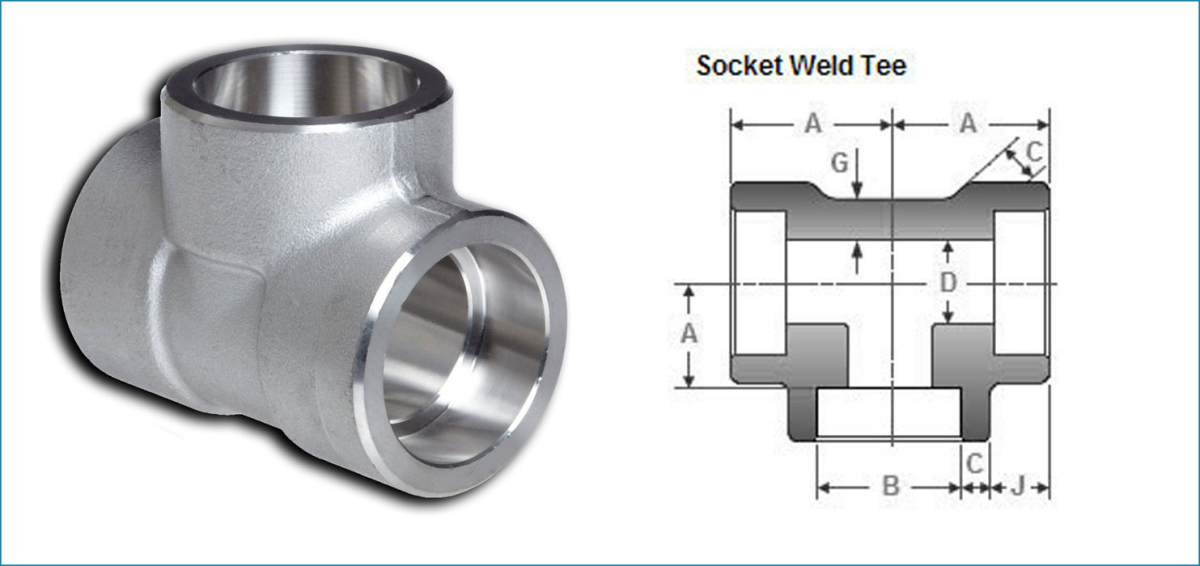

Socket Weld Tee

Liaocheng Shenghao Metal products Co., LTD mangrupikeun produsén otorisasi, supplier sareng eksportir ASME B16.11 Socket Weld Tee, diproduksi dumasar kana parameter kualitas internasional. Fittings Socket Weld Tee kami asalna dina rupa-rupa kelas sareng kelas bahan pikeun sababaraha aplikasi industri. Kami ditawarkeun Forged Socket Weld Sarua Tee ngajadikeun cabang 90 ° ti ngajalankeun utama pipa.

Kami nyayogikeun Socket Weld Tees ieu pikeun sababaraha aplikasi industri sapertos pamrosésan kimia, kilang minyak, pétrokimia sareng seueur industri anu sanés. ANSI B16.11 Forged Socket Weld Tee mangrupikeun bukti bocor sareng tahan korosi. Socket Weld Sarua Tees dipaké pikeun garis toksik conveying bahan kaduruk atawa mahal mana teu leakage bisa diijinkeun, sarta pikeun uap 300 mun 600 PSI.

ANSI / ASME B16.11 Socket Weld Tee Standar spésifikasi

| Diménsi | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Ukuran | 1/2″NB KA 4″NB IN |

| Kelas | 3000 LBS, 6000 LBS, 9000 LBS |

| Tipe | Socket Weld (S/W) & SCREWED (SCRD) - NPT, BSP, BSPT |

| Wangun | Sockte Weld Tee, Socket Weld Sarua Tee |

| Kelas Produksi | Stainless Steel, Alloy Steel, Duplex, Nikel Alloys, Low Suhu Steel, Karbon Steel, Cupro Nikel |

Standar Manufaktur Socket Weld Sarua Tee

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Ngajalin stop kontak Weld Tee Bahan sasmita

Nikel Alloy Ngajalin Socket Weld Tee:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400 ) , UNS ALL 2000 UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELOY C 276)

Stainless Steel Forged Socket Weld Tee:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321, F321, F321, F321H F347H, F904L, ASTM A312/A182 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld Tee:

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Baja Karbon Ngajalin Socket Weld Tee:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Paduan Steel Forged Socket Weld Tee:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 CR2, 1/4 CR, 1 CR1/4 CR 91

Tambaga Alloy Steel ngajalin stop kontak Las Tee: ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30)

ASME B16.11 Ngajalin stop kontak Weld Tee Sadia Tipe

| Ngajalin Socket weld Tee | Stop kontak las Ngurangan Tee |

| 150 pon stop kontak las fittings pipe Tee | 2 inci Socket weld Tee |

| ASME B16.11 Socket weld Sarua Tee | 3000LB stop kontak Weld Tee |

| Soket Weld Tee fittings | kelas 6000 Stop kontak Weld ngajalin Tee |

| ANSI B16.11 Ngajalin stop kontak Las Tee | BS 3799 ngajalin stop kontak Weld Tee |

| Ngajalin stop kontak weld Sarua Tee | Socket Weld Sarua Tee Beurat |

| Stop kontak las Tee Reducer | High Quality stop kontak weld Tee |

| 1 inci stop kontak Weld Tee | Socket Weld pipe Tee |

ASME B16.11 ngajalin stop kontak las 90 Deg siku Sadia Tipe

| Ngajalin stop kontak las siku 90 Gelar | Ngajalin stop kontak las Long Radius 90 gelar Elbows |

| 150 pon stop kontak Weld fittings pipe siku | las stop kontak 90 ° Short Radius siku |

| ASME B16.11 90 deg Socket weld Siku | 90 Gelar siku 3000LB stop kontak Weld |

| Stop kontak Weld fittings 90 Gelar pipe siku | Panjang Radius stop kontak Las 90 Deg. Siku Ditempa |

| ANSI B16.11 90 Gelar ngajalin siku | BS 3799 Ngajalin 90 Gelar Siku |

| Ngajalin stop kontak weld 90 Deg siku | Socket weld 90 ° Pipa siku |

| Socket weld 90deg. siku | High Quality stop kontak weld 90 ° siku |

| 90 ° stop kontak Weld siku | Socket Weld 90 siku |

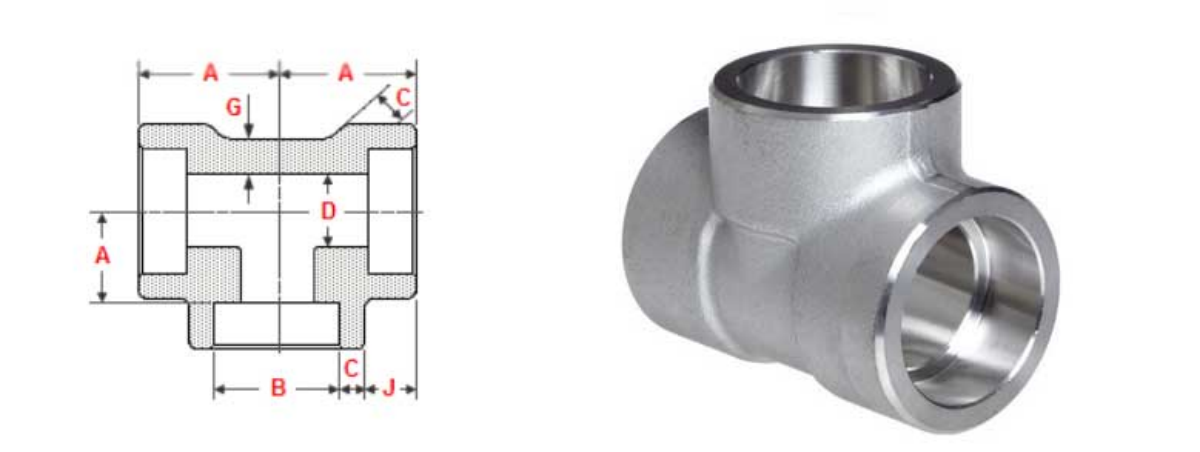

ANSI / ASME B16.11 diménsi tee las stop kontak

Socket Weld Sarua Tee Dimensi

Kelas 3000 Socket Weld Tee Dimensi NPS 1/2 ka 2

| NPS | Socket Bore | Socket jero | Bosen dia |

| B | J | D | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 | 13 | 41.7 40.1 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 | 3.75 | 15.5 |

| 3/4 | 4.90 4.25 | 3.90 | 19.5 |

| 1 | 5.70 5.00 | 4.55 | 22 |

| 1.1/4 | 6.05 5.30 | 4.85 | 27 |

| 1.1/2 | 6.35 5.55 | 5.10 | 32 |

| 2 | 6.95 6.05 | 5.55 | 38 |

| 2.1/2 | 8.75 7.65 | 7.00 | 41.5 |

| 3 | 9.50 8.30 | 7.60 | 57.5 |

| 4 | 10.70 9.35 | 8.55 | 66.5 |

Kelas 6000 Socket Weld Tee Diménsi NPS 1/2 ka 2

| NPS | Socket Bore | Socket jero | Bosen dia |

| B | J | D | |

| 1/2 | 21.95 21.70 | 10 | 12.5 11 |

| 3/4 | 27.30 27.05 | 13 | 16.3 14.8 |

| 1 | 34.05 33.80 | 13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 | 13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 | 13 | 34.7 33.2 |

| 2 | 61.35 61.10 | 16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 | 4.80 | 19.5 |

| 3/4 | 6.95 6.05 | 5.55 | 22.5 |

| 1 | 7.90 6.95 | 6.35 | 27 |

| 1.1/4 | 7.90 6.95 | 6.35 | 32 |

| 1.1/2 | 8.90 7.80 | 7.15 | 38 |

| 2 | 10.90 9.50 | 8.75 | 41 |

Diménsi aya dina milimeter iwal disebutkeun béda.

Bore stop kontak (B) - Maksimum jeung dimensi minimum.

Diaméterna bore (D) - Maksimum jeung dimensi minimum.

Ketebalan témbok stop kontak - (C) - Rata-rata ketebalan témbok stop kontak.

Puseur kasabaran diménsi ka handapeun stop kontak - (A)

NPS 1/2 jeung NPS 3/4 = +/- 1,5 mm

NPS 1 mun NPS 2 = +/- 2 mm

NPS 2,1/2 mun NPS 4 = +/- 2,5 mm

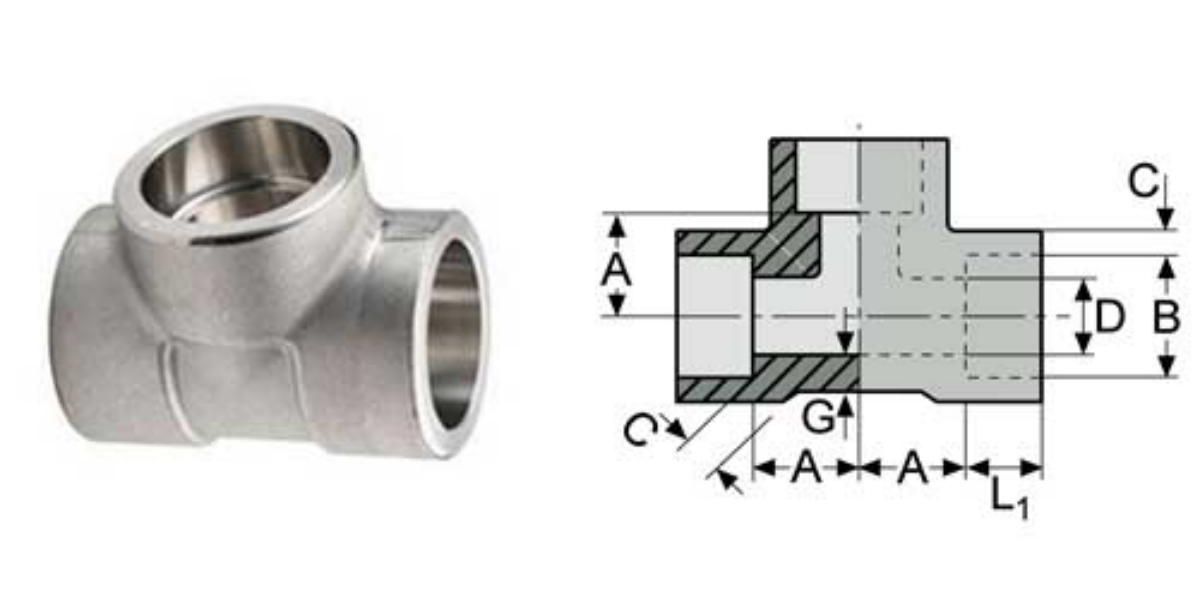

Socket weld Sarua Tee Beurat

| Ukuran pipa nominal | B | L1 | C | G | D | A | Beurat |

| di. | mm | stop kontak | mm | mm | mm | mm | ~kg/p |

| 1/4 | 14.20 | 9.53 | 3.30 | 3.02 | 8.86 | 11.11 | 0.11 |

| 1 | 33.90 | 12.50 | 4.98 | 4.55 | 26.26 | 22.23 | 0.65 |

Ngajalin Socket Tee Aplikasi

ASME B16.11 45 Degree Socket weld Tee dipikanyaho nganteurkeun kinerja anu luar biasa sareng umumna

dimekarkeun pikeun minuhan tungtutan. Urang ower sauntuyan lega Ngajalin 45 Gelar Socket weld Tee ngaliwatan a

jaringan sadunya cabang nyimpen saham. Ieu 45 Deg. Socket weld Tee dianggo dina sababaraha industri sapertos:

Stainless Steel 45 ° Ngajalin Tee dianggo dina Pipa Minyak sareng Gas

45 ° Ngajalin Pipe Tee ngagunakeun dina Industri Kimia

Alloy Steel 45 ° Tee ngagunakeun dina Plumbing

Ngajalin 45 Gelar Pipe Tee dianggo dina Pemanasan

45 Gelar Forged Tee dianggo dina Sistem Pasokan Cai

ANSI B16.9 Ngajalin 45 ° Pipe Tee ngagunakeun dina Power Plant

45 ° Tee dianggo dina Industri Kertas & Bubur

45 ° Gelar Tee dianggo dina Aplikasi Tujuan Umum

Ngajalin 45 ° Long Radius Tee dianggo dina Industri Fabrikasi

45 ° Ngajalin Tee ngagunakeun dina Industri Pangolahan Pangan

Ngajalin 45 ° Short Radius Tee dianggo dina Pipa Struktural