Tee Wopangidwa ndi Ulusi

Liaocheng Shenghao Metal products Co., LTD ndi opanga odziwika kwambiri a ASME B16.11 Threaded Tee, omwe amalimbana kwambiri ndi dzimbiri ndi ma oxidation amankhwala (kusamva dzimbiri), ndipo amakhala ndi kupsinjika kwambiri komanso kutsika kotsika pansi pa kupsinjika kwakukulu pakutentha pambuyo pa chithandizo choyenera cha kutentha. Threaded Equal Tee imagwiritsidwa ntchito kuphatikiza kapena kugawa madzimadzi. Threaded Pipe Tee ili ndi kukula kolowera komweko komanso kotulutsa. Ma Threaded Tee Fittings amagwiritsidwa ntchito m'mafakitale osiyanasiyana monga kukonza mankhwala, kukonza mafuta, petrochemical ndi mafakitale ena ambiri. Timaperekanso Forged Threaded Tee mukukula makonda malinga ndi zomwe kasitomala amafuna. Timapanga Threaded Tee Dimensions molingana ndi ASME B16.11 / BS 3799. Muyezo wa B16.11 umakhudza kupanikizika-kutentha, miyeso, chizindikiro, kulolerana ndi zofunikira zakuthupi. Ndife apadera popereka Threaded Tee m'magawo atatu okakamiza: kalasi 2000, Class 3000 ndi 6000 pamtengo wokwanira ku China. Yang'anani Tchati cha Threaded Pipe Tee Dimensions musanagule.

ANSI/ASME B16.11 Matchulidwe Okhazikika a Pipe Tee

| Makulidwe | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Kukula | 1/8″~4″ (DN6~DN100) |

| Kalasi | 3000 LBS, 6000 LBS, 9000 LBS |

| Mtundu | Socket Weld (S/W) & SCREWED (SCRD) - NPT, BSP, BSPT |

| Fomu | Tee Wopangidwa ndi Ulusi, Tee Wachitoliro Waulusi, Tee Wofanana Wofanana |

| Ntchito Zowonjezera Mtengo: | Mafuta Oviikidwa Otentha, Epoxy & FBE Coating, Electro Polish, Kuphulika kwa Mchenga, Kuwombera, Kuwotcha |

| Magiredi Opanga: | Chitsulo chosapanga dzimbiri, Chitsulo cha Aloyi, Duplex, Nickel Alloys, Chitsulo chotsika, Chitsulo cha Carbon, Nickel ya Cupro |

Kupanga Miyezo ya Threaded Equal Tee

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Maphunziro a Tee Material

Tee Yopangidwa Ndi Zitsulo Zosapanga dzimbiri :

F304 ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321, F19, F19, F19 F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Threaded Equal Tee:

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Tee ya Carbon Steel Forged Threaded Tee:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Tee ya Alloy Steel Forged Threaded Equal Tee :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, CR, CR, CR, CR 91

Tee ya Copper Alloy Forged Threaded Tee : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

Tee ya Nickel Alloy Forged Threaded Equal Tee:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 200 ( ALLO 200 ) UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

ANSI/ASME B16.11 MIZINDIKIRO YA TEE

Tchati cha Makulidwe a Pipe Tee

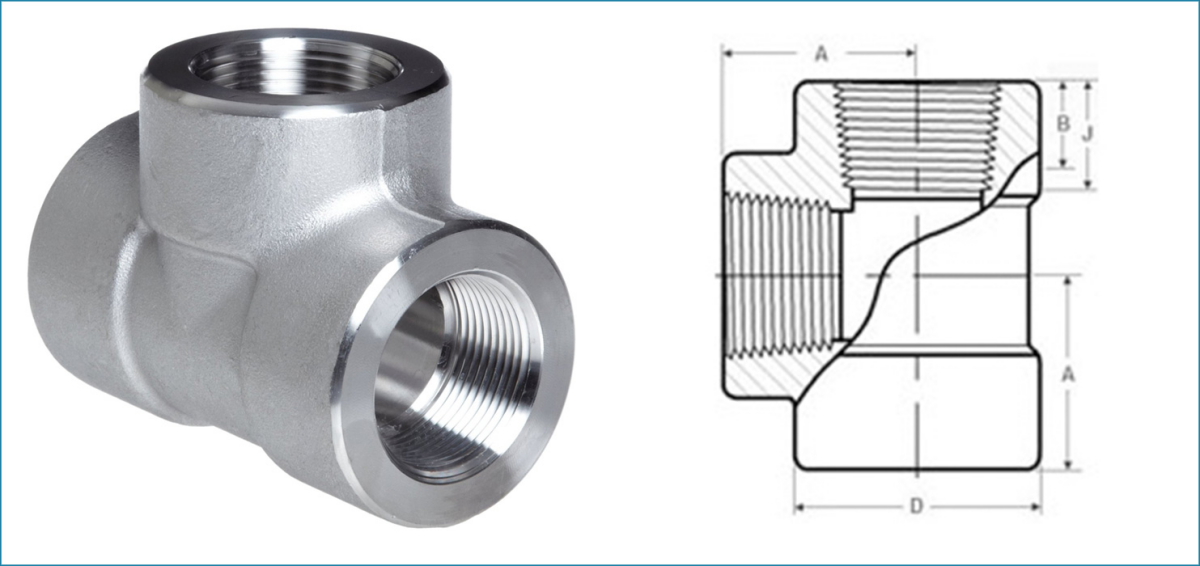

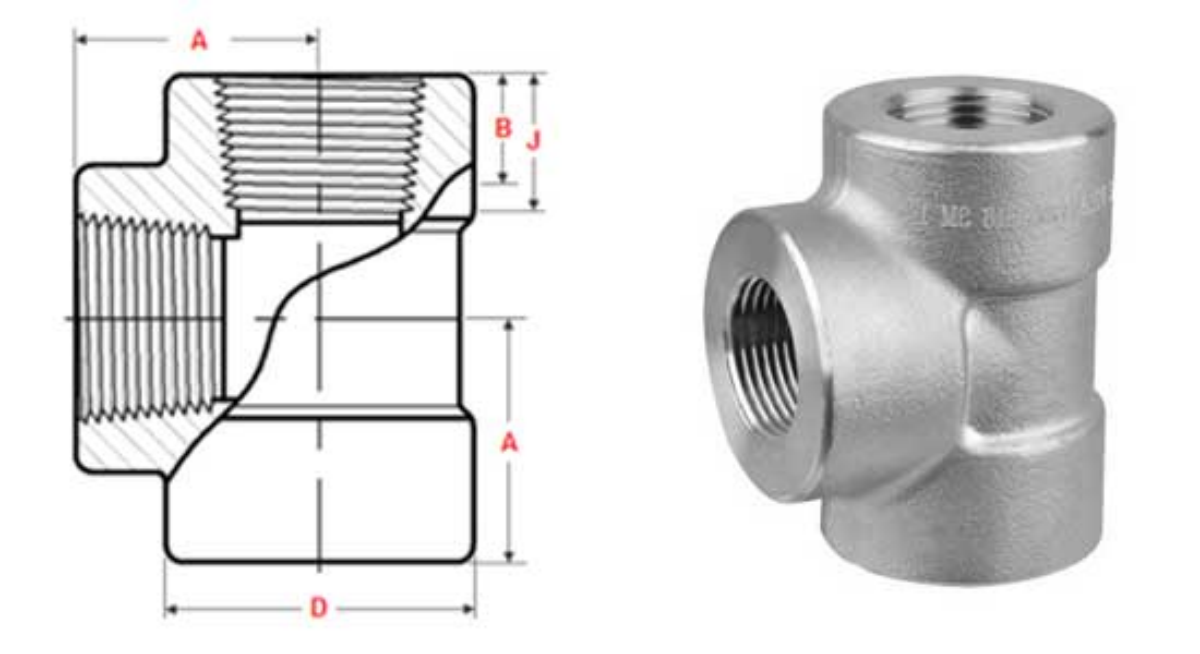

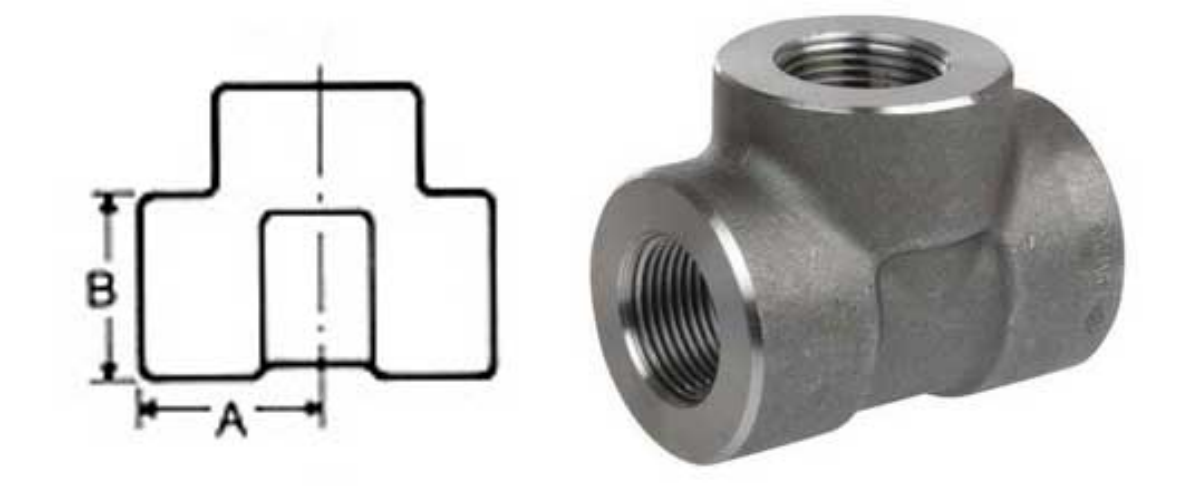

Makulidwe a Tee Opangidwa ndi Ulusi, Makulidwe a Tee 3/4 NPS 1/2 mpaka 4 Kalasi 2000

| NPS | Min Length of Thread | Kunja kwa Dia wa Band D | Center mpaka Mapeto A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Miyeso Yofanana ya Tee Class 3000 Dimensions NPS 1/2 mpaka 4

| NPS | Min Length of Thread | Kunja kwa Dia wa Band D | Center mpaka Mapeto A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

3/4 Miyezo ya Tee Yopangidwa ndi NPS 1/2 mpaka 4 Kalasi 6000

| NPS | Min Length of Thread | Kunja kwa Dia wa Band D | Center mpaka Mapeto A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Miyeso ili mu millimeters pokhapokha ngati tasonyezedwa.

Dimension B ndi kutalika kwa ulusi wabwino kwambiri.

Utali wa ulusi wothandiza (B kuphatikiza ulusi wokhala ndi mizu yokhazikika bwino) usakhale wotsika kuposa J.

| Gawo la 2000 | Kukula Kwapaipi Kwadzina | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | - | 29/32 | 1 1/16 | 15/16 | 19/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | - | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 15/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | - | 0.188 | 0.236 | 0.435 | 0.74 | 1.058 | 1.375 | 1.74 | 2.883 | 7.75 | 11.313 | 19.125 | |

|

| |||||||||||||

| Gawo la 3000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 29/32 | 1 1/16 | 15/16 | 19/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 15/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.25 | 0.29 | 0.5 | 0.75 | 1.188 | 1.988 | 2.235 | 3 | 4.93 | 7.375 | 13.588 | 19.063 | |

|

| |||||||||||||

| Gawo la 6000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 1 1/6 | 15/16 | 19/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | - | |

| F | 3 月4 tsiku | 1 | 1 1/8 | 1 1/4 | 15/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | - | |

| Wt | 0.25 | 0.64 | 0.5 | 1.438 | 2.188 | 2.785 | 4.688 | 5.75 | 9.5 | 15 | |||

Forged Threaded / Screwed Equal Tee Application

ASME B16.11 Threaded Tee imadziwika kuti imapereka magwiridwe antchito apadera ndipo nthawi zambiri imapangidwira

kukwaniritsa zofuna. Timapereka mitundu yambiri ya Forged Screwed Tee kudzera pagulu lapadziko lonse la nthambi zosunga masheya. Izi Forged Threaded Tee imagwiritsidwa ntchitomafakitale osiyanasiyana monga:

Stainless Steel Forged Threaded Tee amagwiritsa ntchito Paipi ya Mafuta ndi Gasi

Forged Threaded Tee amagwiritsa ntchito Chemical Viwanda

Alloy Steel Threaded Equal Tee amagwiritsa ntchito Plumbing

Forged Screwed Equal Tee amagwiritsa ntchito Kutentha

Threaded Forged Tee amagwiritsa ntchito Water Supply Systems

ANSI B16.11 Forged Threaded Tee amagwiritsa ntchito Power Plant

Ma Threaded Equal Tee amagwiritsa ntchito Paper & Pulp Viwanda

Forged Screwed Equal Tee amagwiritsa ntchito General Purpose Applications

Forged Threaded Tee amagwiritsa ntchito mu Fabrication Viwanda

Forged Screwed Equal Tee amagwiritsa ntchito Food Processing Viwanda

Forged Threaded Equal Tee amagwiritsa ntchito mu Structural Pipe