Socket Weld Union

As a leading exporter, distributor and stockist of Socket Weld Union Fittings, Liaocheng Shenghao Metal products Co., LTD. have made consistent efforts to provide a wide range of products to its customers. It is an ISO certified company that assures that their clients receive high-quality products. Stainless Steel Socket Weld Unions are used in low-pressure piping where it is required to dismantle the pipe often. A Forged Socket Weld Union is a screwed joint design. It consists of three interconnected pieces. This fitting has two internal threads and a centerpiece that draws the ends together when rotated. In order to minimize the warping of the seats, the unions should be screwed tightly before the end are welded. ANSI B16.11 Socket Weld Unionfittings are available in customizable sizes as per the customers’ requests. HGFF Group Co., Ltd flawlessly produces Socket Weld Unions in order to provide ultimate convenience to its clients.

ANSI/ASME B16.11 Socket Weld Union Standard Specification

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB TO 4″ NB |

| Pressure Ratings | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Form | Socket Weld Union, Socket Weld Pipe Union, Socket Weld Orifice Union, Forged Union, Socket Weld Union Fittings |

| Production Grades | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low-temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards of Socket Weld Union Fittings

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Forged Socket Weld Union Material Grades

Nickel Alloy Forged Socket Weld Union :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Stainless Steel Forged Socket Weld Union :

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld Union :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Socket Weld Union :

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld Union :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Socket Weld Union : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 45/10) , C 71500 ( CU -NI- 70/30)

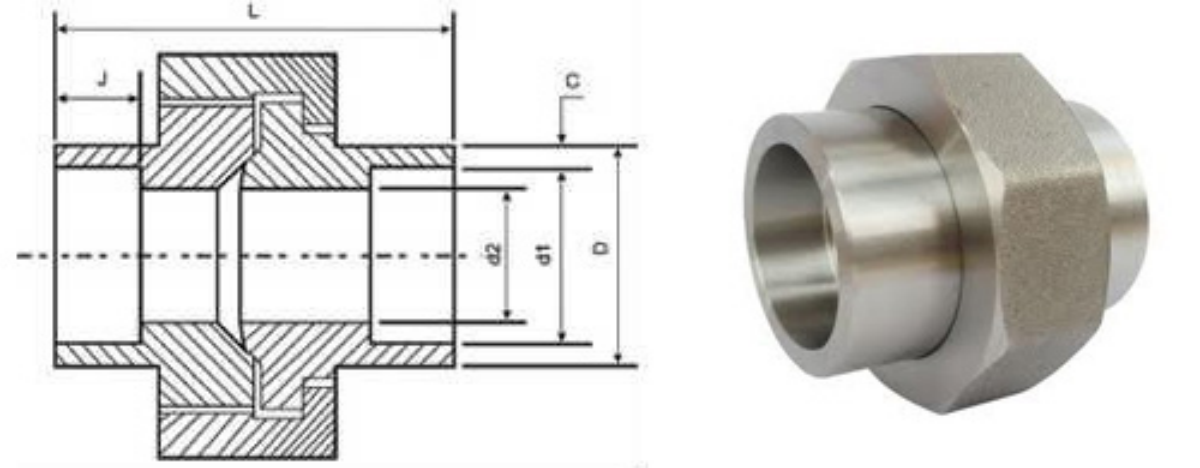

ANSI/ASME B16.11 SOCKET WELD UNION DIMENSIONS

Socket Weld Pipe Union Dimensions

|

Nominal Diameter |

Outside Diameter |

Wall Thickness |

Socket Bore |

Water way Bore |

Depth of Socket |

Length Assem |

|||

|

Dmin |

Cmin |

d1 |

d2 |

Jmin |

L |

||||

|

DN |

NPS |

Socket |

Threaded |

Socket |

Threaded |

Socket |

Socket & Threaded |

Socket |

Socket & Threaded |

|

6 |

1/8 |

21.8 |

14.7 |

3.2 |

2.5 |

10.65 |

6.43 |

10 |

41.4 |

|

8 |

1/4 |

21.8 |

19.0 |

3.3 |

3.1 |

14.10 |

9.45 |

10 |

41.4 |

|

10 |

3/8 |

25.9 |

22.9 |

3.5 |

3.2 |

17.55 |

13.51 |

10 |

46.0 |

|

15 |

1/2 |

31.2 |

27.7 |

4.1 |

3.8 |

21.70 |

17.07 |

10 |

49.0 |

|

20 |

3/4 |

37.1 |

33.5 |

4.3 |

4.0 |

27.05 |

21.39 |

13 |

56.9 |

|

25 |

1 |

45.5 |

41.4 |

5.0 |

4.6 |

33.80 |

27.74 |

13 |

62.0 |

|

32 |

11/4 |

54.9 |

50.5 |

5.3 |

4.9 |

42.55 |

35.36 |

13 |

71.1 |

|

40 |

11/2 |

61.5 |

57.2 |

5.6 |

5.1 |

48.65 |

41.20 |

13 |

76.5 |

|

50 |

2 |

75.2 |

70.1 |

6.1 |

5.6 |

61.10 |

52.12 |

16 |

86.1 |

|

65 |

21/2 |

91.7 |

85.3 |

7.7 |

7.1 |

73.80 |

64.31 |

16 |

102.4 |

|

80 |

3 |

109.2 |

102.4 |

8.4 |

7.7 |

89.80 |

77.27 |

16 |

109.0 |

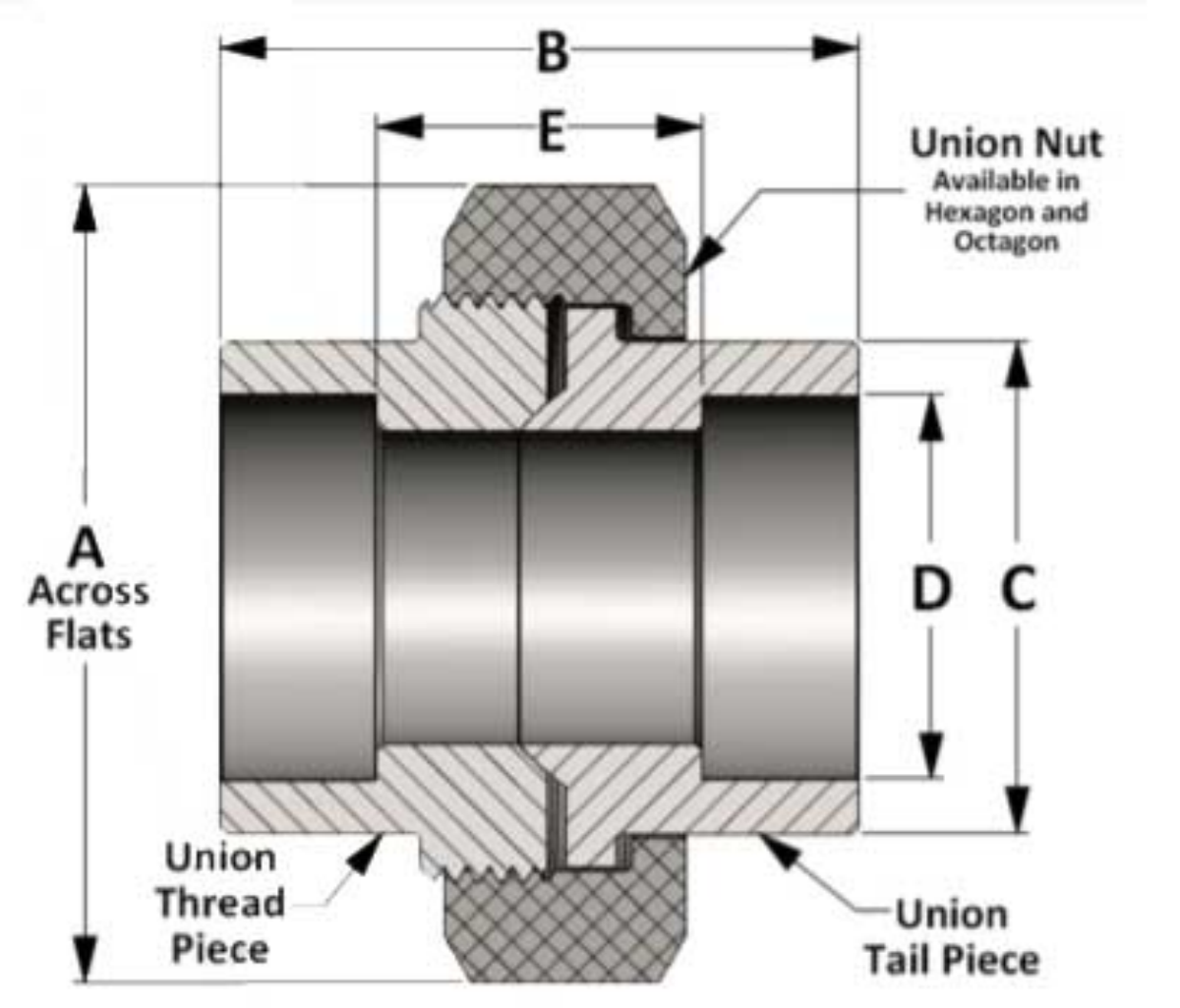

Socket Weld Union Weight2 Socket Weld Union

|

CLASS 3000 Socket Weld Union |

||||||||||||

|

PIPE SIZE |

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1-1/4 |

1-1/2 |

2 |

2-1/2 |

3 |

4 |

|

A |

1.375 |

1.375 |

1.625 |

1.813 |

2.250 |

2.562 |

3.063 |

3.438 |

4.063 |

4.875 |

5.688 |

6.875 |

|

B |

1.688 |

1.688 |

1.813 |

1.938 |

2.250 |

2.438 |

2.813 |

3.000 |

3.375 |

4.031 |

4.313 |

8.000 |

|

C |

0.865 |

0.865 |

1.025 |

1.235 |

1.465 |

1.795 |

2.165 |

2.425 |

2.965 |

3.615 |

4.305 |

5.415 |

|

D |

0.426 |

0.560 |

0.693 |

0.859 |

1.071 |

1.335 |

1.682 |

1.922 |

2.410 |

2.910 |

3.536 |

4.545 |

|

E |

0.813 |

0.813 |

0.938 |

0.938 |

1.125 |

1.188 |

1.438 |

1.500 |

1.625 |

2.250 |

2.313 |

5.000 |

|

LBS |

0.40 |

0.38 |

0.52 |

0.73 |

1.19 |

1.66 |

2.66 |

3.42 |

5.36 |

9.12 |

12.58 |

17.50 |

|

CLASS 6000 Socket Weld Union |

||||||||||||

|

PIPE SIZE |

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1-1/4 |

1-1/2 |

2 |

2-1/2 |

3 |

4 |

|

A |

1.375 |

1.625 |

1.813 |

2.250 |

2.562 |

3.063 |

3.438 |

4.063 |

4.875 |

5.688 |

6.875 |

— |

|

B |

1.688 |

1.813 |

1.938 |

2.250 |

2.438 |

2.813 |

3.000 |

3.375 |

4.031 |

4.313 |

8.000 |

— |

|

C |

0.865 |

1.025 |

1.235 |

1.465 |

1.795 |

2.165 |

2.425 |

2.965 |

3.615 |

4.305 |

5.415 |

— |

|

D |

0.426 |

0.560 |

0.693 |

0.859 |

1.071 |

1.335 |

1.682 |

1.922 |

2.410 |

2.910 |

3.536 |

— |

|

E |

0.813 |

0.813 |

0.938 |

0.938 |

1.125 |

1.188 |

1.438 |

1.500 |

1.625 |

2.250 |

5.750 |

— |

|

LBS |

0.48 |

0.56 |

0.75 |

1.35 |

2.01 |

3.17 |

3.92 |

6.60 |

10.12 |

14.00 |

40.891 |

— |

|

CLASS 9000 Socket Weld Union |

||||||||||||

|

PIPE SIZE |

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1-1/4 |

1-1/2 |

2 |

2-1/2 |

3 |

4 |

|

A |

1.750 |

2.000 |

2.250 |

2.563 |

3.063 |

3.688 |

4.313 |

5.000 |

5.750 |

6.875 |

— |

— |

|

B |

2.500 |

2.563 |

2.938 |

3.250 |

3.750 |

4.000 |

4.625 |

4.813 |

5.563 |

6.25 |

— |

— |

|

C |

1.000 |

1.250 |

1.500 |

1.750 |

2.250 |

2.500 |

3.000 |

3.625 |

4.250 |

5.000 |

— |

— |

|

D |

0.426 |

0.560 |

0.693 |

0.859 |

1.071 |

1.335 |

1.682 |

1.922 |

2.410 |

2.910 |

— |

— |

|

E |

1.720 |

1.688 |

1.938 |

2.000 |

2.375 |

2.375 |

3.000 |

2.938 |

3.188 |

3.750 |

— |

— |

|

LBS |

0.89 |

1.045 |

1.955 |

3.29 |

5.34 |

7.99 |

12.73 |

18.34 |

26.36 |

37.07 |

— |

|

Forged Socket Weld Pipe Cap Application

ASME B16.11 Socket weld Pipe Cap are known to deliver exceptional performance and are generally developed

for meeting the demands. We offer a broad range of Forged Socket weld Pipe Cap through a worldwide network

of stock-keeping branches. This Forged Socket weld Pipe Cap is used in various industries like :

Stainless Steel Forged Socket weld Pipe Cap uses in Oil and Gas Pipeline

Forged Socket weld Pipe Cap uses in Chemical Industry

Alloy Steel Socket weld Pipe Cap uses in Plumbing

Forged Socket weld End Pipe Caps uses in Heating

Socket weld Forged Pipe Caps uses in Water Supply Systems

ANSI B16.11 Forged Socket weld Pipe Cap uses in Power Plant

Socket weld Pipe Cap uses in Paper & Pulp Industry

Forged Socket weld Pipe Caps uses in General Purpose Applications

Forged Socket weld Pipe Cap uses in Fabrication Industry

Forged Socket weld Pipe Cap uses in Food Processing Industry

Forged Socket weld Pipe Caps uses in Structural Pipe