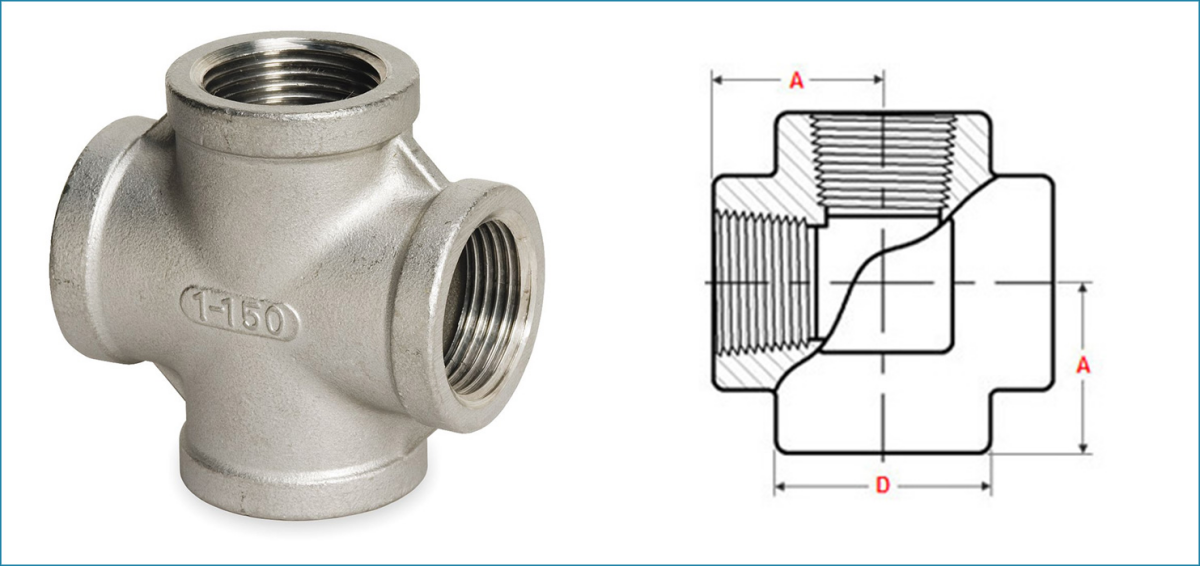

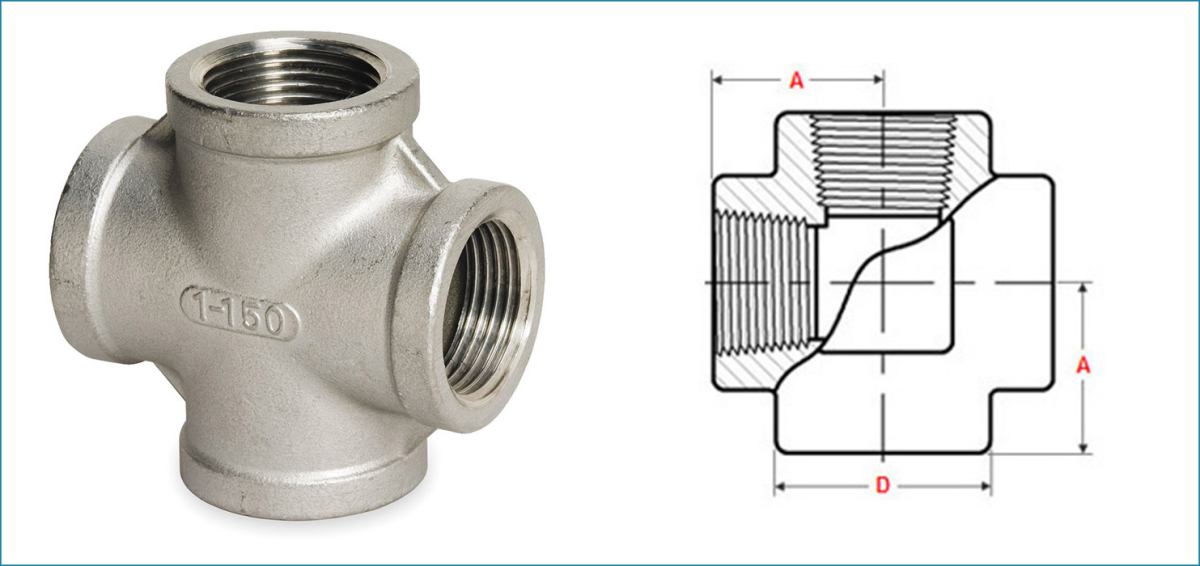

Threaded / Screwed Palang

Liaocheng Shenghao Metal produk Co., LTD. nyaéta produsén ngarah, stockist jeung supplier of Threaded / Screwed Palang fittings. Ieu mangrupikeun perusahaan anu parantos nampi sertifikasi ISO sareng anu nyayogikeun genah pamungkas pikeun para nasabahna. fittings Palang Threaded nyieun hiji 90 ° cabang ti ngajalankeun utama pipa. Éta tiasa dianggo pikeun nyayogikeun sealing bébas bocor sareng torsi dina sambungan pipa atanapi pipa. Ieu mangrupikeun pas anu jarang dianggo dina sistem perpipaan tapi mangrupikeun bagian penting tina éta. Stainless Steel Screwed Palang boga dua jenis; lempeng jeung ngurangan. Kelengkapan ieu ngagaduhan hiji inlet sareng tilu outlet atanapi sabalikna. ANSI B16.11 Threaded / Screwed Crosses dihasilkeun HGFF Group Co., Ltd. dirancang sapanjang garis tina standar internasional.

ANSI / ASME B16.11 Threaded pipe Palang spésifikasi Standar

| Diménsi | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Ukuran | 1/8″~4″ (DN6~DN100) |

| Kelas | 3000 LBS, 6000 LBS, 9000 LBS |

| Tipe | Socket Weld (S/W) & SCREWED (SCRD) - NPT, BSP, BSPT |

| Wangun | Palang Ulir, Palang Pipa Ulir, Palang Sarua Ulir |

| Jasa Nilai Tambah: | Galvanizing Dicelup Panas, Epoxy & FBE Coating, Electro Polish, Pasir Blasting, Threading, Soldering |

| Kelas Produksi: | Stainless Steel, Alloy Steel, Duplex, Nikel Alloys, Low Suhu Steel, Karbon Steel, Cupro Nikel |

Standar Manufaktur of Threaded Sarua Cross

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Threaded Palang Bahan sasmita

Stainless Steel Ditempa Threaded Pipa Palang:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321, F321, F321, F321H F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Threaded Sarua Palang:

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Baja Karbon Ditempa Threaded Cross:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Ngajalin Threaded Sarua Palang:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 CR2, 1/4 CR, 1 CR1/4 CR 91

Tambaga Alloy Steel Ngajalin Threaded Cross: ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30)

Nikel Alloy Ngajalin Threaded Sarua Palang:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400 ) , UNS ALL 2000 UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELOY C 276)

ANSI / ASME B16.11 THREADED cross diménsi

Threaded Pipa Cross Dimensi Bagan

Threaded Cross Dimensi NPS 1/2 nepi ka 4 Kelas 2000

| NPS | Min Panjang Thread | Luar Dia of Band D | Puseur ka Tungtung A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Threaded Sarua Cross Kelas 3000 Dimensi NPS 1/2 ka 4

| NPS | Min Panjang Thread | Luar Dia of Band D | Puseur ka Tungtung A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

Threaded Cross Dimensi NPS 1/2 nepi ka 4 Kelas 6000

| NPS | Min Panjang Thread | Luar Dia of Band D | Puseur ka Tungtung A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Diménsi aya dina milimeter iwal disebutkeun béda.

Diménsi B nyaéta panjang minimum benang sampurna.

Panjang benang anu gunana (B tambah benang kalayan akar anu pinuh kabentuk sareng puncak datar) teu kedah kirang ti J.

ASME B16.11 Threaded Palang Beurat

| Kelas 2000 | Nominal | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| Pipa | |||||||||||||

| Ukuran | |||||||||||||

| A | – | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 3 | 3 3/8 | 4 3/16 | |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| Wt | – | 0.5 | 0.46 | 0.777 | 1.125 | 1.688 | 2.45 | 3.188 | 5.56 | 16.438 | 19.5 | 32.688 | |

| Kelas 3000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 1/2 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| Wt | 0.438 | 0,567 | 0.97 | 1.5 | 2.5 | 3.62 | 4.125 | 6.5 | 8.125 | 16.75 | 25.675 | 32 | |

| Kelas 6000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 3/16 | 4 1/2 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | 6 | |

| Wt | 0,563 | 1.188 | 1.5 | 2.75 | 4.313 | 6.625 | 10.75 | 11.5 | 22.188 | 27.5 | 54 | 43.5 | |

Ngajalin Threaded / Screwed Sarua Aplikasi Palang

ASME B16.11 Threaded Cross dipikawanoh pikeun nganteurkeun kinerja luar biasa tur umumna dimekarkeun pikeun

minuhan tungtutan. Kami nawiskeun sajumlah ageung Forged Screwed Cross ngalangkungan jaringan cabang jaga saham sadunya. Palang Berulir Tempa ieu dianggo dina sababaraha industri sapertos:

Stainless Steel Forged Threaded Cross dianggo dina Pipa Minyak sareng Gas

Ngajalin Threaded Cross ngagunakeun dina Industri Kimia

Alloy Steel Threaded Sarua Palang ngagunakeun Plumbing

Ngajalin Screwed Sarua Palang ngagunakeun dina Pemanasan

Threaded Ngajalin Sarua Palang ngagunakeun dina Systems Supply Cai

ANSI B16.11 Ngajalin Threaded Cross ngagunakeun dina Power Plant

Utas Sarua Palang dianggo dina Industri Kertas & Pulp

Ngajalin Screwed Sarua Palang ngagunakeun dina Tujuan Umum Aplikasi

Ngajalin Threaded Cross ngagunakeun dina Industri Fabrikasi

Ngajalin Screwed Sarua Palang ngagunakeun dina Industri Pangolahan Pangan

Ngajalin Threaded Sarua Palang ngagunakeun dina Pipa Struktural