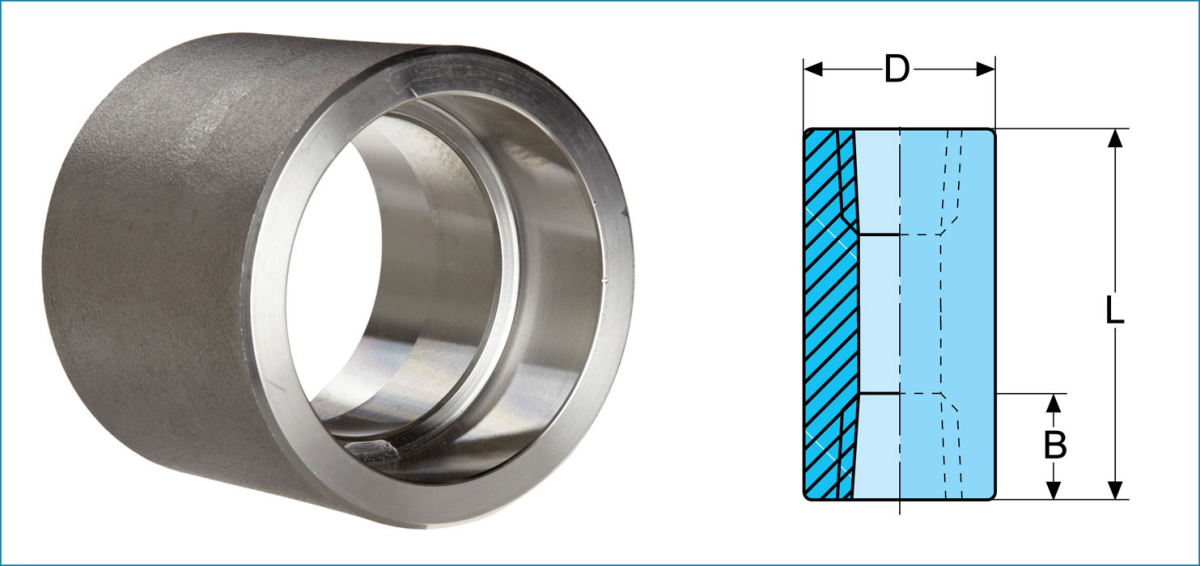

Socket Weld Full Coupling

Bilang isang ISO certified na kumpanya, ang Liaocheng Shenghao Metal products Co., LTD ay nakapasok sa pambansa at internasyonal na mga merkado bilang isa sa mga nangungunang distributor, supplier at stockist ng Socket Weld Full Coupling. Ang Socket Weld Full Couplings ay ginagamit upang ikonekta ang maliit na butaspipe bilang isang projection ng isang welding effect sa pipe bore. Ang magkabilang dulo ng mga Full Coupling na ito ay sinulid. Ang mga ito ay lubos na hinihiling sa merkado ng pipe fitting. Ang mga Stainless Steel Socket Weld Half Coupling na ito ay mahigpit na nasubok upang matiyak ang pinakamataas na kalidad atpagtitiis sa anumang matinding kondisyon. Ang ANSI B16.11 Forged Socket Weld Full Coupling na ito ay ginagamit sa mga aplikasyon tulad ng mga parmasyutiko, paggawa ng barko, atbp. Ang HGFF Group Co., Ltd. ay may utang sa kanilangkliyente ang ASME B16.11 Forged Socket Weld Full Couplings sa makatwirang presyo. Ang mga ito ay ibinibigay sa iba't ibang laki at kapal para sa mga partikular na pangangailangan ng mga customer.

ANSI/ASME B16.11 Socket Weld Full Coupling Standard na Detalye

Socket Weld Full Coupling Sizes

| Mga sukat | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Sukat | 1/8″ NB TO 4″ NB |

| Mga Rating ng Presyon | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Form | Buong Couplings, Pagbawas ng Coupling |

| Mga Marka ng Produksyon | Hindi kinakalawang na Steel, Alloy Steel, Duplex, Nickel Alloys, Mababang temperatura na Bakal, Carbon Steel, Cupro Nickel |

Mga Pamantayan sa Paggawa ng Socket Weld Full Coupling

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Forged Socket Weld Full Coupling Material Grades

Nickel Alloy Forged Socket Weld Full Coupling :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS ALL 80Y2, UNS ALL 80Y UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Stainless Steel Forged Socket Weld Full Coupling:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321, F321, F321, F321H F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex at Super Duplex Steel Forged Socket Weld Full Coupling :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Socket Weld Full Coupling:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld Full Coupling :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 CR2, 1/4 CR, 1 CR2, 1/4 CR 91

Copper Alloy Steel Forged Socket Weld Full Coupling: ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 45/10) , C 71500 ( CU -NI- 70/30)

ASME B16.11 Forged Socket Weld Full Coupling Available Uri

| Forged Socket weld Full Coupling | Socket Weld Full Coupling Class 3000 |

| Socket Weld Reducing Coupling | 3 4 Socket Weld Full Coupling |

| ASME B16.11 Socket Weld Reducing Coupling | 3000LB Socket Weld Full Coupling |

| ANSI B16.11 Forged Socket Weld Full Coupling | Class 6000 Socket Weld Full Coupling |

| Socket Weld Full Coupling Weight | BS 3799 Forged Socket Weld Full Coupling |

| Socket Weld Full Coupling Reducer | High Quality Socket weld Full Coupling |

| 2 Socket Weld Full Coupling | 1/2 Socket Weld Full Coupling |

| 3000# Forged Socket Weld Full Coupling | 3/4 Socket Weld Full Coupling |

| 5 Socket Weld Full Coupling | 1 pulgadang Socket Weld Full Coupling |

| 8 Socket Weld Full Coupling | 2 pulgadang Socket Weld Full Coupling |

| 6000# Socket Weld Full Coupling | 3 pulgadang Socket Weld Full Coupling |

| 6 Socket Weld Full Coupling | 6 pulgadang Socket Weld Full Coupling |

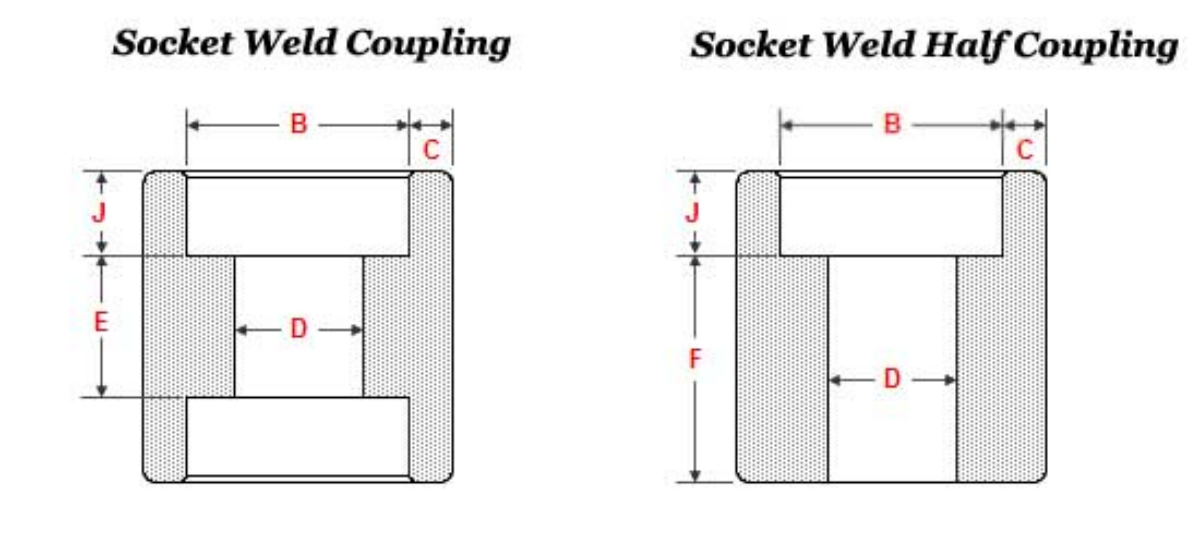

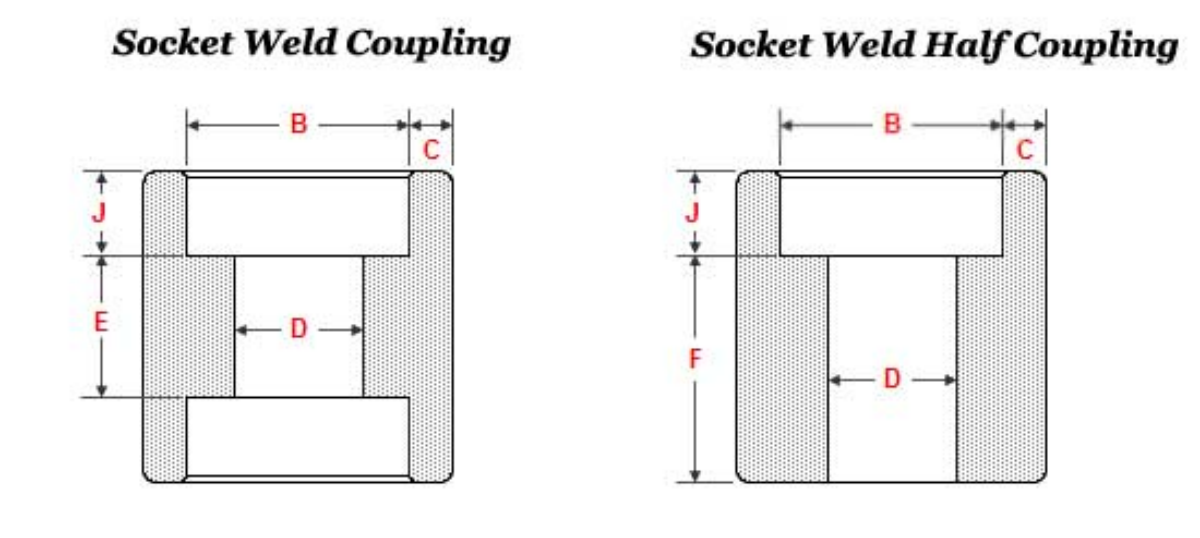

ANSI/ASME B16.11 SOCKET WELD FULL COUPLING DIMENSIONS

Socket Weld Reducing Coupling Dimensions

3000# Socket Weld Coupling Dimensions

| NPS | Socket Bore | Lalim Socket | Bore DIA | Socket pader THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 | 4.65 4.10 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 | 4.90 4.25 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 | 5.70 5.00 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 | 6.05 5.30 |

| 1.1/2 | 48.90 48.65 | 13 | 41.7 40.1 | 6.35 5.55 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 | 6.95 6.05 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 | 8.75 7.65 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 | 9.50 8.30 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 | 10.70 9.35 |

| NPS | Haba ng pagtula | |||

| Pagsasama E | Half coupling F | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 | 47.5 | ||

6000# Socket Weld Coupling Dimensions

| NPS | Socket | Lalim | Bore | Socket |

| B | J | D | C | |

| 1/2 | 21.95 | 10 | 12.5 | 5.95 |

| 3/4 | 27.30 | 13 | 16.3 | 6.95 |

| 1 | 34.05 | 13 | 21.5 | 7.90 |

| 1.1/4 | 42.80 | 13 | 30.2 | 7.90 |

| 1.1/2 | 48.90 | 13 | 34.7 | 8.90 |

| 2 | 61.35 | 16 | 43.6 | 10.90 |

| NPS | Haba ng pagtula | |||

| Pagsasama | Half coupling | |||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

Ang mga sukat ay nasa millimeters maliban kung iba ang ipinahiwatig.

Socket Bore (B) – Pinakamataas at pinakamababang sukat.

Bore Diameter (D) – Pinakamataas at pinakamababang sukat.

Kapal ng pader ng socket – (C) – Katamtaman ng kapal ng pader ng Socket.

Ang mga dimensional tolerance center sa ilalim ng socket - (A)

NPS 1/2 at NPS 3/4 = +/- 1.5 mm

NPS 1 hanggang NPS 2 = +/- 2 mm

NPS 2.1/2 hanggang NPS 4 = +/- 2.5 mm