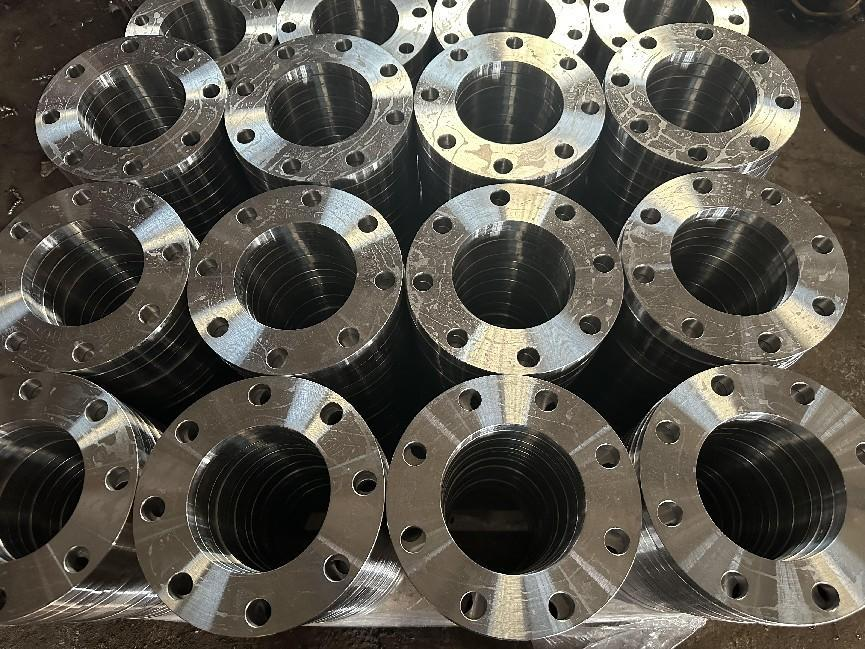

Flat welding flange (also known as flat flange or lap welding flange) is a common type of flange, mainly used to connect pipelines or equipment. Its structure is relatively simple, consisting of flanges, gaskets, and bolts and nuts. The flange plate of a flat welding flange is usually a circular or square flat plate with a certain number of bolt holes on it, used to connect with another flange or equipment through bolts.

The purpose of flat welding flanges

Pipeline connection: Flat welding flanges are widely used for connecting medium and low pressure pipelines, especially in industries such as petroleum, chemical, metallurgical, power, and construction. They can connect two sections of pipelines to form a complete fluid transport system.

Equipment connection: In addition to the connection between pipelines, flat welding flanges are also commonly used for the connection between equipment and pipelines. For example, in chemical equipment, flat welding flanges can connect the inlet and outlet pipelines of equipment such as reaction vessels and storage tanks.

Easy to install and maintain: The installation of flat welding flanges is relatively simple, just weld the flange to the pipeline, and then tightly connect the two flanges together with bolts. When it is necessary to repair or replace the pipeline, simply loosen the bolts to easily disassemble the flange for easy maintenance.

Strong adaptability: Flat welding flanges can adapt to the needs of different media, temperatures, and pressures. By selecting flanges and gaskets of different materials and thicknesses, it is possible to meet the usage requirements under various working conditions.

Advantages and disadvantages of flat welding flanges

advantage:

Convenient material selection, simple manufacturing, and relatively low cost.

Suitable for connecting medium and low pressure pipelines, widely used in various industrial fields.

Disadvantages:

Relatively poor rigidity, not suitable for high pressure, high temperature, or situations requiring high sealing performance.

In some special working conditions, such as when the medium is corrosive or flammable and explosive, it is necessary to choose flanges and gaskets made of special materials.

In summary, flat welding flanges are an economical and practical pipeline connection component widely used in various industrial fields. However, when selecting and using, it is necessary to make reasonable choices and configurations based on specific working conditions and requirements.

Post time: Aug-15-2024