Xadhkaha goostay 45/90 Deg Suxulka

Kobcinta suuqyada qaranka iyo kuwa caalamiga ah, Liaocheng Shenghao Metal Product Co., LTD waxay ilaalinaysaa sumcaddeeda soo-saare-dhamaadka sare, alaab-qeybiyaha iyo dhoofiyaha Xarkaha / Xargaha 90 °. Ku habboonaantani waxay ka dhigaysaa 90° beddelka jihada socodka tuubada. Waxay ku darsataa lumitaanka cadaadiska nidaamka sababtoo ah khilaaf, saameyn iyo dib-u-dardargelin. Qalabyada Suxulka ee 90° ee Xargaha Dahsoon birta Aan Lahayn waxay siisaa isku xidhka alxanka weligeed ah ee codsiyada daruuriga ah sida dhuumaha sahayda biyaha iyo hababka kale ee wareejinta dareeraha. Waayo, ANSI B16.11 Been abuurtay 90 Suxulada, darafyadiisa dunsan 90 Deg Suxulka, SS 90 deg. Suxulka dunta leh, 90 digrii suxulka la been abuurtay ayaa lagu farsamayn karaa ama la goyn karaa. Qalabkan waxa loo soo saaray laba nooc; xusullada radius gaaban iyo xusullada raadiyaha dheer. HGFF Group Co., Ltd. waa soo-saare hal-abuur leh iyo kaydiye ASME B16.11 Xarig-gaaban/Xukun 90° ah. Waxay u fidiyaan adeegyada macaamiisha marka ay u socdaan waxayna sameeyaan dadaal joogto ah si ay macaamiishu ugu qancaan

ANSI/ASME B16.11 Xarigsan 90 Degree Cadaynta Suxulka

| Cabirka | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Cabbirka | 1/8 "~ 4" (DN6 ~ DN100) |

| Fasalka | 3000 LBS, 6000 LBS, 9000 LBS |

| Nooca | Socket Weld (S/W) & SCREWED (SCRD) - NPT, BSP, BSPT |

| Foomka | 90 Deg Suxulka Xadhkaha Leh,Xusul Xadhkaha Leh,Xulka Tubta Xadhkaha Leh |

| Adeegyada Lagu Daray Qiimaha: | Galvanizing Kulul, Dahaarka Epoxy & FBE, Polish Electro, Bacaad Qarxaysa, Xadhkaha, Alxanka |

| Darajooyinka wax soo saarka: | Birta Aan Lahayn, Birta Daawaha ah, Duplex, Nikel Alloys, Birta Heerkulka Hoose, Birta Kaarboonka, Cupro Nickel |

Heerarka Wax soo saarka ee Xadhkaha 90 Degga ah

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| E: | EN10253-1, EN10253-2 |

Darajooyinka Qalabka Xadhkaha Leh

Bir Aan-Aan Lahayn Oo La Been Abuuray Xadhkaha 90 Degga Ah:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F191H, F321H F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Been Abuurka ah ee 90 Deg Xusul:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Birta Kaarboonka ee Been Abuurka ah ee Xadhkaha Leh 90 Degmo:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Aloy Steel Been Abuurka Xadhkaha 90 Degga ah:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 CR2/1 CR, 91

Birta Daawaha ee Copper Forged Xarig 90 Deg ah xusul: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10), C 71500 (CU -NI- 70/30)

Nickel Alloy Been Abuurka Xadhkaha 90 Degga ah:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201) UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601) UNS 6625 (INCONEL 625) UNS 10276 (HASTELLOY C 276)

ANSI/ASME B16.11 qeeybyada xusulka dunta leh

| Fasalka 2000 | Magac ahaan | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| A | - | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 3 | 3 3/8 | 4 3/16 | |

| B | - | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| Wt | - | 0.198 | 0.283 | 0.500 | 0.773 | 1.013 | 1.550 | 2.180 | 3.140 | 6.500 | 10.925 | 26.675 | |

|

| |||||||||||||

| Fasalka 3000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| A | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 1/2 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| Wt | 0.236 | 0.350 | 0.592 | 0.973 | 1.355 | 2.265 | 2.407 | 3.500 | 5.920 | 11.900 | 14.438 | 31.975 | |

|

| |||||||||||||

| Fasalka 6000 |

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| A | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 3/16 | 4 1/2 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | 6 | |

| Wt | 0.250 | 0.625 | 1.023 | 1.625 | 2.625 | 3.500 | 6.750 | 7.500 | 13.438 | 20.875 | 39.050 | 38.000 | |

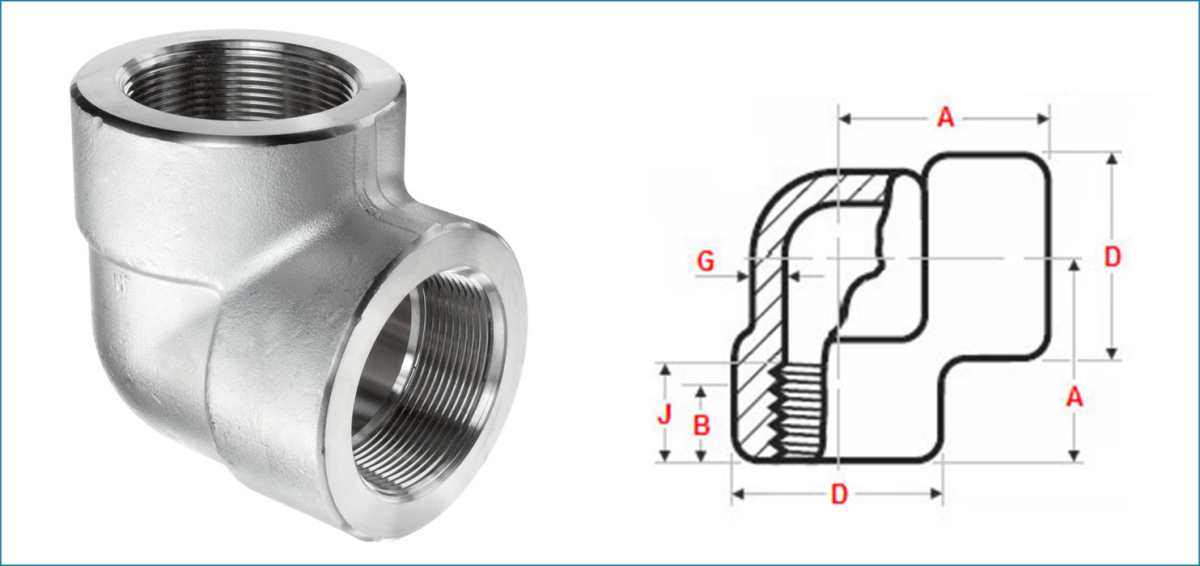

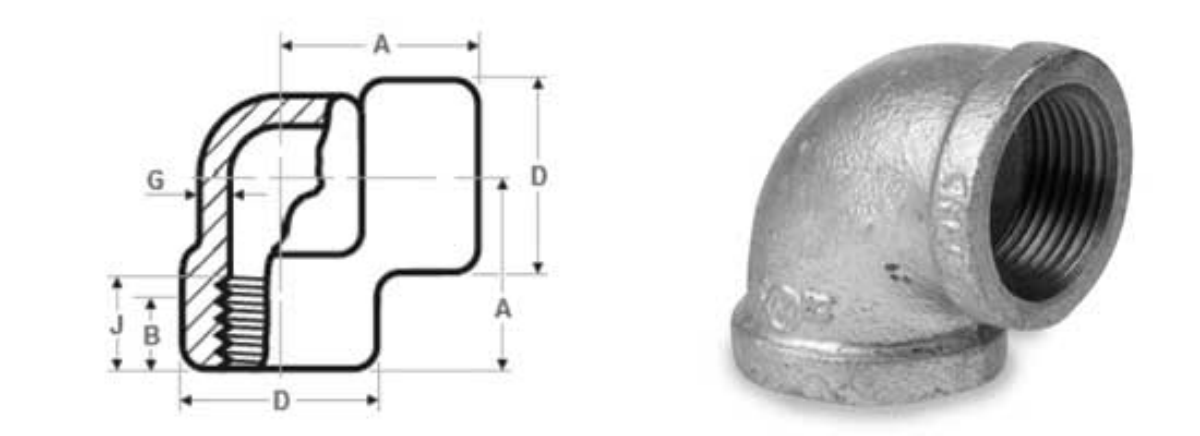

Xajmiga 90 cabbirka xusulka, cabbirka xusulka dunta 90 darajo

Cabbirrada xusulka dunsan NPS 1/2 ilaa 4 Fasalka 2000

| NPS | Dhererka min of Thread | Dibadda Dia ee Band | Min WT | Xarun ilaa Dhamaad | ||

| B | J | D | G | 90° A | 45° C | |

| 1/2 | 10.9 | 13.6 | 33 | 3.18 | 28 | 22 |

| 3/4 | 12.7 | 13.9 | 38 | 3.18 | 33 | 25 |

| 1 | 14.7 | 17.3 | 46 | 3.68 | 38 | 28 |

| 1.1/4 | 17 | 18 | 56 | 3.89 | 44 | 33 |

| 1.1/2 | 17.8 | 18.4 | 62 | 4.01 | 51 | 35 |

| 2 | 19 | 19.2 | 75 | 4.27 | 60 | 43 |

| 2.1/2 | 23.6 | 28.9 | 92 | 5.61 | 76 | 52 |

| 3 | 25.9 | 30.5 | 109 | 5.99 | 86 | 64 |

| 4 | 27.7 | 33 | 146 | 6.55 | 106 | 79 |

Heerka xusulka 3000 Cabbirrada NPS 1/2 ilaa 4

| NPS | Dhererka min of Thread | Dibadda Dia ee Band | Min WT | Xarun ilaa Dhamaad | ||

| B | J | D | G | 90° A | 45° C | |

| 1/2 | 10.9 | 13.6 | 38 | 4.09 | 33 | 25 |

| 3/4 | 12.7 | 13.9 | 46 | 4.32 | 38 | 28 |

| 1 | 14.7 | 17.3 | 56 | 4.98 | 44 | 33 |

| 1.1/4 | 17 | 18 | 62 | 5.28 | 51 | 35 |

| 1.1/2 | 17.8 | 18.4 | 75 | 5.56 | 60 | 43 |

| 2 | 19 | 19.2 | 84 | 7.14 | 64 | 44 |

| 2.1/2 | 23.6 | 28.9 | 102 | 7.65 | 83 | 52 |

| 3 | 25.9 | 30.5 | 121 | 8.84 | 95 | 64 |

| 4 | 27.7 | 33 | 152 | 11.18 | 114 | 79 |

Cabbirrada xusulka dunsan ee lab NPS 1/2 ilaa 4 Fasalka 6000

| NPS | Dhererka min of Thread | Dibadda Dia ee Band | Min WT | Xarun ilaa Dhamaad | ||

| B | J | D | G | 90° A | 45° C | |

| 1/2 | 10.9 | 13.6 | 46 | 8.15 | 38 | 28 |

| 3/4 | 12.7 | 13.9 | 56 | 8.53 | 44 | 33 |

| 1 | 14.7 | 17.3 | 62 | 9.93 | 51 | 35 |

| 1.1/4 | 17 | 18 | 75 | 10.59 | 60 | 43 |

| 1.1/2 | 17.8 | 18.4 | 84 | 11.07 | 64 | 44 |

| 2 | 19 | 19.2 | 102 | 12.09 | 83 | 52 |

| 2.1/2 | 23.6 | 28.9 | 121 | 15.29 | 95 | 64 |

| 3 | 25.9 | 30.5 | 146 | 16.64 | 106 | 79 |

| 4 | 27.7 | 33 | 152 | 18.67 | 114 | 79 |

Cabirku waa millimitir ilaa si kale loo tilmaamo.

Cabbirka (B) waa dhererka ugu yar ee dunta ugu fiican.

Dhererka dunta waxtarka leh (B oo lagu daray dunta xididdada si buuxda u samaysmay iyo qolof fidsan) waa inaanay ka yarayn J.

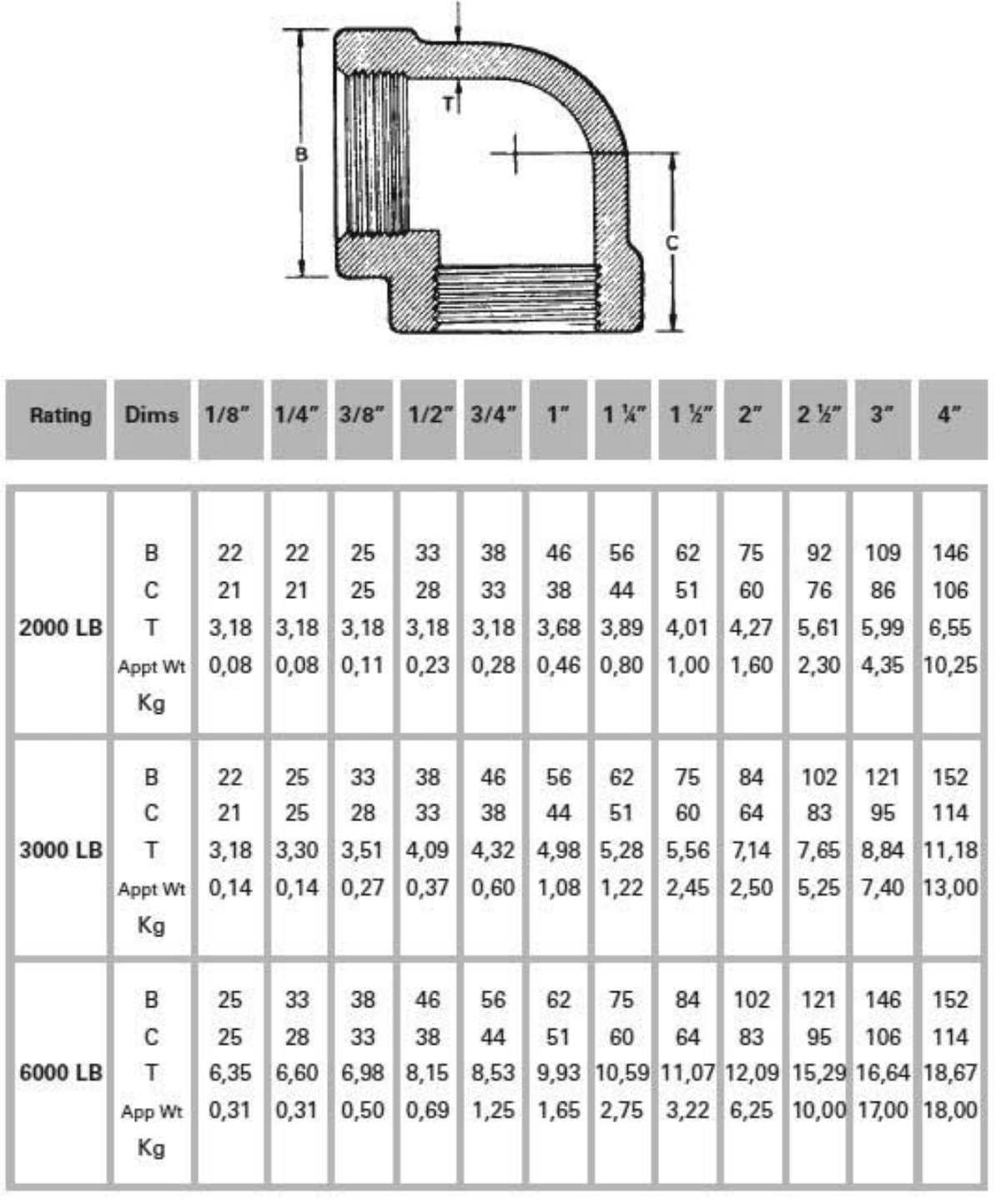

Miisaanka xusulka dunsan

Xajmiga 90 cabbirka xusulka, cabbirka xusulka dunta 90 darajo

Codsiga Xargaha Been abuurka ah ee 90 Degga ah

ASME B16.11.

guud ahaan loo horumariyey buuxinta dalabaadka. Waxaan bixinaa tiro balaadhan oo ah suxulka 90 Degree ee la been abuurtay

iyada oo loo marayo shabakad caalami ah oo laamo kayd ah. Tani 90Deg. Suxulka Threaded waxaa loo isticmaalaa noocyo kala duwan

warshadaha sida:

Birta Aan Lahayn 90° Suxulka Been-abuurka ah ee la Maroojiyey ee loo isticmaalo Dhuumaha Saliida iyo Gaaska

90° Suxulka Been Abuurka ee Been Abuurka ah ee loo isticmaalo Warshadaha Kiimikada

Alloy Steel 90° xusul duuban waxa uu isticmaalaa tuubooyinka

Xadhig Been abuur ah oo 90 Degree ah xusulka tuubada ayaa loo isticmaalaa kuleylinta

90 Degree Suxulka Been Abuurka ah ayaa lagu isticmaalaa Nidaamyada Bixinta Biyaha

ANSI B16.11 Been abuur 90° Suxulka Tubta Maroodiga ah ee loo isticmaalo Warshada Korontada

90° xusul duuban ayaa lagu isticmaalaa Warshada & Saxarka

90° Suxulka Xadhkaha Leh ee Degree ayaa isticmaala Codsiyada Ujeedada Guud

Been abuur 90° Suxulka Radius-ka Dheer ayaa lagu isticmaalaa Warshadaha Warshadaha

90° xusulka fidsan ee been abuurka ah ayaa u adeegsada Warshadaha Soosaarista Cunnada

Xadhkaha la been abuurtay ee 90° Suxulka Radius-gaaban ayaa isticmaala Dhuumaha Dhismaha