Flange dimension inspection: the cornerstone of precise measurement art and industrial safety

In the intricate industrial piping system, flanges, seemingly insignificant connecting components, play a crucial role. They are like joints in blood vessels, ensuring smooth fluid flow in pipelines and stable system operation. Among them, precise inspection of flange dimensions has become a key link in ensuring industrial safety and improving production efficiency.

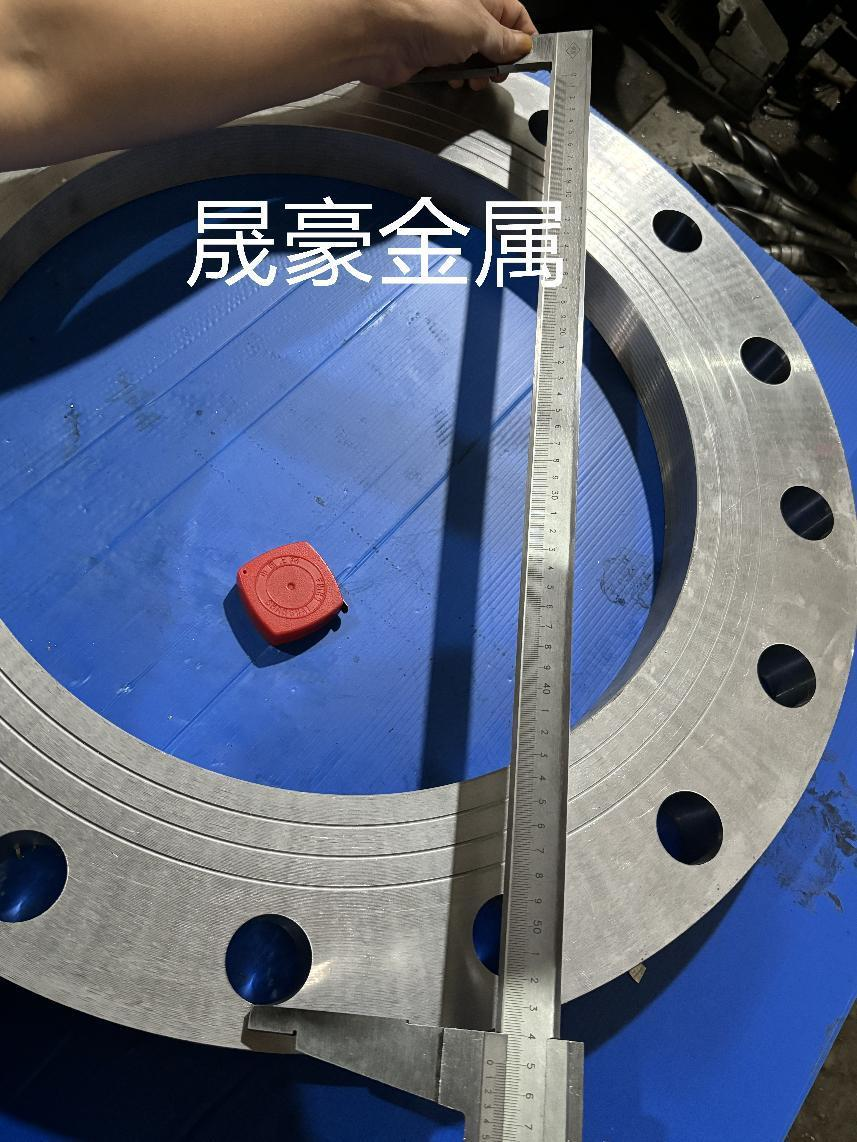

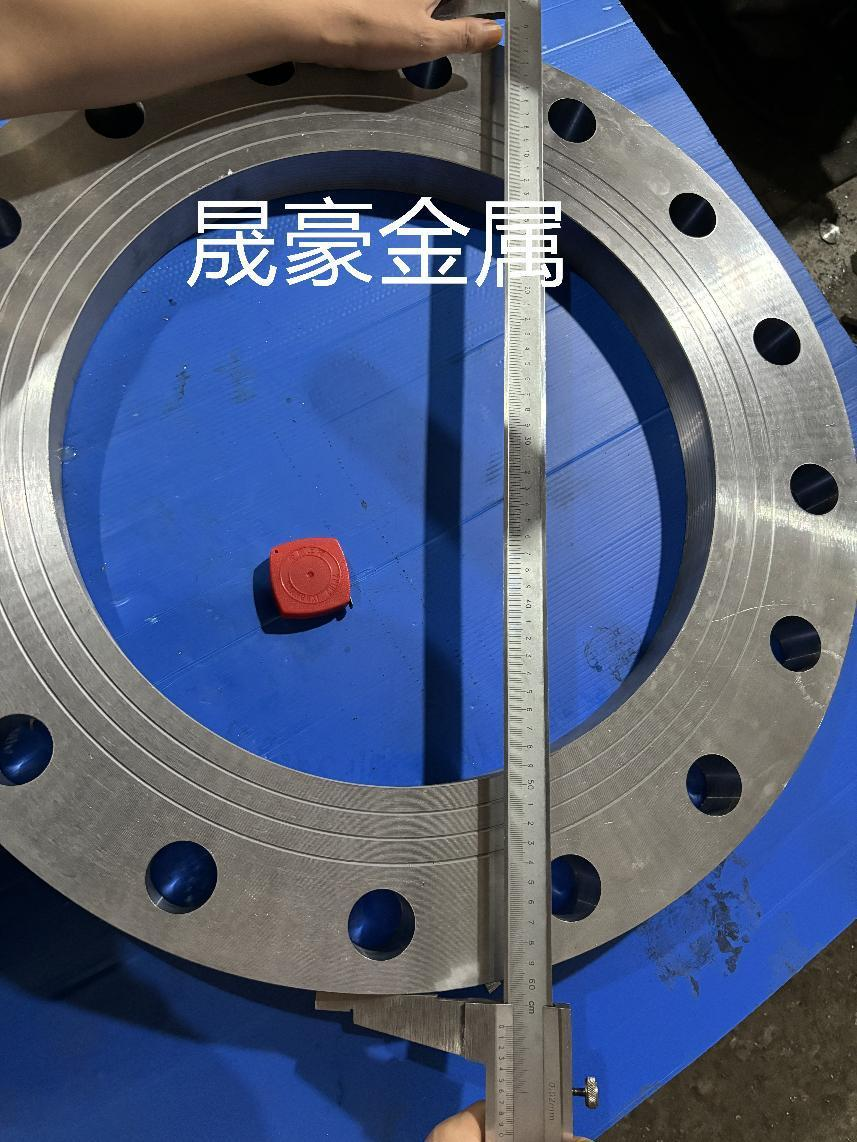

Flange dimension inspection, as the name suggests, is the meticulous measurement and verification of various dimensional parameters of flanges. From outer diameter to inner diameter, from thickness to bolt hole diameter, every data needs to be strictly measured and compared to ensure its meticulous adherence to design drawings and industry standards. This is not only a technical activity, but also an art that pursues precision.

The selection and use of measuring tools are crucial in the process of flange size inspection. Precision instruments such as vernier calipers, micrometers, and inner diameter gauges, like carving knives in the hands of craftsmen, require the skilled hands of inspectors to accurately depict the true dimensions of flanges. And every measurement is a test of the patience and meticulousness of the inspectors. Any negligence can have an immeasurable impact on subsequent installation and use.

The precise inspection of flange dimensions is of great significance for industrial safety. Sizes that are too large or too small can lead to loose connections between flanges and pipelines, resulting in serious consequences such as leaks, vibrations, and even explosions. Therefore, every flange must undergo strict dimensional inspection before leaving the factory to ensure that it can be perfectly integrated into the pipeline system and safeguard the safe operation of the industry.

In addition, flange size inspection is also an important guarantee for improving production efficiency. Accurate size matching can greatly reduce the adjustment and repair time during installation, and improve work efficiency. At the same time, it also helps to reduce rework and scrap caused by size discrepancies, lower production costs, and inject new vitality into the sustainable development of enterprises.

In summary, flange size inspection is not only a technical activity, but also an important task related to industrial safety and production efficiency. It requires inspectors to have a high sense of responsibility and professional competence, to accurately measure and rigorously control the size of each flange, and to contribute their efforts to the safe and efficient operation of the industry. In the future industrial development, we look forward to continuous innovation and progress in flange size inspection, providing a more solid guarantee for the safety and stability of industrial pipeline systems.

Post time: Sep-23-2024