3000 Pond, 6000 Pond, 9000 Pond |

| Formulaire | Sockelschweissunioun, Sockelschweissrohrunioun, Sockelschweissöffnungsunioun, geschmiedte Unioun, Sockelschweissuniounsarmaturen |

| Produktiounsqualitéiten | Edelstol, Legierungsstol, Duplex, Nickellegierungen, Niddertemperaturstol, Kuelestol, Cupro-Nickel |

Fabrikatiounsnormen vu Socket Weld Union Fittings

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| LU: | EN10253-1, EN10253-2 |

Geschmiedte Socket Weld Union Materialqualitéiten

Geschmiedete Muffeschweissunioun aus Nickellegierung:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400 ) 02, UNS 2200 ), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Geschmiedete Schweissstéck aus Edelstol:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Stol geschmiedte Muffeschweissunioun:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Schmiedeverbindung aus geschmiedtem Kuelestol:

ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Geschmiedete Steckdosenverbindung aus Legierungsstahl:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Geschmiedete Muffeschweissunioun aus Kupferlegierungstahl: ASTM / ASME SB 111 UNS Nr. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS Nr. C 70600 (CU-NI- 45/10), C 71500 (CU-NI- 70/30)

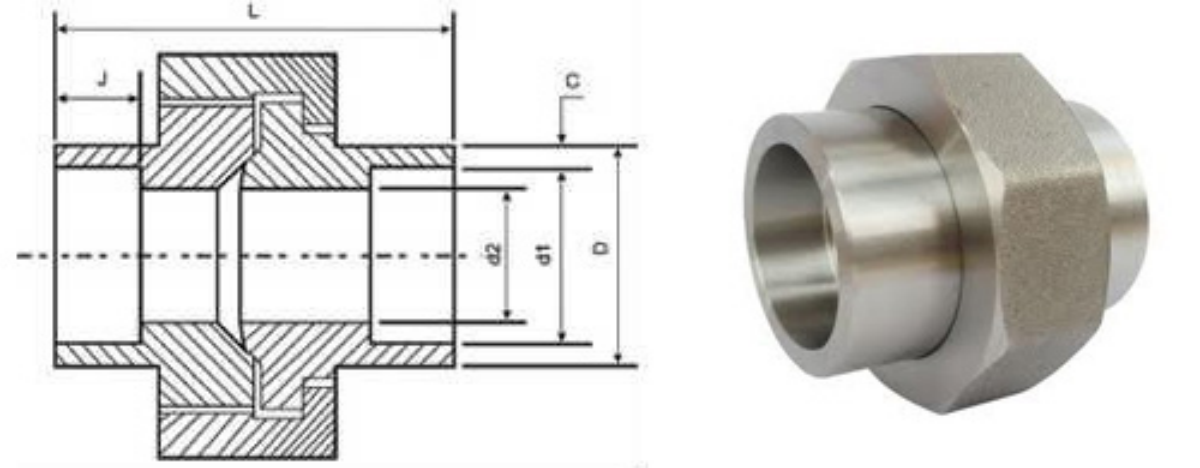

DIMENSIOUNEN VUN DER ANSI/ASME B16.11 SCHWEISUNIOUN VUN DER SCHLUSSSTOFF

Dimensiounen vun der Schweißrohrverbindung

| Nominellen Duerchmiesser | Äusseren Duerchmiesser | Wanddicke | Steckdosenbohrung | Waasserwee Buer | Déift vum Steckdous | Längt Assembl | |||

| Dmin | Cmin | d1 | d2 | Jmin | L | ||||

| DN | NPS | Steckdos | Gewinde | Steckdos | Gewinde | Steckdos | Steckdosen & Gewinde | Steckdos | Steckdosen & Gewinde |

| 6 | 1/8 | 21.8 | 14.7 | 3.2 | 2,5 | 10,65 | 6.43 | 10 | 41,4 |

| 8 | 1/4 | 21.8 | 19.0 | 3.3 | 3.1 | 14.10 | 9.45 | 10 | 41,4 |

| 10 | 3/8 | 25,9 | 22,9 | 3.5 | 3.2 | 17.55 | 13,51 | 10 | 46,0 |

| 15 | 1/2 | 31.2 | 27,7 | 4.1 | 3.8 | 21,70 | 17.07 | 10 | 49,0 |

| 20 | 3/4 | 37.1 | 33,5 | 4.3 | 4.0 | 27.05 | 21.39 | 13 | 56,9 |

| 25 | 1 | 45,5 | 41,4 | 5.0 | 4.6 | 33,80 | 27,74 | 13 | 62,0 |

| 32 | 11/4 | 54,9 | 50,5 | 5.3 | 4.9 | 42,55 | 35,36 | 13 | 71.1 |

| 40 | 11/2 | 61,5 | 57,2 | 5.6 | 5.1 | 48,65 | 41.20 | 13 | 76,5 |

| 50 | 2 | 75,2 | 70.1 | 6.1 | 5.6 | 61.10 | 52,12 | 16 | 86,1 |

| 65 | 21/2 | 91,7 | 85,3 | 7.7 | 7.1 | 73,80 | 64,31 | 16 | 102,4 |

| 80 | 3 | 109.2 | 102,4 | 8.4 | 7.7 | 89,80 | 77,27 | 16 | 109.0 |

Gewiicht vun der Schweißunioun fir d'Sch ...

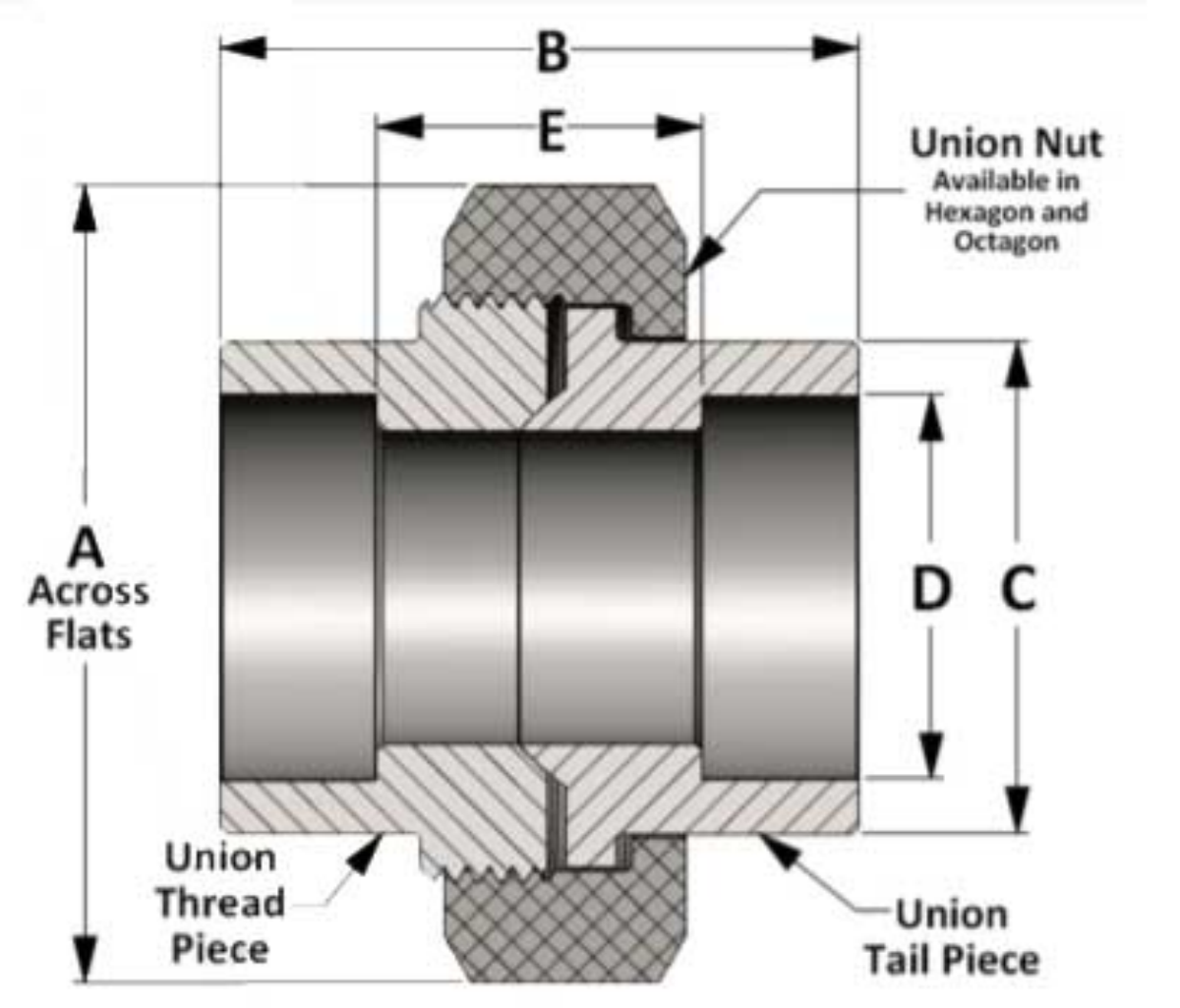

| KLASS 3000 Schweissunioun | ||||||||||||

| Päifgréisst | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 |

| B | 1.688 | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2,813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 |

| C | 0,865 | 0,865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2,965 | 3.615 | 4.305 | 5.415 |

| D | 0,426 | 0,560 | 0,693 | 0,859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | 4.545 |

| E | 0,813 | 0,813 | 0,938 | 0,938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 2.313 | 5.000 |

| LBS | 0,40 | 0,38 | 0,52 | 0,73 | 1.19 | 1,66 | 2,66 | 3,42 | 5,36 | 9.12 | 12,58 | 17,50 |

| KLASS 6000 Schweissunioun fir d'Muffin | ||||||||||||

| Päifgréisst | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 | — |

| B | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2,813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 | — |

| C | 0,865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2,965 | 3.615 | 4.305 | 5.415 | — |

| D | 0,426 | 0,560 | 0,693 | 0,859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | — |

| E | 0,813 | 0,813 | 0,938 | 0,938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 5.750 | — |

| LBS | 0,48 | 0,56 | 0,75 | 1,35 | 2.01 | 3.17 | 3,92 | 6,60 | 10.12 | 14.00 Auer | 40.891 | — |

| KLASS 9000 Schweissunioun fir d'Muffin | ||||||||||||

| Päifgréisst | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.750 | 2.000 | 2.250 | 2,563 | 3.063 | 3.688 | 4.313 | 5.000 | 5.750 | 6.875 | — | — |

| B | 2.500 | 2,563 | 2.938 | 3.250 | 3.750 | 4.000 | 4.625 | 4.813 | 5.563 | 6,25 | — | — |

| C | 1.000 | 1.250 | 1.500 | 1.750 | 2.250 | 2.500 | 3.000 | 3.625 | 4.250 | 5.000 | — | — |

| D | 0,426 | 0,560 | 0,693 | 0,859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | — | — |

| E | 1.720 | 1.688 | 1.938 | 2.000 | 2,375 | 2,375 | 3.000 | 2.938 | 3.188 | 3.750 | — | — |

| LBS | 0,89 | 1.045 | 1,955 | 3.29 | 5.34 | 7,99 | 12,73 | 18.34 | 26.36 | 37,07 | — | |

Geschmiedte Socket Weld Pipe Cap Applikatioun

ASME B16.11 Socket Weld Pipe Cap si bekannt fir aussergewéinlech Leeschtung ze liwweren a gi generell entwéckelt

fir d'Ufuerderungen ze erfëllen. Mir bidden eng breet Palette vu geschmiedte Schweissrohrkappen iwwer e weltwäit Netzwierk un

vun de Lagerhaltungsfilialen. Dëse geschmiedte Schweissrohrkapp gëtt a verschiddene Beräicher benotztBranchen wéi:

Edelstahl geschmiedte Socket-Schweissrohrkapp benotzt an Ueleg- a Gasleitungen

Geschmiedete Socket-Schweißrohrkappen an der chemescher Industrie

Benotzt fir d'Benotzung vun engem Legierungsstahl-Socket-Schweißpäifkapp an der Sanitärinstallatioun

Geschmiedte Socket Weld End Pipe Caps benotzt an der Heizung

Gebrauch vu geschmiedete Päifkappen a Waasserversuergungssystemer

ANSI B16.11 Geschmiedete Socket-Schweißpäifkapp benotzt a Kraaftwierker

Uwendungen vun der Schweißrohrkapp an der Pabeier- a Zellstoffindustrie

Geschmiedte Muffeschweissrohrkappen an allgemengen Uwendungen

Geschmiedte Socket-Schweißrohrkappen an der Fabrikatiounsindustrie

Geschmiedete Socket-Schweißrohrkappen an der Liewensmëttelindustrie

Geschmiedte Socket-Schweißrohrkappen benotzen a Strukturrohr