Threaded / Screwed Tee

Liaocheng Shenghao Metal products Co., LTD mugadziri ane mukurumbira mukuru weASME B16.11 Threaded Tee, iyo inoshingirira zvakanyanya kumakemikari ekuora uye oxidation (inodzivirira kupisa), uye ine kumwe kushushikana kwakanyanya-kuputika kwekuita uye kuderera kwemazinga pasi pekunetseka kwakanyanya pakupisa mushure mekurapa kwakakodzera kwekupisa. Threaded Equal Tee inogona kushandiswa kusanganisa kana kupatsanura kuyerera kwemvura. Threaded Pipe Tee ine yakafanana inlet uye outlet saizi. Threaded Tee Fittings anoshandiswa mumaindasitiri akasiyana mafomu senge makemikari kugadzirisa, mafuta ekunatsa, petrochemical uye mamwe akawanda maindasitiri. Isu tinopawo Forged Threaded Tee muhukuru hwakajairwa sekuenderana nezvinodiwa nemutengi. Isu tinogadzira Threaded Tee Dimensions zvinoenderana neASME B16.11 / BS 3799. Iyo B16.11 chiyero inovhara kudzvanywa-tembiricha zviyero, zviyero, kutara, kushivirira uye zvinhu zvinodiwa. Isu takasarudzika mukugovera Threaded Tee mumatatu ekumanikidza ratings: kirasi 2000, Kirasi 3000 uye 6000 nemutengo unonzwisisika muChina. Tarisa Threaded Pipe Tee Dimensions Chati usati watenga.

ANSI/ASME B16.11 Threaded Pipe Tee Standard Specification

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/8″~4″ (DN6~DN100) |

| Kirasi | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socket Weld (S/W) & SCREWED (SCRD) - NPT, BSP, BSPT |

| Form | Tee ine Threaded, Threaded Pipe Tee, Threaded Equal Tee |

| Value Added Services: | Kupisa Kwakanyikwa Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Magiredhi ekugadzira: | Stainless Simbi, Alloy Steel, Duplex, Nickel Alloys, Yakadzika tembiricha Simbi, Carbon Steel, Cupro Nickel |

Manufacturing Standards yeThreaded Equal Tee

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Threaded Tee Material Grades

Stainless Steel Forged Threaded Tee:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321, F11, F311, F316 F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Threaded Equal Tee:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Threaded Tee:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Threaded Equal Tee :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, CR, CR, CR 91

Copper Alloy Steel Forged Threaded Tee : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

Nickel Alloy Forged Threaded Equal Tee:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 3 CB / 200 ALLO 80 UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

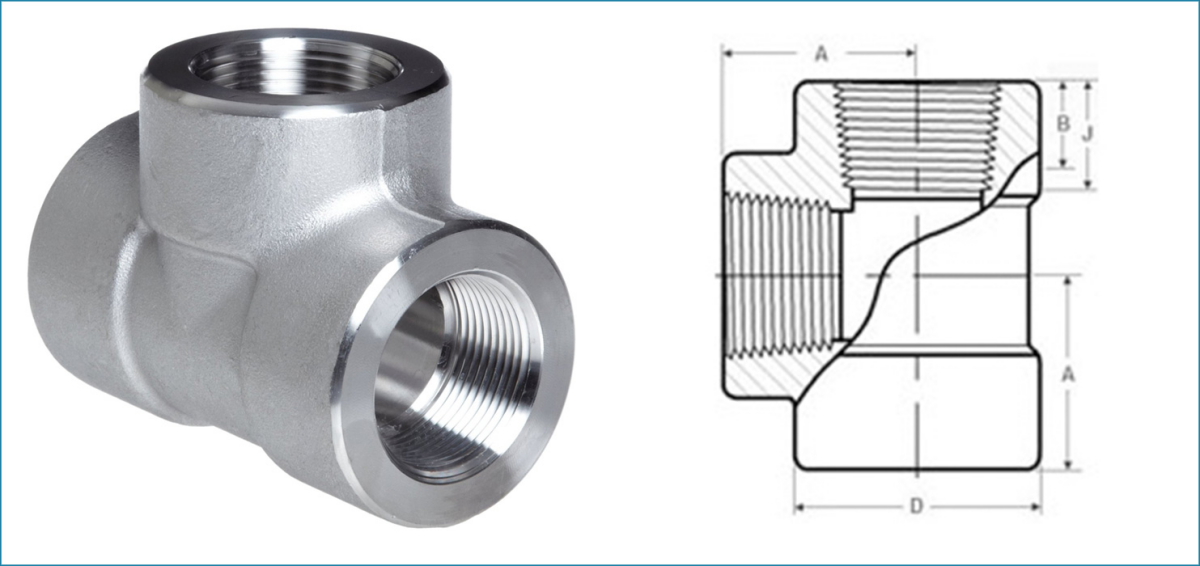

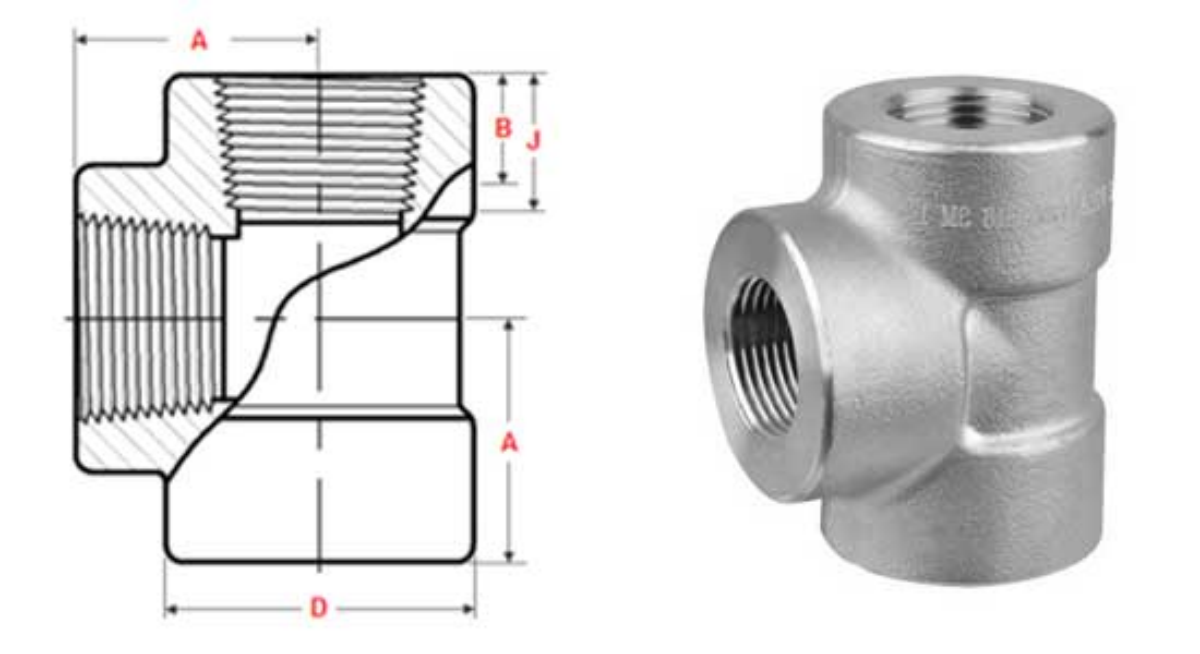

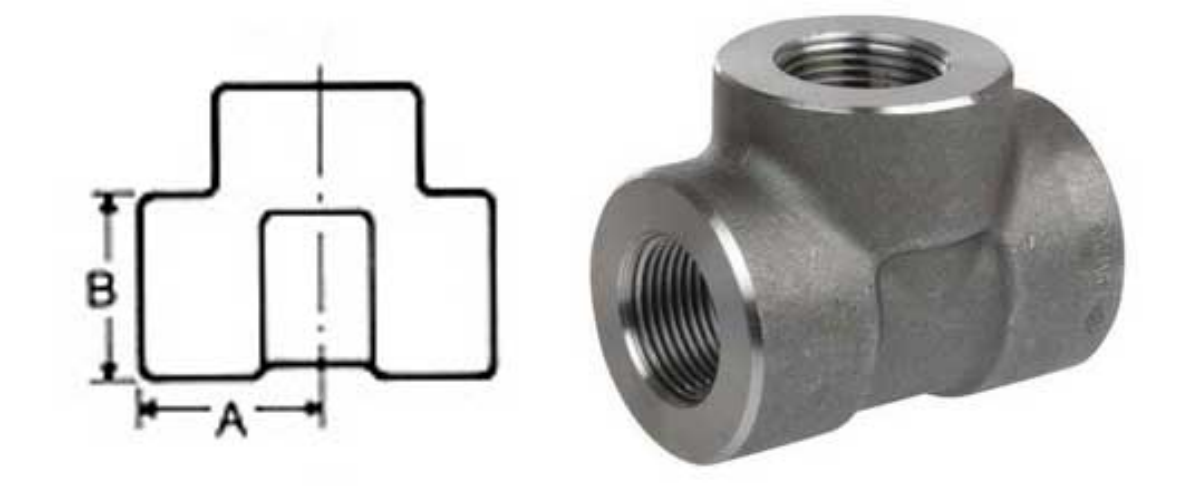

ANSI/ASME B16.11 TEE DIMENSIONS INE THREADED

Threaded Pipe Tee Dimensions Chart

Yakarukwa Tee Dimensions, 3/4 Yakarukwa Tee Dimensions NPS 1/2 kusvika 4 Kirasi 2000

| NPS | Min Length of Thread | Kunze Dia yeBand D | Center to End A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Yakarukwa Yakaenzana Tee Kirasi 3000 Dimensions NPS 1/2 kusvika 4

| NPS | Min Length of Thread | Kunze Dia yeBand D | Center to End A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

3/4 Yakarukwa Tee Dimensions NPS 1/2 kusvika 4 Kirasi 6000

| NPS | Min Length of Thread | Kunze Dia yeBand D | Center to End A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Zviyero zviri mumamilimita kunze kwekunge zvaratidzwa.

Dimension B hurefu hudiki hweshinda yakakwana.

Hurefu hweshinda inobatsira (B pamwe neshinda dzine midzi yakanyatsogadzirwa uye makrete akatsetseka) haizove shoma pane J.

| Kirasi 2000 | Nominal Pipe Size | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | - | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| F | - | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | - | 0.188 | 0.236 | 0.435 | 0.74 | 1.058 | 1.375 | 1.74 | 2.883 | 7.75 | 11.313 | 19.125 | |

|

| |||||||||||||

| Kirasi 3000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| F | 3/4 | 3/4 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | |

| Wt | 0.25 | 0.29 | 0.5 | 0.75 | 1.188 | 1.988 | 2.235 | 3 | 4.93 | 7.375 | 13.588 | 19.063 | |

|

| |||||||||||||

| Kirasi 6000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | - | |

| F | 3月4日 | 1 | 1 1/8 | 1 1/4 | 1 5/16 | 1 3/8 | 1 11/16 | 1 3/4 | 2 1/16 | 2 1/2 | 3 1/8 | - | |

| Wt | 0.25 | 0.64 | 0.5 | 1.438 | 2.188 | 2.785 | 4.688 | 5.75 | 9.5 | 15 | |||

Forged Threaded / Screwed Equal Tee Application

ASME B16.11 Threaded Tee inozivikanwa kuunza mashandiro emhando yepamusoro uye inowanzogadzirirwa

kuita zvinodiwa. Isu tinopa huwandu hwakawanda hweForged Screwed Tee kuburikidza netiweki yepasi rose yemapazi ekuchengetedza masheya. Iyi Forged Threaded Tee inoshandiswa mukatimaindasitiri akasiyana se:

Stainless Steel Forged Threaded Tee inoshandisa muOiri neGasi Pipeline

Forged Threaded Tee inoshandisa muChemical Indasitiri

Alloy Steel Yakarukwa Yakaenzana Tee inoshandisa muPlumbing

Forged Screwed Equal Tee inoshandisa mukupisa

Threaded Forged Tee inoshandisa muMvura Supply Systems

ANSI B16.11 Forged Threaded Tee inoshandisa muSimba reSimba

Threaded Equal Tee inoshandisa muPepa & Pulp Indasitiri

Forged Screwed Equal Tee inoshandisa muGeneral Purpose Application

Forged Threaded Tee inoshandisa muFabrication Indasitiri

Forged Screwed Equal Tee inoshandisa muIndasitiri Yekugadzira Chikafu

Forged Threaded Equal Tee inoshandisa muStructural Pipe