Socket Weld Union

ໃນຖານະເປັນຜູ້ສົ່ງອອກ, ຜູ້ຈັດຈໍາຫນ່າຍແລະ stockist ຊັ້ນນໍາຂອງ Socket Weld Union Fittings, Liaocheng Shenghao Metal products Co., LTD. ໄດ້ພະຍາຍາມຢ່າງສອດຄ່ອງເພື່ອສະຫນອງຜະລິດຕະພັນທີ່ຫລາກຫລາຍໃຫ້ແກ່ລູກຄ້າຂອງຕົນ. ມັນເປັນບໍລິສັດທີ່ໄດ້ຮັບການຢັ້ງຢືນ ISO ທີ່ຮັບປະກັນວ່າລູກຄ້າຂອງພວກເຂົາໄດ້ຮັບຄຸນນະພາບສູງຜະລິດຕະພັນ. ສະແຕນເລດ socket Weld Unions ຖືກນໍາໃຊ້ໃນທໍ່ທີ່ມີຄວາມກົດດັນຕ່ໍາບ່ອນທີ່ມັນຈໍາເປັນຕ້ອງໄດ້ຮື້ທໍ່ເລື້ອຍໆ. A Forged Socket Weld Union ແມ່ນການອອກແບບຮ່ວມກັນ screwed. ມັນປະກອບດ້ວຍສາມຕ່ອນເຊື່ອມຕໍ່ກັນ. fitting ນີ້ມີສອງກະທູ້ພາຍໃນແລະສູນກາງທີ່ດຶງປາຍເຂົ້າກັນໃນເວລາທີ່ rotated. ເພື່ອຫຼຸດຜ່ອນການ warping ຂອງບ່ອນນັ່ງ, ສະຫະພັນຄວນໄດ້ຮັບການ screwed ແຫນ້ນກ່ອນທີ່ຈະສິ້ນສຸດແມ່ນ welded. ANSI B16.11 Socket Weld Unionfittings ແມ່ນມີຢູ່ໃນຂະຫນາດທີ່ສາມາດປັບແຕ່ງໄດ້ຕາມການຮ້ອງຂໍຂອງລູກຄ້າ. HGFF Group Co., Ltd flawlessly ຜະລິດ SocketWeld Unions ເພື່ອສະຫນອງຄວາມສະດວກສະບາຍສູງສຸດໃຫ້ແກ່ລູກຄ້າຂອງຕົນ.

ANSI/ASME B16.11 Socket Weld Union Specification ມາດຕະຖານ

| ຂະໜາດ | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| ຂະໜາດ | 1/8″ NB ຫາ 4″ NB |

| ລະດັບຄວາມກົດດັນ | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| ແບບຟອມ | Socket Weld Union, Socket Weld Pipe Union, Socket Weld Orifice Union, Forged Union, Socket Weld Union Fittings |

| ຊັ້ນຮຽນທີການຜະລິດ | ສະແຕນເລດ, ເຫຼັກໂລຫະປະສົມ, ສອງຊັ້ນ, ໂລຫະປະສົມ Nickel, ເຫລໍກອຸນຫະພູມຕ່ໍາ, ເຫຼັກກ້າຄາບອນ, Cupro Nickel |

ມາດຕະຖານການຜະລິດຂອງ Socket Weld Union Fittings

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Forged Socket Weld Union ຊັ້ນວັດສະດຸ

Nickel Alloy Forged Socket Weld Union:

ASTM / ASME SB 336, ASTM / ASME SB 564/160/163/472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400) 820 UNS , 3 ), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

ສະແຕນເລດ Forged Socket Weld Union:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F17, F319 F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld Union :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

ເຕົ້າຮັບການເຊື່ອມໂລຫະກາກບອນເຫຼັກກ້າ:

ASTM / ASME A 105, ASTM / ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld Union:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 5 CR4, 1 / CR4, 9CR, 91

Copper Alloy Steel Forged Socket Weld Union : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 45/10), C 71500 (CU -NI- 70/30)

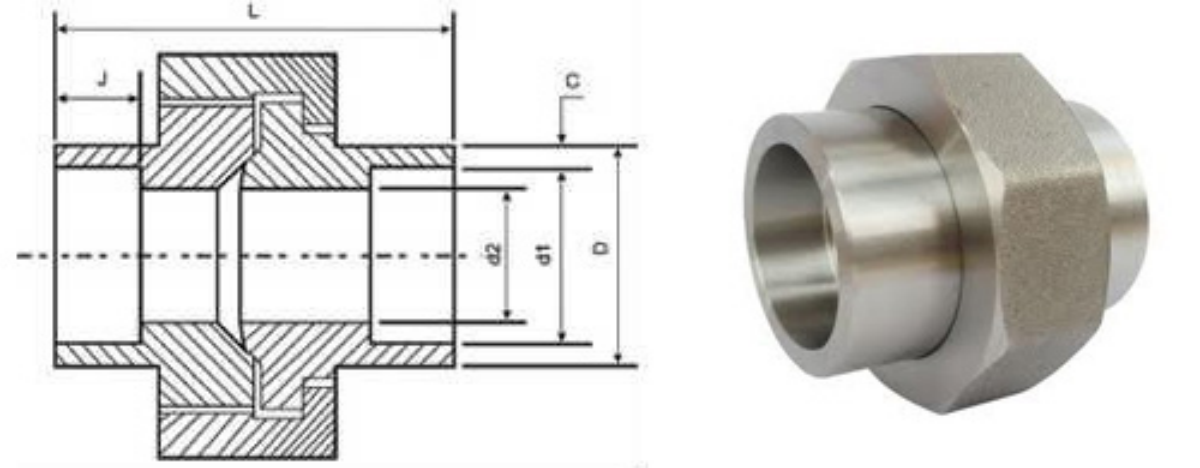

ANSI/ASME B16.11 SOCKET WELD UNION DIMENSIONS

Socket Weld Pipe Union Dimensions

| ເສັ້ນຜ່າສູນກາງນາມ | ເສັ້ນຜ່າສູນກາງນອກ | ຄວາມໜາຂອງຝາ | ເຕົ້າສຽບ | ທາງນ້ຳ | ຄວາມເລິກຂອງເຕົ້າຮັບ | ຄວາມຍາວ Assem | |||

| Dmin | Cmin | d1 | d2 | ຈິມິນ | L | ||||

| DN | NPS | ເຕົ້າຮັບ | ກະທູ້ | ເຕົ້າຮັບ | ກະທູ້ | ເຕົ້າຮັບ | ເຕົ້າຮັບ & ກະທູ້ | ເຕົ້າຮັບ | ເຕົ້າຮັບ & ກະທູ້ |

| 6 | 1/8 | 21.8 | 14.7 | 3.2 | 2.5 | 10.65 | 6.43 | 10 | 41.4 |

| 8 | 1/4 | 21.8 | 19.0 | 3.3 | 3.1 | 14.10 | 9.45 | 10 | 41.4 |

| 10 | 3/8 | 25.9 | 22.9 | 3.5 | 3.2 | 17.55 | 13.51 | 10 | 46.0 |

| 15 | 1/2 | 31.2 | 27.7 | 4.1 | 3.8 | 21.70 | 17.07 | 10 | 49.0 |

| 20 | 3/4 | 37.1 | 33.5 | 4.3 | 4.0 | 27.05 | 21.39 | 13 | 56.9 |

| 25 | 1 | 45.5 | 41.4 | 5.0 | 4.6 | 33.80 | 27.74 | 13 | 62.0 |

| 32 | 11/4 | 54.9 | 50.5 | 5.3 | 4.9 | 42.55 | 35.36 | 13 | 71.1 |

| 40 | 11/2 | 61.5 | 57.2 | 5.6 | 5.1 | 48.65 | 41.20 | 13 | 76.5 |

| 50 | 2 | 75.2 | 70.1 | 6.1 | 5.6 | 61.10 | 52.12 | 16 | 86.1 |

| 65 | 21/2 | 91.7 | 85.3 | 7.7 | 7.1 | 73.80 | 64.31 | 16 | 102.4 |

| 80 | 3 | 109.2 | 102.4 | 8.4 | 7.7 | 89.80 | 77.27 | 16 | 109.0 |

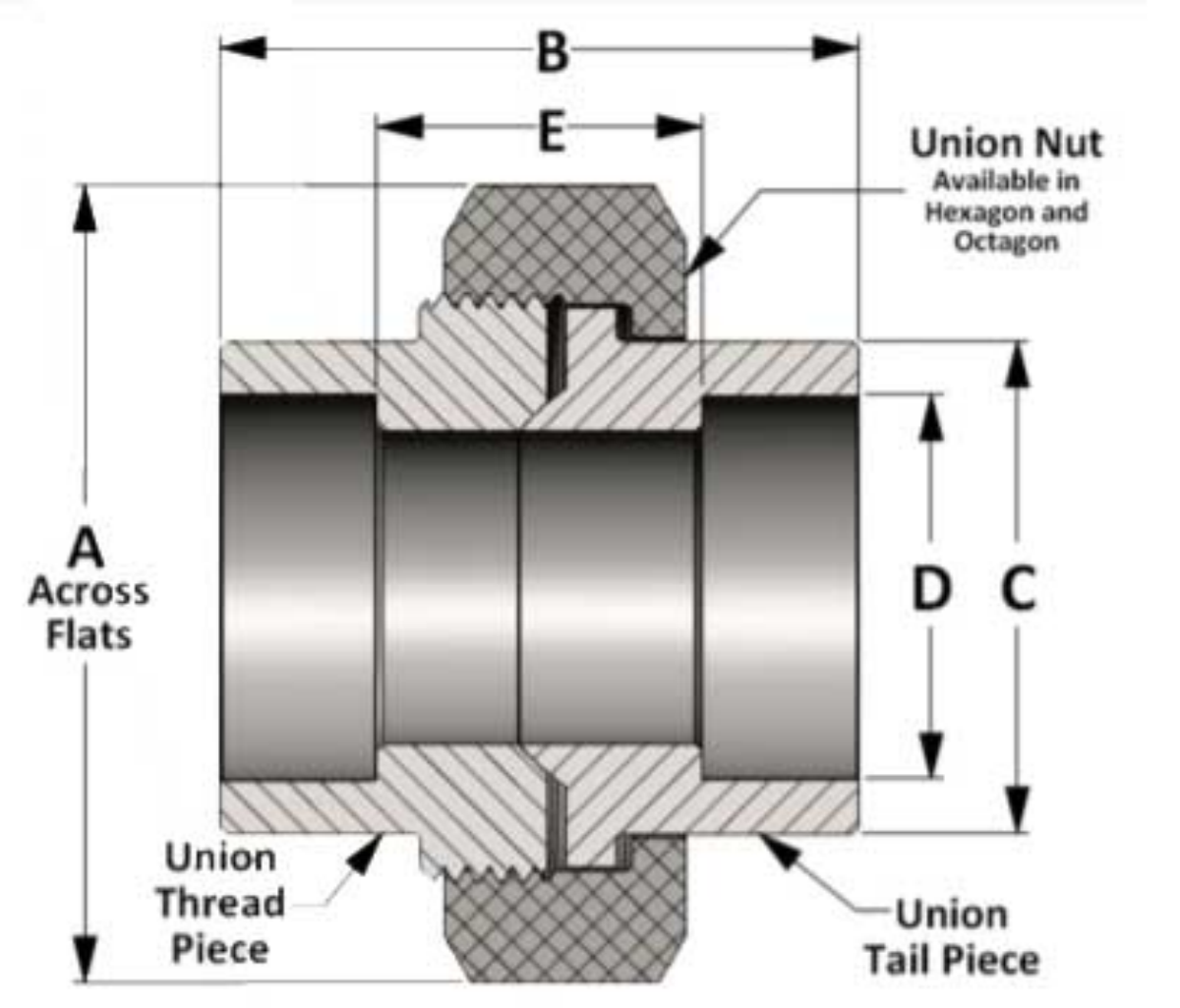

Socket Weld Union Weight2 Socket Weld Union

| CLASS 3000 Socket Weld Union | ||||||||||||

| ຂະໜາດທໍ່ | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 |

| B | 1.688 | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 |

| C | 0.865 | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | 4.545 |

| E | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 2.313 | 5.000 |

| LBS | 0.40 | 0.38 | 0.52 | 0.73 | 1.19 | 1.66 | 2.66 | 3.42 | 5.36 | 9.12 | 12.58 | 17.50 |

| CLASS 6000 Socket Weld Union | ||||||||||||

| ຂະໜາດທໍ່ | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 | — |

| B | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 | — |

| C | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 | — |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | — |

| E | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 5.750 | — |

| LBS | 0.48 | 0.56 | 0.75 | 1.35 | 2.01 | 3.17 | 3.92 | 6.60 | 10.12 | 14.00 | 40.891 | — |

| CLASS 9000 Socket Weld Union | ||||||||||||

| ຂະໜາດທໍ່ | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.750 | 2.000 | 2.250 | 2.563 | 3.063 | 3.688 | 4.313 | 5.000 | 5.750 | 6.875 | — | — |

| B | 2.500 | 2.563 | 2.938 | 3.250 | 3.750 | 4.000 | 4.625 | 4.813 | 5.563 | 6.25 | — | — |

| C | 1.000 | 1.250 | 1.500 | 1.750 | 2.250 | 2.500 | 3.000 | 3.625 | 4.250 | 5.000 | — | — |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | — | — |

| E | 1.720 | 1.688 | 1.938 | 2.000 | 2.375 | 2.375 | 3.000 | 2.938 | 3.188 | 3.750 | — | — |

| LBS | 0.89 | 1.045 | 1.955 | 3.29 | 5.34 | 7.99 | 12.73 | 18.34 | 26.36 | 37.07 | — | |

Forged Socket Weld Pipe Cap Application

ASME B16.11 Socket weld Pipe Cap ເປັນທີ່ຮູ້ກັນວ່າໃຫ້ປະສິດທິພາບພິເສດ ແລະ ໂດຍທົ່ວໄປແລ້ວໄດ້ຖືກພັດທະນາ

ເພື່ອຕອບສະຫນອງຄວາມຮຽກຮ້ອງຕ້ອງການ. ພວກເຮົາສະເຫນີໃຫ້ມີລະດັບຄວາມກ້ວາງຂອງ Forged Socket weld Pipe Cap ຜ່ານເຄືອຂ່າຍທົ່ວໂລກ

ຂອງສາຂາເກັບຮັກສາຫຼັກຊັບ. ນີ້ Forged Socket ການເຊື່ອມທໍ່ທໍ່ແມ່ນໃຊ້ໃນຕ່າງໆອຸດສາຫະກໍາເຊັ່ນ:

Stainless Steel Forged Socket weld Pipe Cap ໃຊ້ໃນທໍ່ນ້ໍາມັນແລະອາຍແກັສ

Forged Socket weld Pipe Cap ໃຊ້ໃນອຸດສາຫະກໍາເຄມີ

Alloy Steel Socket weld Pipe Cap ໃຊ້ໃນທໍ່ປະປາ

Forged Socket weld End Pipe Caps ໃຊ້ໃນການໃຫ້ຄວາມຮ້ອນ

Socket weld Forged Pipe Caps ໃຊ້ໃນລະບົບການສະຫນອງນ້ໍາ

ANSI B16.11 Forged Socket weld Pipe Cap ໃຊ້ໃນໂຮງງານໄຟຟ້າ

Socket weld Pipe Cap ໃຊ້ໃນອຸດສາຫະກໍາເຈ້ຍ & Pulp

Forged Socket weld Pipe Caps ໃຊ້ໃນການນໍາໃຊ້ຈຸດປະສົງທົ່ວໄປ

Forged Socket weld Pipe Cap ໃຊ້ໃນອຸດສາຫະກໍາ Fabrication

Forged Socket weld Pipe Cap ໃຊ້ໃນອຸດສາຫະກໍາປຸງແຕ່ງອາຫານ

Forged Socket weld Pipe Caps ໃຊ້ໃນທໍ່ໂຄງສ້າງ