Socket Weld 45/90 Deg Elbow

HGFF Group Co., Ltd. provides a variety of products to its customers, especially Socket Weld 90° Elbows. They are offered to clients with the option of customizing the size as per the individual purchasers. Socket Weld is pipe attachment detail in which a pipe is inserted into the recessed area of a valve, fitting or flange. Stainless Steel Socket Weld 90° Elbows make 90° changes of direction in the run of the pipe. These ANSI B16.11 Forged Socket Weld 90° Elbows come in two

types; short radius elbow and long radius elbow. These fittings add pressure losses to the system due to impact, re-acceleration and friction. As an ISO certified company, HGFF Group Co., Ltd is one of the top manufacturers and stockists of ASME B16.11 Socket

Weld 90° Elbows. It is also made available to clients in customized sizes.

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB TO 4″ NB |

| Pressure Class | 3000 LBS, 6000 LBS, 9000 LBS |

| Form | Forged Elbow, 90 Deg Elbow. |

Material & Grades of Forged Socket Weld 90 Deg Elbow :

Stainless Steel Forged Socket Weld 90 Deg Elbow :

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L,

F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld 90 Deg Elbow :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Socket Weld 90 Deg Elbow :

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B,

API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld 90 Deg Elbow :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM /

ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Socket Weld 90 Deg Elbow : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C

71500 ( CU -NI- 70/30)

Nickel Alloy Forged Socket Weld 90 Deg Elbow :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) ,

UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) ,

UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

ASME B16.11 Forged Socket Weld 90 Deg Elbow Available Types

|

Forged Socket weld Elbow 90 Degree |

Forged Socket weld Long Radius 90 Degree Elbows |

|

150 lb. Socket Weld Fittings Pipe Elbow |

Socket weld 90° Short Radius Elbow |

|

ASME B16.11 90 deg Socket weld Elbow |

90 Degree Elbow 3000LB Socket Weld |

|

Socket Weld Fittings 90 Degree Pipe Elbow |

Long Radius Socket Weld 90 Deg. Forged Elbows |

|

ANSI B16.11 90 Degree Forged Elbow |

BS 3799 Forged 90 Degree Elbow |

|

Forged Socket weld 90 Deg Elbow |

Socket weld 90° Pipe Elbow |

|

Socket weld 90deg. Elbow |

High Quality Socket weld 90° Elbow |

|

90° Socket Weld Elbow |

Socket Weld 90 elbow |

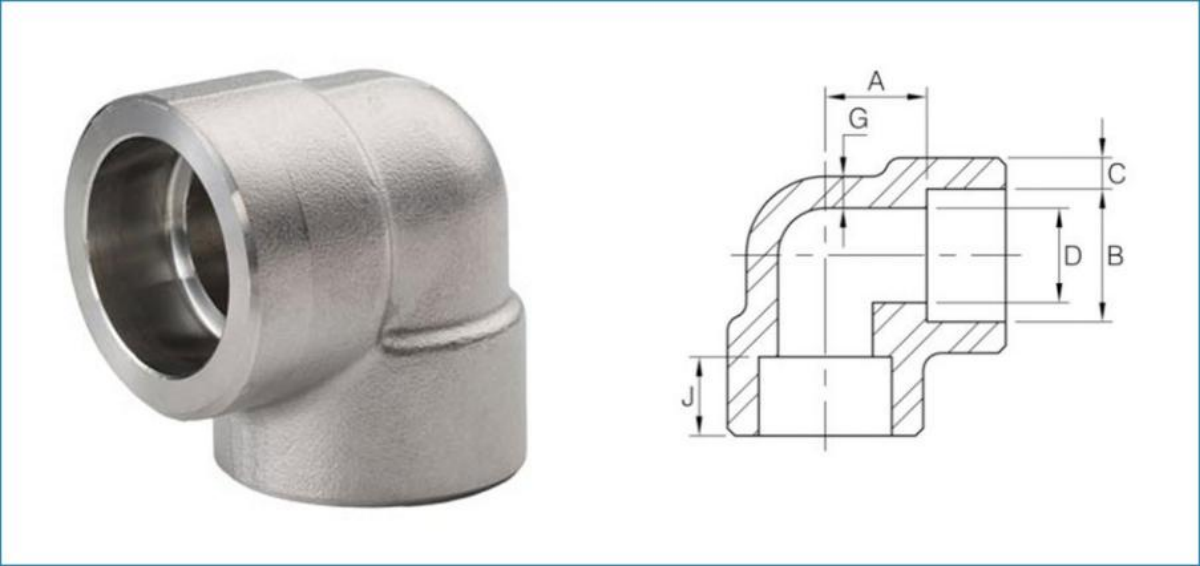

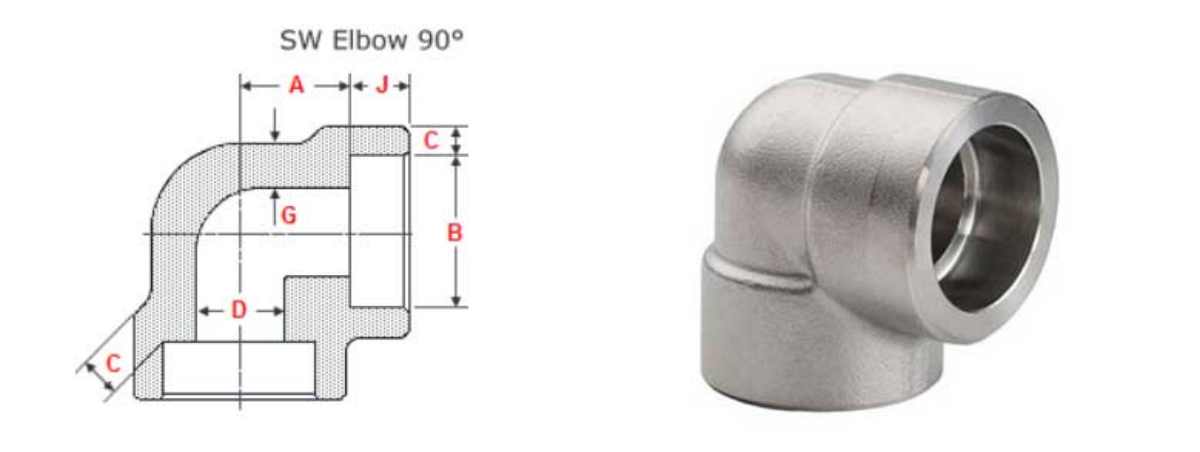

ANSI/ASME B16.11 SOCKET WELD 90 DEGREE ELBOW DIMENSIONS

NPS 1/2 to 4 – 90°/45° Class 3000 Socket Weld 90 Degree Elbow Dimensions

|

NPS |

Socket |

Depth |

Bore |

Socket |

Body |

|

B |

J |

D |

C |

G |

|

|

1/2 |

21.95 |

10 |

16.6 |

4.65 |

3.75 |

|

3/4 |

27.30 |

13 |

21.7 |

4.90 |

3.90 |

|

1 |

34.05 |

13 |

27.4 |

5.70 |

4.55 |

|

1.1/4 |

42.80 |

13 |

35.8 |

6.05 |

4.85 |

|

1.1/2 |

48.90 |

13 |

41.7 |

6.35 |

5.10 |

|

2 |

61.35 |

16 |

53.5 |

6.95 |

5.55 |

|

2.1/2 |

74.20 |

16 |

64.2 |

8.75 |

7.00 |

|

3 |

90.15 |

16 |

79.5 |

9.50 |

7.60 |

|

4 |

115.80 |

19 |

103.8 |

10.70 |

8.55 |

Class 6000 Socket Weld 90° Elbow Dimensions NPS 1/2 to 2

|

NPS |

Socket |

Depth |

Bore |

Socket |

Body |

|

B |

J |

D |

C |

G |

|

|

1/2 |

21.95 |

10 |

12.5 |

5.95 |

4.80 |

|

3/4 |

27.30 |

13 |

16.3 |

6.95 |

5.55 |

|

1 |

34.05 |

13 |

21.5 |

7.90 |

6.35 |

|

1.1/4 |

42.80 |

13 |

30.2 |

7.90 |

6.35 |

|

1.1/2 |

48.90 |

13 |

34.7 |

8.90 |

7.15 |

|

2 |

61.35 |

16 |

43.6 |

10.90 |

8.75 |

Dimensions are in millimeters unless otherwise indicated.

Socket Bore (B) – Maximum and minimum dimensions.

Bore Diameter (D) – Maximum and minimum dimensions.

Socket wall thickness – (C) – Average of Socket wall thickness.

Dimensional tolerances center to bottom of socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2.1/2 to NPS 4 = +/- 2.5 mm

Forged Socket Weld 90 Deg Elbow Application

ASME B16.11 90 Degree Socket weld Elbow are known to deliver exceptional performance and are generally

developed for meeting the demands. We oer a broad range of Forged 90 Degree Socket weld Elbow through a

worldwide network of stock-keeping branches. These 90Deg. Socket weld Elbow is use in various industries like :

Stainless Steel 90° Forged Elbow uses in Oil and Gas Pipeline

90° Forged Pipe Elbow uses in Chemical Industry

Alloy Steel 90° Elbow uses in Plumbing

Forged 90 Degree Pipe Elbow uses in Heating

90 Degree Forged Elbow uses in Water Supply Systems

ANSI B16.9 Forged 90° Pipe Elbow uses in Power Plant

90° Elbow uses in Paper & Pulp Industry

90° Degree Elbow uses in General Purpose Applications

Forged 90° Long Radius Elbow uses in Fabrication Industry

90° Forged Elbow uses in Food Processing Industry

Forged 90° Short Radius Elbow uses in Structural Pipe