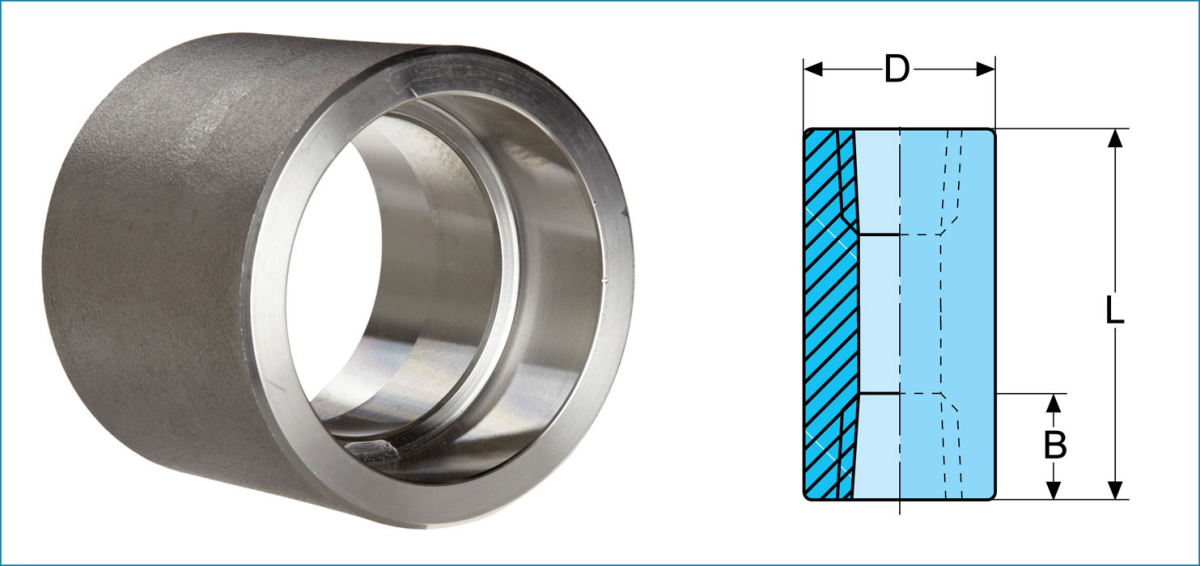

Igganċjar sħiħ tal-weldjatura tas-sokit

Bħala kumpanija ċċertifikata bl-ISO, Liaocheng Shenghao Metal products Co., LTD daħlet fis-swieq nazzjonali u internazzjonali bħala waħda mid-distributuri, fornituri u ħwienet ewlenin ta' Socket Weld Full Coupling. Socket Weld Full Couplings jintużaw biex jgħaqqdu tubi żgħar ta' dijametrupajpijiet bħala projezzjoni ta' effett ta' wweldjar fuq it-toqba tal-pajp. Iż-żewġt itruf ta' dawn l-Igganċjar Sħiħ huma bil-kamin. Huma mitluba ħafna fis-suq tat-twaħħil tal-pajpijiet. Dawn in-Nofs Igganċjar tas-Sokit tal-Azzar Inossidabbli huma ttestjati b'mod rigoruż biex jiżguraw l-ogħla kwalità ureżistenza taħt kwalunkwe kundizzjoni estrema. Dawn l-IGGANĊJAR SĦIĦ ANSI B16.11 Forged Socket Weld jintużaw f'applikazzjonijiet bħal farmaċewtiċi, bini ta' vapuri, eċċ. HGFF Group Co., Ltd. is-setgħa tagħhomklijenti l-ASME B16.11 Forged Socket Weld Full Couplings bi prezzijiet raġonevoli. Dawn huma pprovduti f'daqsijiet u ħxuna differenti għall-bżonnijiet speċifiċi tal-klijenti.

ANSI/ASME B16.11 Speċifikazzjoni Standard ta' Igganċjar Sħiħ ta' Socket Weld

Daqsijiet Sħaħ tal-Igganċjar tas-Sokit Weld

| Dimensjonijiet | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Daqs | 1/8″ NB GĦAL 4″ NB |

| Klassifikazzjonijiet tal-Pressjoni | 2000 libbra, 3000 libbra, 6000 libbra, 9000 libbra |

| Formola | Igganċjar Sħiħ, Igganċjar li Jnaqqas |

| Gradi ta' Produzzjoni | Azzar li ma jissaddadx, Azzar illigat, Duplex, Ligi tan-nikil, Azzar f'temperatura baxxa, Azzar tal-karbonju, Nikil kuprat |

Standards tal-Manifattura ta' Socket Weld Full Coupling

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Gradi ta' Materjal ta' Igganċjar Sħiħ ta' Iwweldjar tas-Sokit Falsifikat

Igganċjar sħiħ tal-weldjatura tas-sokit falsifikat tal-liga tan-nikil:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NIKEL 200), UNS 2201 (NIKEL 201), UNS 4400 (MONEL 400), UNS 2200 (NIKEL 200), UNS 2201 (NIKEL 201), UNS 4400 (MONEL 400) ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Igganċjar sħiħ tal-weldjatura tas-sokit falsifikat tal-istainless steel:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Igganċjar sħiħ tal-iwweldjar tas-sokit falsifikat tal-azzar Duplex u Super Duplex:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Igganċjar sħiħ tal-weldjatura tas-sokit falsifikat tal-azzar tal-karbonju:

ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Igganċjar sħiħ tal-weldjatura tas-sokit falsifikat tal-azzar illigat:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Igganċjar Sħiħ tal-Iwweldjar tas-Sokit Falsifikat tal-Azzar Liga tar-Ram: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU-NI- 45/10), C 71500 (CU-NI- 70/30)

ASME B16.11 Tipi Disponibbli ta' Igganċjar Sħiħ ta' Iwweldjar ta' Sokit Falsifikat ASME B16.11

| Igganċjar sħiħ tal-weldjatura tas-sokit falsifikat | Igganċjar Sħiħ tal-Iwweldjar tas-Sokit Klassi 3000 |

| Igganċjar tat-Tnaqqis tal-Weldjatura tas-Sokit | 3 4 Igganċjar Sħiħ tal-Iwweldjar tas-Sokit |

| ASME B16.11 Igganċjar tat-Tnaqqis tal-Iwweldjar tas-Sokit | Igganċjar sħiħ tal-weldjatura tas-sokit ta' 3000LB |

| ANSI B16.11 Igganċjar sħiħ tal-weldjatura tas-sokit falsifikat | Igganċjar sħiħ tal-iwweldjar tas-sokit tal-klassi 6000 |

| Piż sħiħ tal-akkoppjar tal-weldjatura tas-sokit | BS 3799 Igganċjar sħiħ tal-iwweldjar tas-sokit falsifikat |

| Tnaqqis tal-Igganċjar Sħiħ tas-Sokit Weld | Igganċjar sħiħ tal-weldjatura tas-sokit ta' kwalità għolja |

| 2 Igganċjar Sħiħ tal-Weldjatura tas-Sokit | Igganċjar sħiħ tal-weldjatura tas-sokit ta' 1/2 |

| Igganċjar sħiħ tal-weldjatura tas-sokit falsifikat ta' 3000# | Igganċjar sħiħ tal-weldjatura tas-sokit 3/4 |

| 5 Igganċjar Sħiħ tal-Weldjatura tas-Sokit | Igganċjar sħiħ tal-weldjatura tas-sokit ta' pulzier wieħed |

| 8 Igganċjar Sħiħ tal-Weldjatura tas-Sokit | Igganċjar sħiħ tal-weldjatura tas-sokit ta' 2 pulzieri |

| Igganċjar sħiħ tal-weldjatura tas-sokit ta' 6000# | Igganċjar sħiħ tal-weldjatura tas-sokit ta' 3 pulzieri |

| 6 Igganċjar Sħiħ tal-Weldjatura tas-Sokit | Igganċjar sħiħ tal-weldjatura tas-sokit ta' 6 pulzieri |

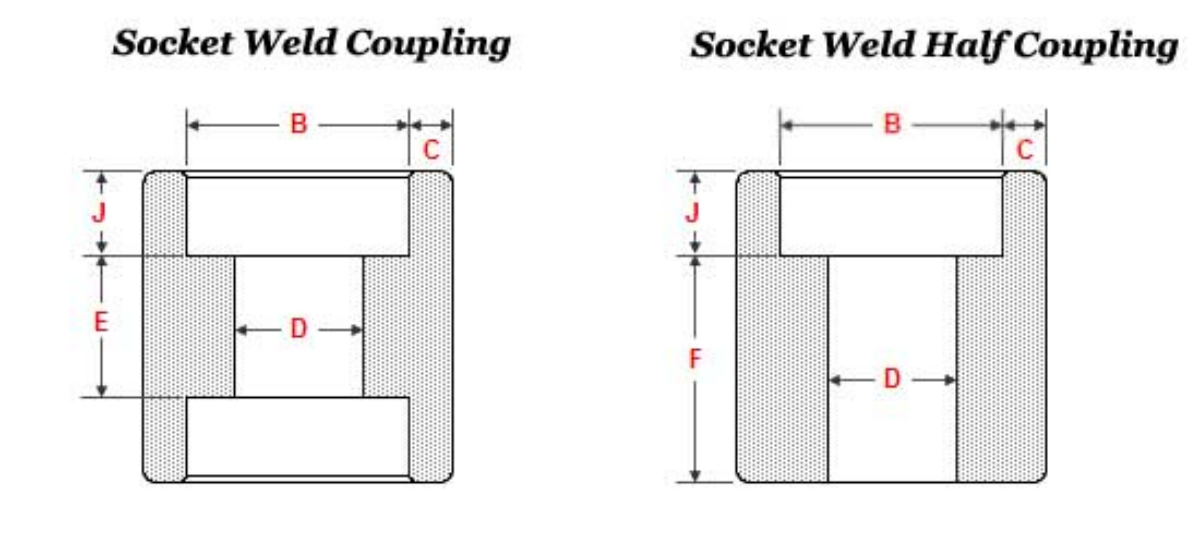

DIMENSJONIJIET SĦIĦA TA' AKKOPPJAR TA' SOCKET WELD ANSI/ASME B16.11

Dimensjonijiet tal-Igganċjar tat-Tnaqqis tal-Weldjatura tas-Sokit

Dimensjonijiet tal-Igganċjar tal-Iwweldjar tas-Sokit ta' 3000#

| NPS | Sokit Toqba | Fond Sokit | Toqba DIA | Sokit ħajt THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 | 4.65 4.10 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 | 4.90 4.25 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 | 5.70 5.00 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 | 6.05 5.30 |

| 1.1/2 | 48.90 48.65 | 13 | 41.7 40.1 | 6.35 5.55 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 | 6.95 6.05 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 | 8.75 7.65 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 | 9.50 8.30 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 | 10.70 9.35 |

| NPS | Tulijiet tat-tqegħid | |||

| Igganċjar E | Nofs akkoppjar F | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 | 47.5 | ||

Dimensjonijiet tal-Igganċjar tal-Iwweldjar tas-Sokit ta' 6000#

| NPS | Sokit | Fond | Toqba | Sokit |

| B | J | D | C | |

| 1/2 | 21.95 | 10 | 12.5 | 5.95 |

| 3/4 | 27.30 | 13 | 16.3 | 6.95 |

| 1 | 34.05 | 13 | 21.5 | 7.90 |

| 1.1/4 | 42.80 | 13 | 30.2 | 7.90 |

| 1.1/2 | 48.90 | 13 | 34.7 | 8.90 |

| 2 | 61.35 | 16 | 43.6 | 10.90 |

| NPS | Tulijiet tat-tqegħid | |||

| Igganċjar | Nofs akkoppjar | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

Id-dimensjonijiet huma f'millimetri sakemm ma jkunx indikat mod ieħor.

Toqba tas-Sokit (B) – Dimensjonijiet massimi u minimi.

Dijametru tat-Toqba (D) – Dimensjonijiet massimi u minimi.

Ħxuna tal-ħajt tas-sokit – (C) – Medja tal-ħxuna tal-ħajt tas-sokit.

It-tolleranzi dimensjonali huma ċċentrati mal-qiegħ tas-sokit – (A)

NPS 1/2 u NPS 3/4 = +/- 1.5 mm

NPS 1 sa NPS 2 = +/- 2 mm

NPS 2.1/2 sa NPS 4 = +/- 2.5 mm