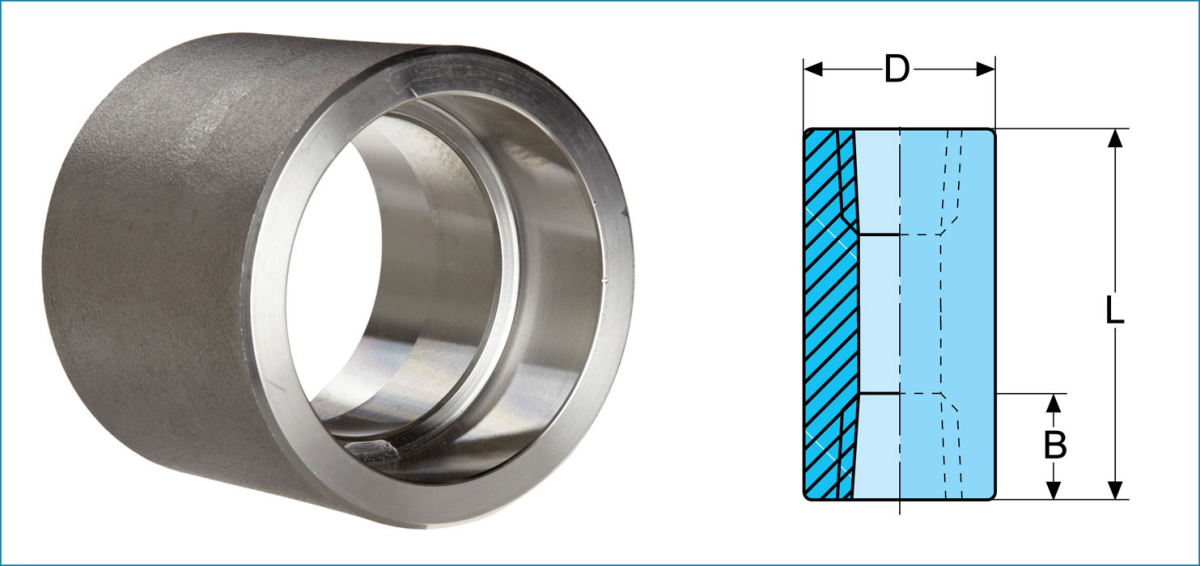

Socket Weld Full Coupling

As an ISO certified company, Liaocheng Shenghao Metal products Co., LTD has made its way into the national and international markets as one of the leading distributors, supplier and stockist of Socket Weld Full Coupling. Socket Weld Full Couplings are used to connect small bore pipes as a projection of a welding effect on the pipe bore. Both the ends of these Full Couplings are threaded. They are highly demanded in the pipe fitting market. These Stainless Steel Socket Weld Half Couplings are rigorously tested to ensure the highest quality and endurance under any extreme conditions. These ANSI B16.11 Forged Socket Weld Full Couplings are used in applications such as pharmaceuticals, shipbuilding, etc. HGFF Group Co., Ltd. owers their clientele the ASME B16.11 Forged Socket Weld Full Couplings at reasonable prices. They are provided in different sizes and thickness for the specific needs of the customers.

ANSI/ASME B16.11 Socket Weld Full Coupling Standard Specification

Socket Weld Full Coupling Sizes

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB TO 4″ NB |

| Pressure Ratings | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Form | Full Couplings, Reducing Coupling |

| Production Grades | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards of Socket Weld Full Coupling

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Forged Socket Weld Full Coupling Material Grades

Nickel Alloy Forged Socket Weld Full Coupling :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Stainless Steel Forged Socket Weld Full Coupling:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld Full Coupling :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Socket Weld Full Coupling:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld Full Coupling :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Socket Weld Full Coupling: ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 45/10) , C 71500 ( CU -NI- 70/30)

ASME B16.11 Forged Socket Weld Full Coupling Available Types

| Forged Socket weld Full Coupling | Socket Weld Full Coupling Class 3000 |

| Socket Weld Reducing Coupling | 3 4 Socket Weld Full Coupling |

| ASME B16.11 Socket Weld Reducing Coupling | 3000LB Socket Weld Full Coupling |

| ANSI B16.11 Forged Socket Weld Full Coupling | Class 6000 Socket Weld Full Coupling |

| Socket Weld Full Coupling Weight | BS 3799 Forged Socket Weld Full Coupling |

| Socket Weld Full Coupling Reducers | High Quality Socket weld Full Coupling |

| 2 Socket Weld Full Coupling | 1/2 Socket Weld Full Coupling |

| 3000# Forged Socket Weld Full Coupling | 3/4 Socket Weld Full Coupling |

| 5 Socket Weld Full Coupling | 1 inch Socket Weld Full Coupling |

| 8 Socket Weld Full Coupling | 2 inch Socket Weld Full Coupling |

| 6000# Socket Weld Full Coupling | 3 inch Socket Weld Full Coupling |

| 6 Socket Weld Full Coupling | 6 inch Socket Weld Full Coupling |

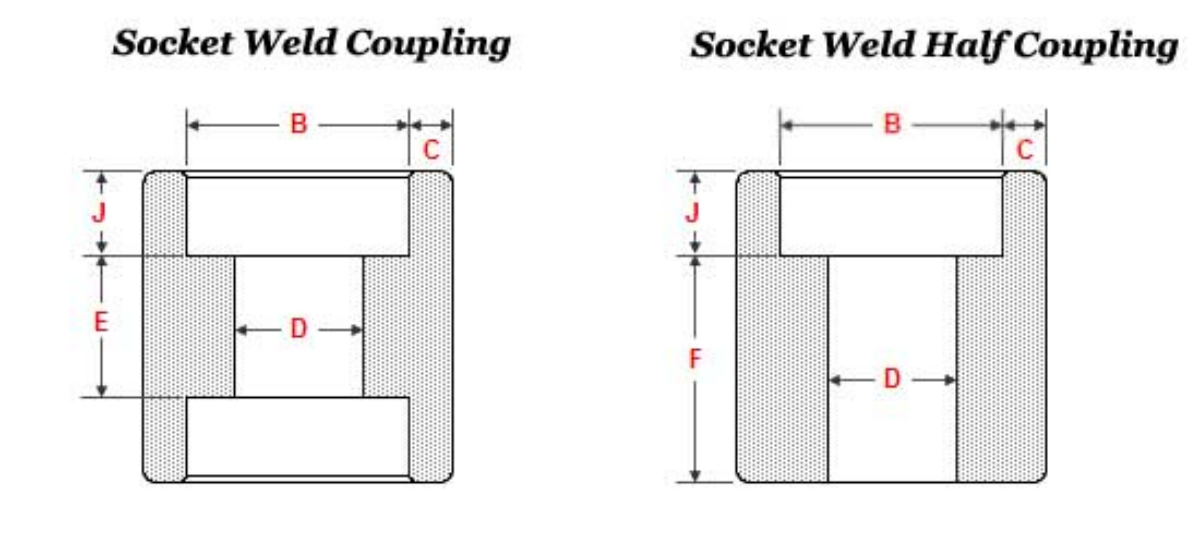

ANSI/ASME B16.11 SOCKET WELD FULL COUPLING DIMENSIONS

Socket Weld Reducing Coupling Dimensions

3000# Socket Weld Coupling Dimensions

| NPS | Socket Bore |

Depth Socket |

Bore DIA |

Socket wall THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

| NPS | Laying lengths | |||

| Coupling E |

Half coupling F |

|||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 | 47.5 | ||

6000# Socket Weld Coupling Dimensions

|

NPS |

Socket |

Depth |

Bore |

Socket |

|

B |

J |

D |

C |

|

|

1/2 |

21.95 |

10 |

12.5 |

5.95 |

|

3/4 |

27.30 |

13 |

16.3 |

6.95 |

|

1 |

34.05 |

13 |

21.5 |

7.90 |

|

1.1/4 |

42.80 |

13 |

30.2 |

7.90 |

|

1.1/2 |

48.90 |

13 |

34.7 |

8.90 |

|

2 |

61.35 |

16 |

43.6 |

10.90 |

|

NPS |

Laying lengths |

|||

|

Coupling |

Half coupling |

|||

|

1/2 |

9.5 |

22.5 |

||

|

3/4 |

9.5 |

23.5 |

||

|

1 |

13 |

29 |

||

|

1.1/4 |

13 |

30 |

||

|

1.1/2 |

13 |

32 |

||

|

2 |

19 |

41 |

||

Dimensions are in millimeters unless otherwise indicated.

Socket Bore (B) – Maximum and minimum dimensions.

Bore Diameter (D) – Maximum and minimum dimensions.

Socket wall thickness – (C) – Average of Socket wall thickness.

Dimensional tolerances center to the bottom of the socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2.1/2 to NPS 4 = +/- 2.5 mm