Tee bil-kamin / bil-viti

Liaocheng Shenghao Metal products Co., LTD huwa manifattur akklamat ħafna tat-Tee bil-kamin ASME B16.11, li huwa reżistenti ħafna għall-korrużjoni u l-ossidazzjoni kimika (reżistenti għall-korrużjoni), u għandu xi effettività għolja ta' ksur mill-istress u rati baxxi ta' creep taħt stress għoli f'temperaturi wara trattament bis-sħana xieraq. It-Tee ugwali bil-kamin jintuża jew biex jikkombina jew jaqsam fluss ta' fluwidu. It-Tee tal-Pajp bil-kamin għandu l-istess daqsijiet tad-dħul u tal-ħruġ. Il-Fittings tat-Tee bil-kamin jintużaw f'applikazzjonijiet ta' industriji differenti bħall-ipproċessar kimiku, raffineriji taż-żejt, petrokimiki u ħafna industriji oħra. Aħna nipprovdu wkoll Tee bil-kamin falsifikat f'daqs personalizzat skont il-ħtieġa tal-klijent. Aħna nimmanifatturaw id-Dimensjonijiet tat-Te bil-kamin skont l-ASME B16.11 / BS 3799. L-istandard B16.11 ikopri l-klassifikazzjonijiet tal-pressjoni-temperatura, id-dimensjonijiet, l-immarkar, it-tolleranzi u r-rekwiżiti tal-materjal. Aħna speċjalizzati fil-provvista ta' Tee bil-kamin fi tliet klassifikazzjonijiet tal-pressjoni: klassi 2000, Klassi 3000 u 6000 bi prezz raġonevoli fiċ-Ċina. Iċċekkja t-Tabella tad-Dimensjonijiet tat-Tee tal-Pajp bil-kamin qabel tixtri.

Speċifikazzjoni Standard tat-Tee tal-Pajp bil-Kamin ANSI/ASME B16.11

| Dimensjonijiet | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Daqs | 1/8″~4″ (DN6~DN100) |

| Klassi | 3000 LBS, 6000 LBS, 9000 LBS |

| Tip | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Formola | Tee bil-kamin, Tee tal-Pajp bil-kamin, Tee Indaqs bil-kamin |

| Servizzi ta' Valur Miżjud: | Galvanizzazzjoni bis-sħana, Kisi bl-epossidu u l-FBE, Lustrar bl-elettrodu, Ibblastjar bir-ramel, Ħjut, Saldjar |

| Gradi tal-Produzzjoni: | Azzar li ma jissaddadx, Azzar illigat, Duplex, Ligi tan-nikil, Azzar f'temperatura baxxa, Azzar tal-karbonju, Nikil kuprat |

Standards tal-Manifattura ta' Tee Indaqs bil-Kamin

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Gradi ta' Materjal tat-Tee bil-Kamin ASME B16.11

Tee bil-kamin falsifikat tal-Azzar Inossidabbli:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Tee Indaqs bil-Kamin tal-Azzar Duplex u Super Duplex:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Tee bil-kamin falsifikat tal-azzar tal-karbonju:

ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

Tee Indaqs bil-Kamin Falsifikat tal-Azzar Liga:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Tee bil-kamin falsifikat tal-azzar liga tar-ram: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU-NI- 90/10), C 71500 (CU-NI- 70/30)

Liga tan-Nikil Falsifikata bil-Kamin Tee Indaqs:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NIKEL 200), UNS 2201 (NIKEL 201), UNS 4400 (MONEL 400), UNS 2200 (NIKEL 200), UNS 2201 (NIKEL 201), UNS 4400 (MONEL 400) ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

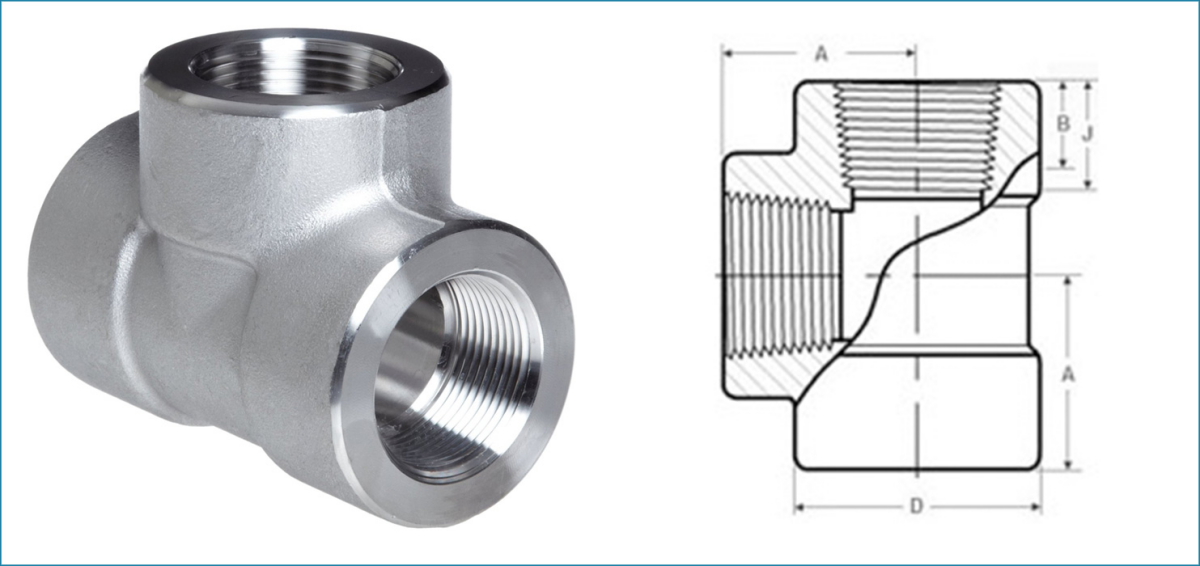

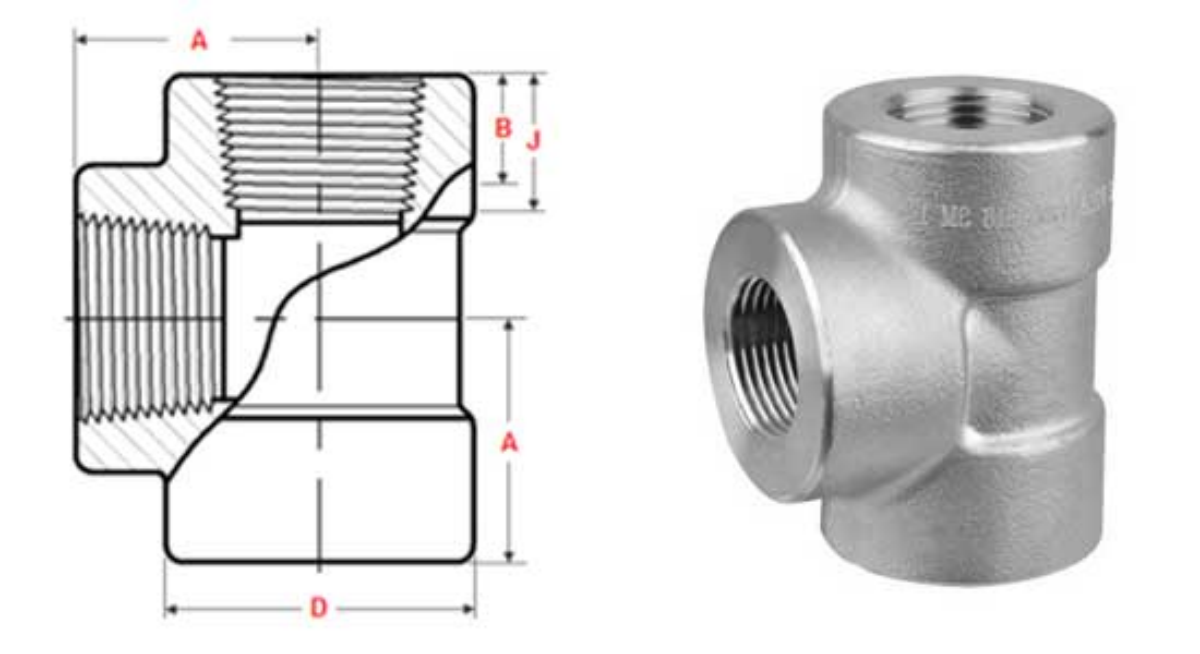

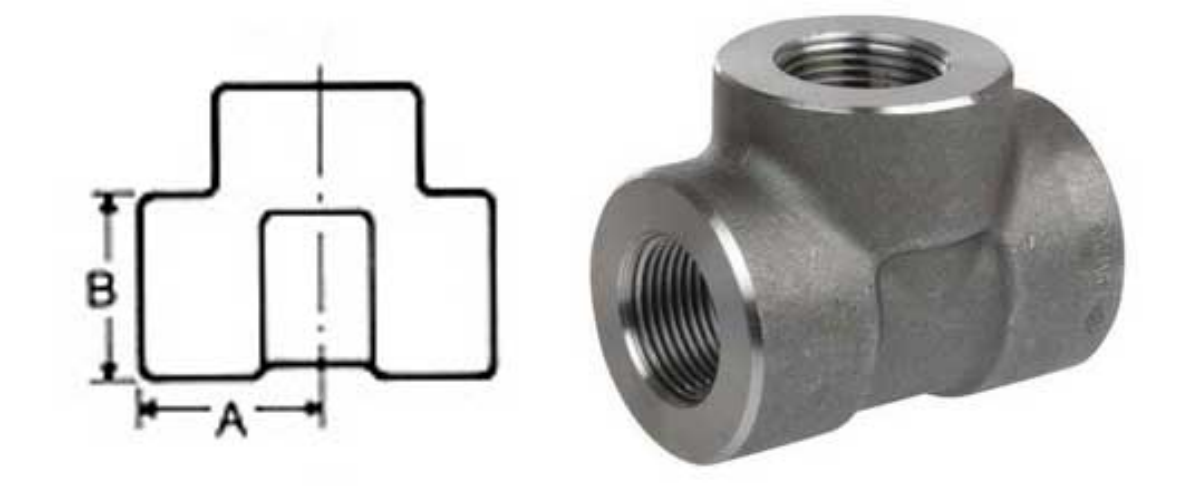

DIMENSJONIJIET TAT-TEE BIL-KAMIN ANSI/ASME B16.11

Tabella tad-Dimensjonijiet tat-Tee tal-Pajpijiet bil-Kamin

Dimensjonijiet tat-Tee bil-Kamin, Dimensjonijiet tat-Tee bil-Kamin ta' 3/4 NPS 1/2 sa 4 Klassi 2000

| NPS | Tul Minimu tal-Ħajta | Barra d-Dijametru tal-Banda D | Miċ-Ċentru sat-Tmiem A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Dimensjonijiet tat-Tee Indaqs bil-Kamin Klassi 3000 NPS 1/2 sa 4

| NPS | Tul Minimu tal-Ħajta | Barra d-Dijametru tal-Banda D | Miċ-Ċentru sat-Tmiem A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

Dimensjonijiet tat-Tee bil-Kamin 3/4 NPS 1/2 sa 4 Klassi 6000

| NPS | Tul Minimu tal-Ħajta | Barra d-Dijametru tal-Banda D | Miċ-Ċentru sat-Tmiem A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Id-dimensjonijiet huma f'millimetri sakemm ma jkunx indikat mod ieħor.

Id-dimensjoni B hija t-tul minimu tal-ħajta perfetta.

It-tul tal-ħajta utli (B flimkien mal-ħjut b'għeruq iffurmati għalkollox u qċaċet ċatti) m'għandux ikun inqas minn J.

| Klassi 2000 | Daqs Nominali tal-Pajp | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | – | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | – | 0.188 | 0.236 | 0.435 | 0.74 | 1.058 | 1.375 | 1.74 | 2.883 | 7.75 | 11.313 | 19.125 | |

|

| |||||||||||||

| Klassi 3000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.25 | 0.29 | 0.5 | 0.75 | 1.188 | 1.988 | 2.235 | 3 | 4.93 | 7.375 | 13.588 | 19.063 | |

|

| |||||||||||||

| Klassi 6000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | – | |

| F | 3月4日 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | – | |

| Wt | 0.25 | 0.64 | 0.5 | 1.438 | 2.188 | 2.785 | 4.688 | 5.75 | 9.5 | 15 | |||

Applikazzjoni Tee Indaqs bil-Kamin Falsifikat / Invitat

ASME B16.11 Threaded Tee huwa magħruf li jagħti prestazzjoni eċċezzjonali u ġeneralment huwa żviluppat għal

nilħqu t-talbiet. Noffru firxa wiesgħa ta' Tee bil-Kamin Falsifikati permezz ta' netwerk dinji ta' fergħat li jżommu l-istokk. Dan it-Tee bil-Kamin Falsifikat jintuża fidiversi industriji bħal:

Użi tat-Tee bil-Kamin Falsifikat tal-Azzar Inossidabbli fil-Pajpijiet taż-Żejt u l-Gass

Użi tat-Tee bil-Kamin Falsifikati fl-Industrija Kimika

Użi ta' Tee Indaqs bil-Ħjut tal-Azzar Liga fil-Plumbing

Użi tat-Tee Indaqs Invitati Falsifikati fit-Tisħin

Użi tat-Tee Falsifikat bil-Kamin fis-Sistemi tal-Provvista tal-Ilma

ANSI B16.11 Użi tat-Tee bil-Kamin Falsifikati fl-Impjant tal-Enerġija

Użi tat-Tee Indaqs bil-Kamin fl-Industrija tal-Karta u l-Polpa

Użi ta' Tee Indaqs Invitati Falsifikati f'Applikazzjonijiet ta' Skop Ġenerali

Użi tat-Tee bil-Kamin Falsifikati fl-Industrija tal-Fabbrikazzjoni

Użi ta' Tee Indaqs Invitati Falsifikati fl-Industrija tal-Ipproċessar tal-Ikel

Użi ta' Tee Indaqs bil-Kamin Falsifikat fil-Pajpijiet Strutturali