Threaded / Screwed Tee

Liaocheng Shenghao Metal products Co., LTD is a highly acclaimed manufacturer of ASME B16.11 Threaded Tee, which is very much resistant to chemical corrosion and oxidation (corrosion resistant), and has some high stress-rupture effectiveness and low creep rates under high stresses at temperatures after suitable heat treatment. Threaded Equal Tee is either used to combine or split a fluid flow. Threaded Pipe Tee has the same inlet and outlet sizes. Threaded Tee Fittings are used in different industries applications like chemical processing, oil refineries, petrochemical and many other industries. We also supply Forged Threaded Tee in customized size as per customer requirement. We manufacture Threaded Tee Dimensions in accordance with ASME B16.11 / BS 3799. The B16.11 standard covers pressure-temperature ratings, dimensions, marking, tolerances and material requirements. We are specialized in supplying Threaded Tee in three pressure ratings: class 2000, Class 3000 and 6000 at a reasonable price in China. Check Threaded Pipe Tee Dimensions Chart before buy.

ANSI/ASME B16.11 Threaded Pipe Tee Standard Specification

|

Dimensions |

ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

|

Size |

1/8″~4″ (DN6~DN100) |

|

Class |

3000 LBS, 6000 LBS, 9000 LBS |

|

Type |

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

|

Form |

Threaded Tee, Threaded Pipe Tee, Threaded Equal Tee |

|

Value Added Services: |

Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

|

Production Grades: |

Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards of Threaded Equal Tee

|

ASME: |

ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

|

DIN: |

DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

|

EN: |

EN10253-1, EN10253-2 |

ASME B16.11 Threaded Tee Material Grades

Stainless Steel Forged Threaded Tee :

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Threaded Equal Tee:

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Threaded Tee:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Threaded Equal Tee :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Threaded Tee : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

Nickel Alloy Forged Threaded Equal Tee:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

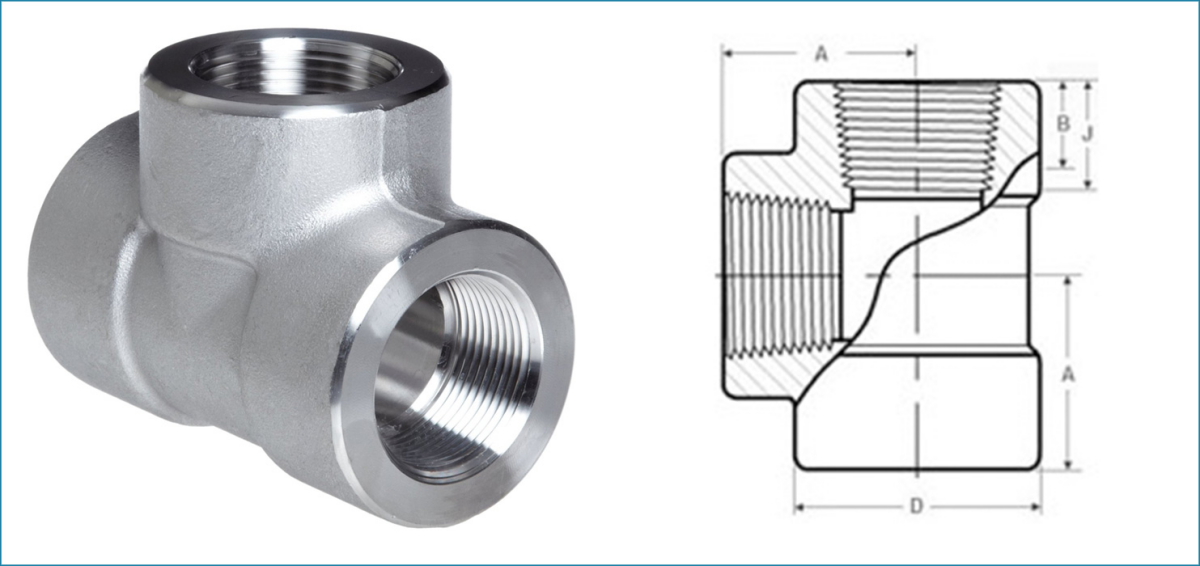

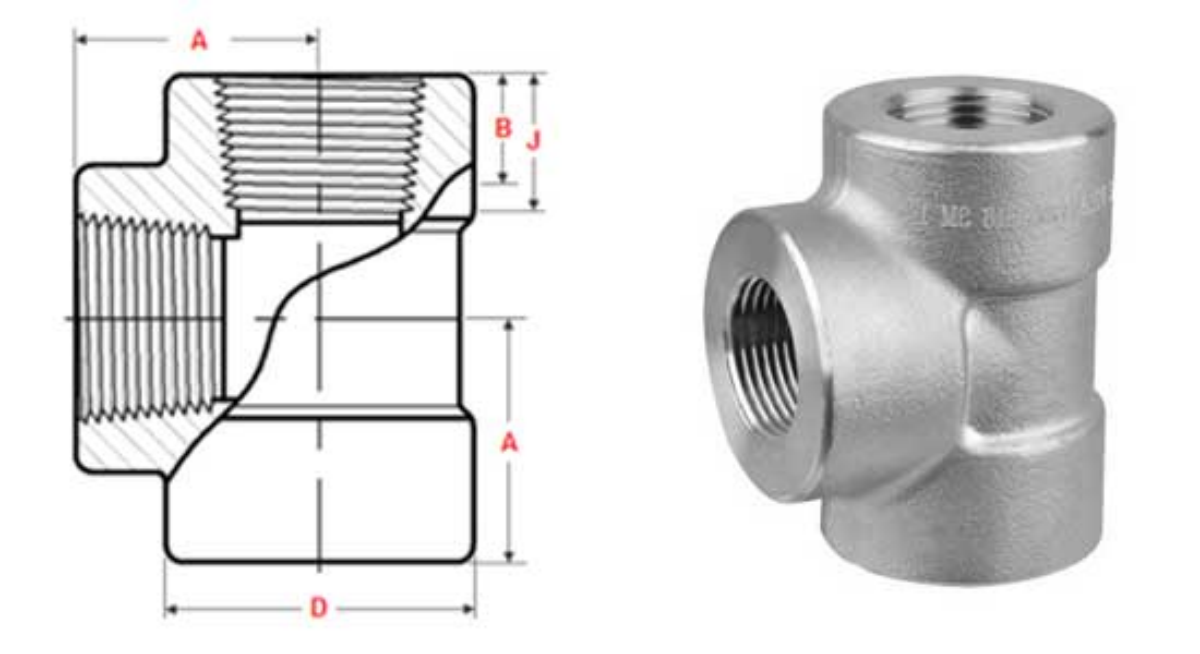

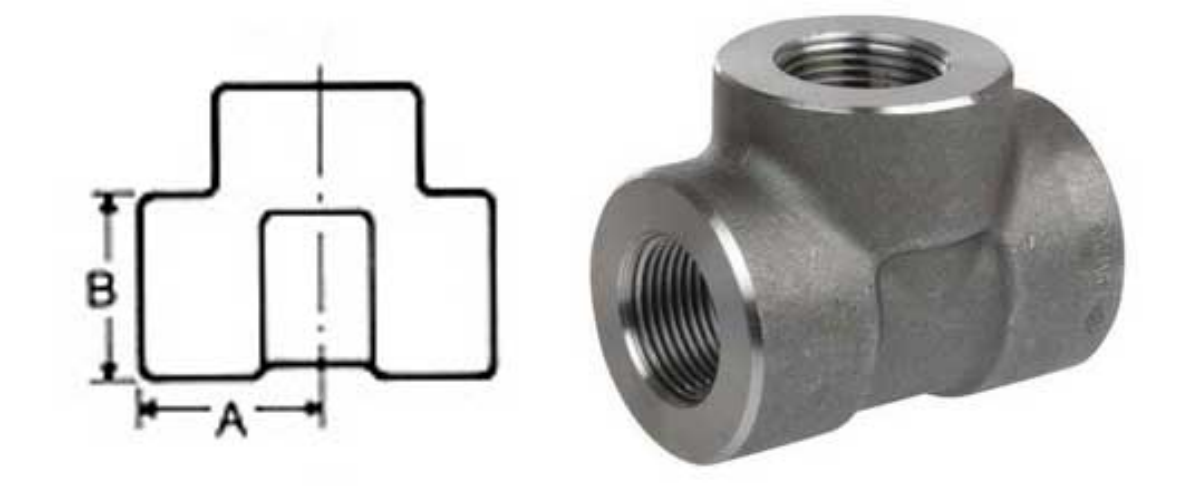

ANSI/ASME B16.11 THREADED TEE DIMENSIONS

Threaded Pipe Tee Dimensions Chart

Threaded Tee Dimensions, 3/4 Threaded Tee Dimensions NPS 1/2 to 4 Class 2000

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Threaded Equal Tee Class 3000 Dimensions NPS 1/2 to 4

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

3/4 Threaded Tee Dimensions NPS 1/2 to 4 Class 6000

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Dimensions are in millimeters unless otherwise indicated.

Dimension B is minimum length of perfect thread.

The length of useful thread (B plus threads with fully formed roots and flat crests) shall not be less than J.

|

Class 2000 |

Nominal Pipe Size |

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1 1/4 |

1 1/2 |

2 |

2 1/2 |

3 |

4 |

|

B |

– |

29/32 |

1 1/16 |

1 5/16 |

1 9/16 |

1 27/32 |

2 7/32 |

2 1/2 |

3 1/32 |

3 11/16 |

4 5/16 |

5 3/4 |

|

|

F |

– |

3/4 |

3/4 |

1 |

1 1/8 |

1 1/4 |

1 5/16 |

1 3/8 |

1 11/16 |

2 1/16 |

2 1/2 |

3 1/8 |

|

|

Wt |

– |

0.188 |

0.236 |

0.435 |

0.74 |

1.058 |

1.375 |

1.74 |

2.883 |

7.75 |

11.313 |

19.125 |

|

|

|

|||||||||||||

|

Class 3000 |

|

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1 1/4 |

1 1/2 |

2 |

2 1/2 |

3 |

4 |

|

B |

29/32 |

1 1/16 |

1 5/16 |

1 9/16 |

1 27/32 |

2 7/32 |

2 1/2 |

3 1/32 |

3 11/32 |

4 |

4 3/4 |

6 |

|

|

F |

3/4 |

3/4 |

1 |

1 1/8 |

1 1/4 |

1 5/16 |

1 3/8 |

1 11/16 |

1 3/4 |

2 1/16 |

2 1/2 |

3 1/8 |

|

|

Wt |

0.25 |

0.29 |

0.5 |

0.75 |

1.188 |

1.988 |

2.235 |

3 |

4.93 |

7.375 |

13.588 |

19.063 |

|

|

|

|||||||||||||

|

Class 6000 |

|

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

1 1/4 |

1 1/2 |

2 |

2 1/2 |

3 |

4 |

|

B |

1 1/6 |

1 5/16 |

1 9/16 |

1 27/32 |

2 7/32 |

2 1/2 |

3 1/32 |

3 11/32 |

4 |

4 3/4 |

5 3/4 |

– |

|

|

F |

3月4日 |

1 |

1 1/8 |

1 1/4 |

1 5/16 |

1 3/8 |

1 11/16 |

1 3/4 |

2 1/16 |

2 1/2 |

3 1/8 |

– |

|

|

Wt |

0.25 |

0.64 |

0.5 |

1.438 |

2.188 |

2.785 |

4.688 |

5.75 |

9.5 |

15 |

|||

Forged Threaded / Screwed Equal Tee Application

ASME B16.11 Threaded Tee is known to deliver exceptional performance and are generally developed for

meeting the demands. We offer a broad range of Forged Screwed Tee through a worldwide network of stock-keeping branches. This Forged Threaded Tee is use in various industries like :

Stainless Steel Forged Threaded Tee uses in Oil and Gas Pipeline

Forged Threaded Tee uses in Chemical Industry

Alloy Steel Threaded Equal Tee uses in Plumbing

Forged Screwed Equal Tee uses in Heating

Threaded Forged Tee uses in Water Supply Systems

ANSI B16.11 Forged Threaded Tee uses in Power Plant

Threaded Equal Tee uses in Paper & Pulp Industry

Forged Screwed Equal Tee uses in General Purpose Applications

Forged Threaded Tee uses in Fabrication Industry

Forged Screwed Equal Tee uses in Food Processing Industry

Forged Threaded Equal Tee uses in Structural Pipe