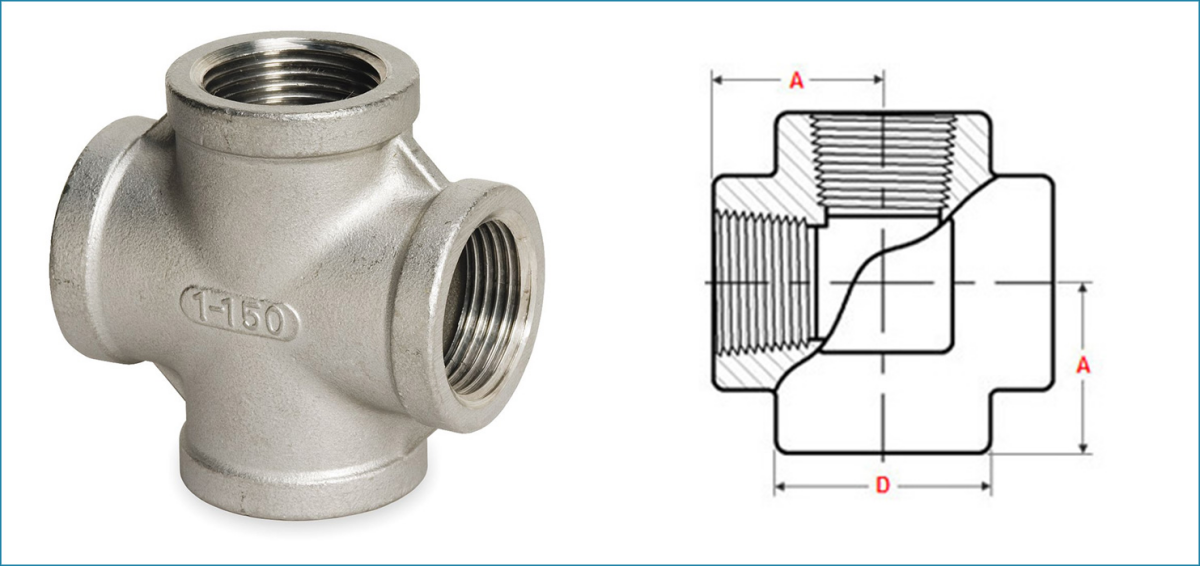

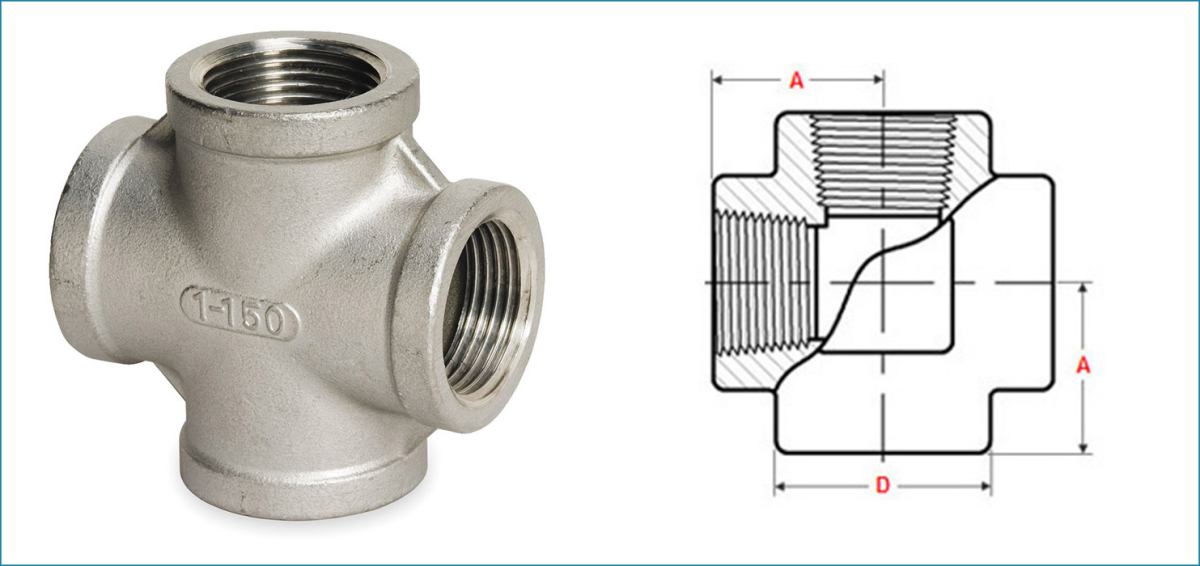

Gewinde- / geschraubte Kräiz

Liaocheng Shenghao Metal products Co., LTD. ass e féierende Produzent, Händler a Fournisseur vu Gewënn-/Schraufkräizfittingen. Et ass eng Firma, déi d'ISO-Zertifizéierung kritt huet a senge Clienten ultimativen Komfort bitt. Gewënn-/Schraufkräizfittingen maachen eng 90°-Ofzweigung vum Haaptlaf vum Päif. Si kënne benotzt ginn fir eng leckfräi an dréimomentfräi Ofdichtung an all Päif- oder Schlauchverbindung ze garantéieren. Et ass eng Fitting, déi selten an engem Päifsystem benotzt gëtt, awer trotzdem en essentiellen Deel dovun ass. E Schraufkräiz aus Edelstol gëtt et an zwou Zorten: riicht an erofsetzend. Dës Fittings hunn een Agank an dräi Ausgäng oder ëmgekéiert. ANSI B16.11 Gewënn-/Schraufkräiz, déi vun der HGFF Group Co., Ltd. produzéiert ginn, sinn no internationale Standarden entwéckelt.

ANSI/ASME B16.11 Gewënnrohrkräizstandard Spezifikatioun

| Dimensiounen | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Gréisst | 1/8″~4″ (DN6~DN100) |

| Klass | 3000 Pond, 6000 Pond, 9000 Pond |

| Typ | Muffenschweißen (S/W) & VERSCHRUFFT (SCRD) – NPT, BSP, BSPT |

| Formulaire | Gewindekräiz, Gewinderöhrekräiz, Gewindegläichkräiz |

| Wäertzousätzlech Servicer: | Waarmverzinken, Epoxy- & FBE-Beschichtung, Elektropolieren, Sandstrahlen, Gewënddrehen, Löten |

| Produktiounsqualitéiten: | Edelstahl, Legierungsstahl, Duplex, Nickellegierungen, Niddertemperaturstahl, Kuelestahl, Cupro-Nickel |

Fabrikatiounsnormen vun der Gewënnung vun engem gläiche Kräiz

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| LU: | EN10253-1, EN10253-2 |

ASME B16.11 Gewëndkräizmaterialqualitéiten

Geschmiedte Gewënnrohr aus Edelstahl:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Stol geschmiedte Gewënn gläichméisseg Kräiz:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Kuelestol geschmiedte Gewënnkräiz:

ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Geschmiedte Legierungsstahl mat Gewënn a Gläichgewiicht Kräiz:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Kupferlegierungsstahl geschmiedt Gewëndkräiz: ASTM / ASME SB 111 UNS Nr. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS Nr. C 70600 (CU-NI- 90/10), C 71500 (CU-NI- 70/30)

Nickellegierung geschmiedte Gewënn gläich Kräiz:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400 ) 02, UNS 2200 ), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

ANSI/ASME B16.11 GEWINDKREISDIMENSIOUNEN

Tabelle fir Kräizdimensioune vu Gewënnrohren

Gewindekräizdimensiounen NPS 1/2 bis 4 Klass 2000

| NPS | Min. Längt vum Fuedem | Aussenduerchmiesser vum Band D | Zentrum bis Enn A | Min. WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3,68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3,89 |

| 1.1/2 | 17,8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28,9 | 92 | 76 | 5,61 |

| 3 | 25,9 | 30,5 | 109 | 86 | 5,99 |

| 4 | 27,7 | 33 | 146 | 106 | 6,55 |

Gewinde gläichméisseg Kräiz Klass 3000 Dimensiounen NPS 1/2 bis 4

| NPS | Min. Längt vum Fuedem | Aussenduerchmiesser vum Band D | Zentrum bis Enn A | Min. WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4,98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17,8 | 18.4 | 75 | 60 | 5,56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28,9 | 102 | 83 | 7,65 |

| 3 | 25,9 | 30,5 | 121 | 95 | 8,84 |

| 4 | 27,7 | 33 | 152 | 114 | 11.18 |

Gewindekräizdimensiounen NPS 1/2 bis 4 Klass 6000

| NPS | Min. Längt vum Fuedem | Aussenduerchmiesser vum Band D | Zentrum bis Enn A | Min. WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8,53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9,93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10,59 |

| 1.1/2 | 17,8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28,9 | 121 | 95 | 15.29 |

| 3 | 25,9 | 30,5 | 146 | 106 | 16,64 |

| 4 | 27,7 | 33 | 152 | 114 | 18,67 |

D'Dimensioune sinn a Millimeter, ausser et ass anescht uginn.

D'Dimensioun B ass d'Mindestlängt vun engem perfekte Fuedem.

D'Längt vum nëtzleche Fuedem (B plus Fuedem mat voll geformte Wuerzelen a flaache Kämme) däerf net manner wéi J sinn.

ASME B16.11 Gewëndekräizgewiicht

| Klass 2000 | Nominal | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| Päif | |||||||||||||

| Gréisst | |||||||||||||

| A | – | 7/8 | 31/32 | 1 1/8 | 1. 5. 16. | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 3 | 3 3/8 | 4 3/16 | |

| B | – | 29/32 | 1 1/16 | 1. 5. 16. | 1. September 16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3. November 16 | 4 5/16 | 5 3/4 | |

| Wt | – | 0,5 | 0,46 | 0,777 | 1.125 | 1.688 | 2,45 | 3.188 | 5,56 | 16.438 | 19,5 | 32.688 | |

| Klass 3000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 7/8 | 31/32 | 1 1/8 | 1. 5. 16. | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 1/2 | |

| B | 29/32 | 1 1/16 | 1. 5. 16. | 1. September 16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| Wt | 0,438 | 0,567 | 0,97 | 1.5 | 2,5 | 3,62 | 4.125 | 6.5 | 8.125 | 16,75 | 25.675 | 32 | |

| Klass 6000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 31/32 | 1 1/8 | 1. 5. 16. | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 3/16 | 4 1/2 | |

| B | 1 1/6 | 1. 5. 16. | 1. September 16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | 6 | |

| Wt | 0,563 | 1.188 | 1.5 | 2,75 | 4.313 | 6.625 | 10,75 | 11,5 | 22.188 | 27,5 | 54 | 43,5 | |

Geschmiedte Gewënd- / Schraubung Gläichberechtegt Kräizapplikatioun

ASME B16.11 Threaded Cross ass bekannt fir aussergewéinlech Leeschtung ze liwweren a gëtt allgemeng dofir entwéckelt

erfëllt d'Ufuerderungen. Mir bidden eng breet Palette vu geschmiedte Schraufkräizer iwwer e weltwäit Netzwierk vu Lagerfilialen un. Dëst geschmiedte Gewëndkräiz gëtt a verschiddene Branchen agesat, wéi zum Beispill:

Geschmiedete Gewënnkräiz aus Edelstol a Pipeline fir Ueleg a Gas

Geschmiedte Gewëndkräizungen an der chemescher Industrie

Benotzt aus Legierungsstahl mat Gewënn gläichméissege Kräizungen an der Sanitärinstallatioun

Geschmiedte geschrauft gläichberechtegt Kräiz benotzt an der Heizung

Gewënngeschmiedete Gläichkräiz benotzt a Waasserversuergungssystemer

ANSI B16.11 Geschmiedte Gewehrkräizbenotzungen a Kraaftwierker

Uwendungen vun gläichméissege Kräizgewinde an der Pabeier- a Zellstoffindustrie

Geschmiedte geschraubte gläichméissege Kräizbenotzungen an allgemengen Uwendungen

Geschmiedte Gewëndkräizungen an der Fabrikatiounsindustrie

Geschmiedte geschrauft gläichberechtegt Kräizung benotzt an der Liewensmëttelveraarbechtungsindustrie

Geschmiedte Gewënn-Gläichkräiz-Benotzungen a Strukturrohr