Flange dimension inspection: lejoe la sekhutlo la bonono bo nepahetseng ba tekanyo le polokeho ea indasteri

Tsamaisong e rarahaneng ea lipeipi tsa indasteri, li-flange, tse bonahalang li se na thuso ea likaroloana tse hokahanyang, li phetha karolo ea bohlokoa. Li tšoana le manonyeletso methapong ea mali, ho netefatsa hore mokelikeli o phallang ka har'a liphaephe le ts'ebetso e tsitsitseng ea tsamaiso. Har'a bona, tlhahlobo e nepahetseng ea litekanyo tsa flange e fetohile sehokelo sa bohlokoa ho netefatsa polokeho ea indasteri le ho ntlafatsa katleho ea tlhahiso.

Tlhahlobo ea Flange dimension, joalo ka ha lebitso le fana ka maikutlo, ke tekanyo e hlokolosi le netefatso ea likarolo tse fapaneng tsa li-flanges. Ho tloha bophara bo ka ntle ho ea ho bophara bo ka hare, ho tloha ho botenya ho isa ho bophara ba lesoba la bolt, lintlha tsohle li hloka ho lekanngoa ka thata le ho bapisoa ho netefatsa ho khomarela ka hloko ho litšoantšo tsa meralo le litekanyetso tsa indasteri. Sena ha se feela mosebetsi oa theknoloji, empa hape ke bonono bo phehellang ho nepahala.

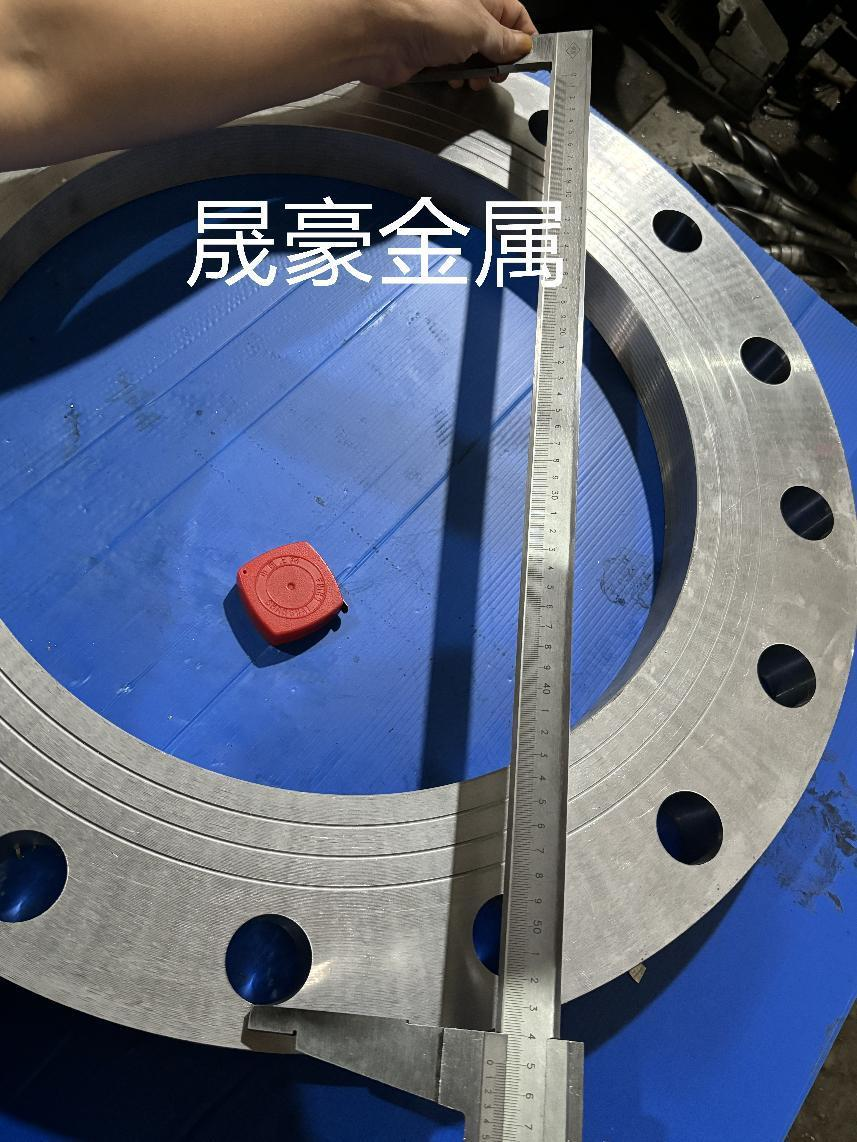

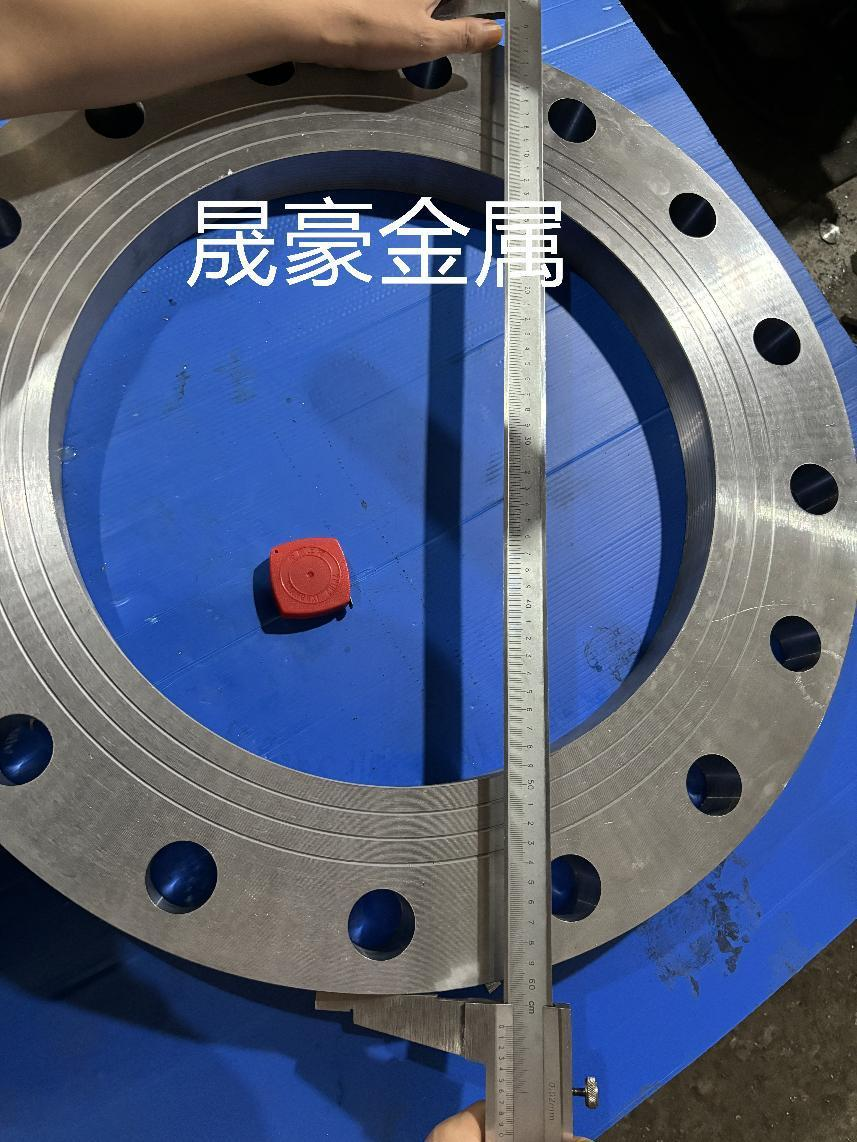

Khetho le tšebeliso ea lisebelisoa tsa ho lekanya ke tsa bohlokoa ts'ebetsong ea tlhahlobo ea boholo ba flange. Lisebelisoa tse nepahetseng joalo ka li- vernier caliper, micrometer, le li-gauge tsa bophara ba kahare, joalo ka lithipa tse betlang matsohong a litsebi tsa mesebetsi ea matsoho, li hloka hore matsoho a hloahloa a bahlahlobi a hlahise litekanyo tsa 'nete tsa flanges. 'Me tekanyo e' ngoe le e 'ngoe ke teko ea mamello le masene a bahlahlobi. Ho se tsotelle leha e le hofe ho ka ba le tšusumetso e ke keng ea lekanngoa ho kenngoa le ho sebelisoa ho latelang.

Tlhahlobo e nepahetseng ea litekanyo tsa flange ke ea bohlokoa haholo bakeng sa polokeho ea indasteri. Boholo bo boholo kapa bo bonyenyane haholo bo ka lebisa likamanong tse hlephileng pakeng tsa flanges le liphaephe, ho baka liphello tse tebileng tse kang ho lutla, ho thothomela, esita le ho phatloha. Ka hona, flange e 'ngoe le e 'ngoe e tlameha ho hlahlojoa ka mokhoa o tiileng pele e tloha fekthering ho netefatsa hore e ka kopanngoa ka ho phethahetseng tsamaisong ea lipeipi le ho sireletsa ts'ebetso e sireletsehileng ea indasteri.

Ho feta moo, tlhahlobo ea boholo ba flange e boetse ke tiisetso ea bohlokoa bakeng sa ho ntlafatsa katleho ea tlhahiso. Ho bapisa boholo bo nepahetseng ho ka fokotsa haholo nako ea ho lokisa le ho lokisa nakong ea ho kenya, le ho ntlafatsa katleho ea mosebetsi. Ka nako e ts'oanang, e boetse e thusa ho fokotsa ts'ebetso e ncha le sekhechana se bakoang ke ho se lumellane ha boholo, litšenyehelo tse tlase tsa tlhahiso, le ho kenya matla a macha ntlafatsong e tsitsitseng ea likhoebo.

Ka kakaretso, tlhahlobo ea boholo ba flange hase feela mosebetsi oa theknoloji, empa hape ke mosebetsi oa bohlokoa o amanang le polokeho ea indasteri le katleho ea tlhahiso. E hloka hore bahlahlobi ba be le boikarabelo bo phahameng le bokhoni ba setsebi, ho lekanya ka nepo le ho laola boholo ba flange ka 'ngoe, le ho kenya letsoho boitekong ba bona ts'ebetsong e sireletsehileng le e sebetsang ea indasteri. Ntlafatsong ea kamoso ea indasteri, re lebelletse boiqapelo le tsoelo-pele e tsoelang pele tlhahlobong ea boholo ba flange, ho fana ka tiisetso e tiileng bakeng sa polokeho le botsitso ba lipeipi tsa indasteri.

Nako ea poso: Sep-23-2024