Ukuhlolwa kwe-Flange dimension: ilitye lembombo lobugcisa bomlinganiselo ochanekileyo kunye nokhuseleko lwamashishini

Kwinkqubo entsonkothileyo yemibhobho yoshishino, iiflange, ezibonakala zingabalulekanga zokudibanisa amacandelo, zidlala indima ebalulekileyo. Zifana namalungu emithanjeni yegazi, eqinisekisa ukuhamba kakuhle kolwelo kwimibhobho kunye nokusebenza kwenkqubo ezinzileyo. Phakathi kwabo, ukuhlolwa okuchanekileyo kwemilinganiselo ye-flange kuye kwaba likhonkco eliphambili ekuqinisekiseni ukhuseleko lwamashishini kunye nokuphucula ukusebenza kakuhle kwemveliso.

Ukuhlolwa komgangatho we-Flange, njengoko igama libonisa, kukulinganisa okucokisekileyo kunye nokuqinisekiswa kweeparamitha ezinobungakanani beeflange. Ukusuka kwidayamitha engaphandle ukuya kwidayamitha engaphakathi, ukusuka kubukhulu ukuya kwidayamitha yomngxuma webholiti, yonke idatha kufuneka ilinganiswe ngokungqongqo kwaye ithelekiswe ukuqinisekisa ukubambelela kwayo ngononophelo kwimizobo yoyilo kunye nemigangatho yoshishino. Oku akukona nje umsebenzi wobugcisa, kodwa kunye nobugcisa obulandela ukuchaneka.

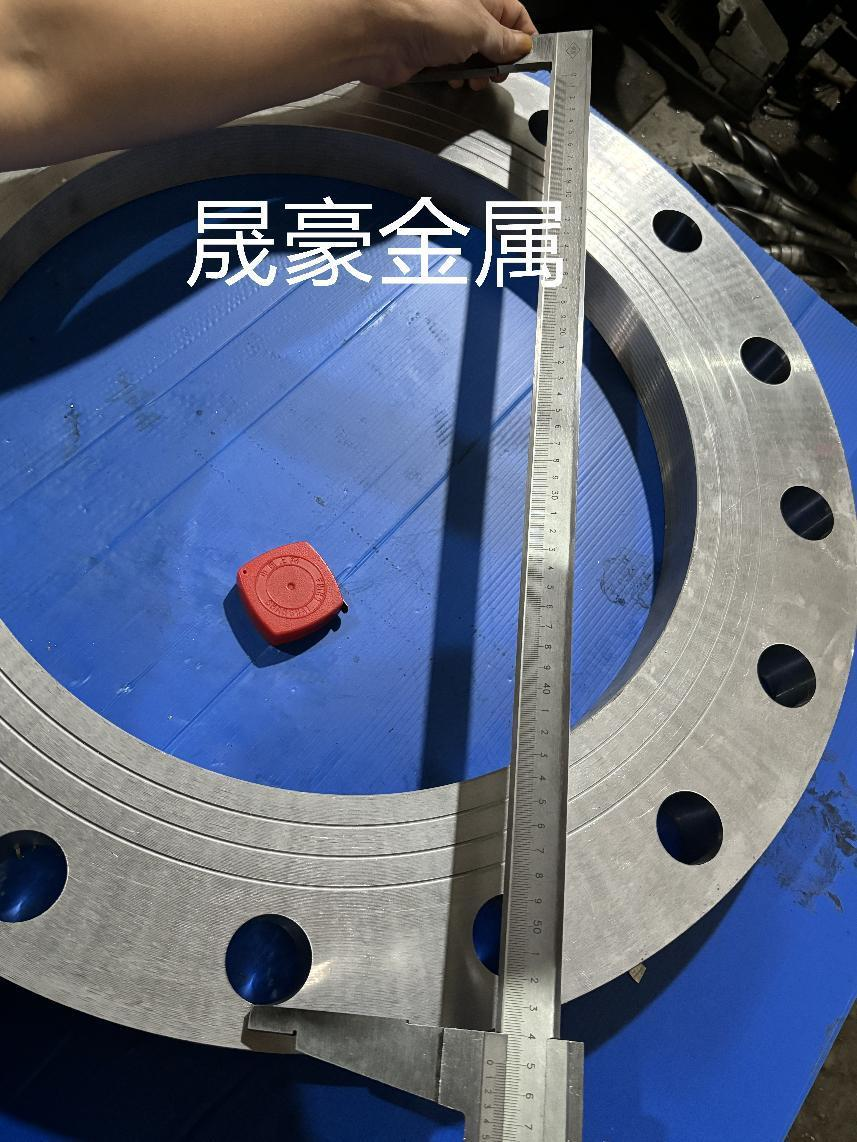

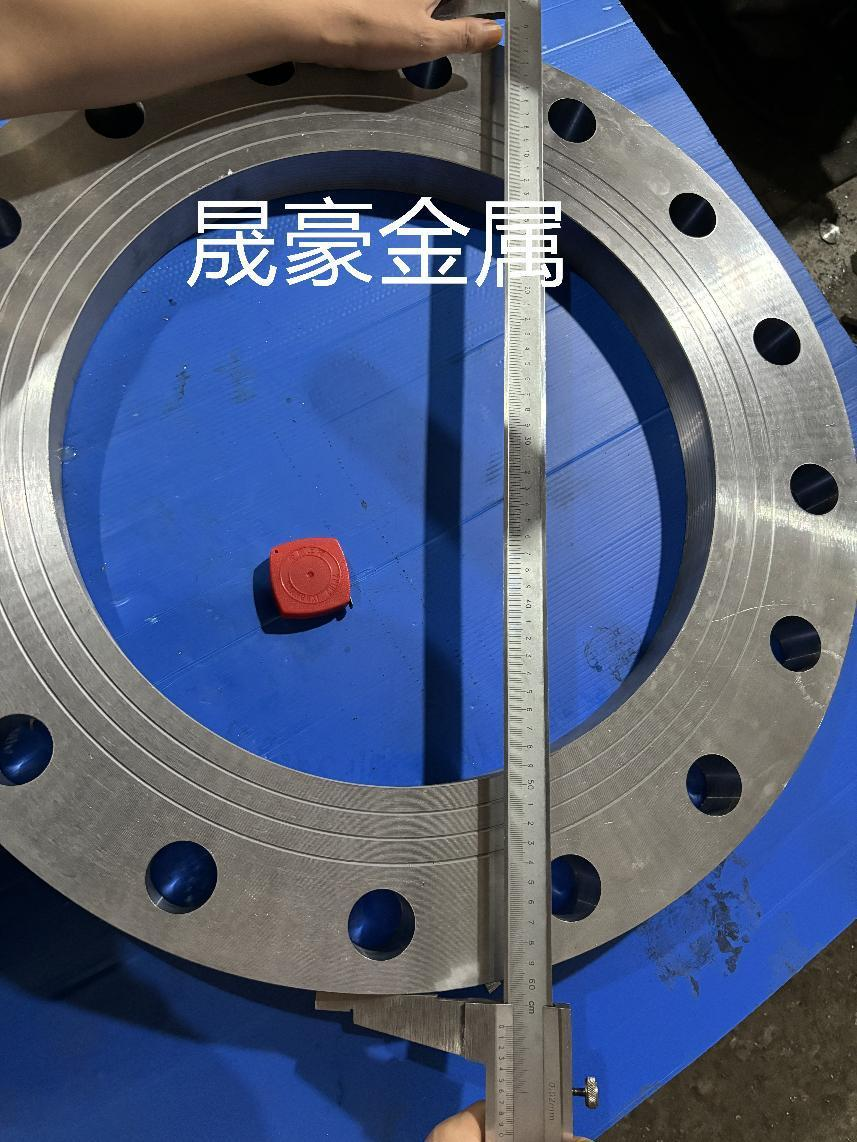

Ukukhethwa kunye nokusetyenziswa kwezixhobo zokulinganisa kubalulekile kwinkqubo yokuhlolwa kobungakanani beflange. Izixhobo ezichanekileyo ezifana ne-vernier calipers, i-micrometers, kunye neegeji ze-diameter yangaphakathi, njengeemela zokukrola ezandleni zamagcisa, zifuna izandla ezinobuchule zabahloli ukuze zibonise ngokuchanekileyo imilinganiselo yokwenyani yeeflange. Kwaye yonke imilinganiselo iluvavanyo lomonde kunye nobuchule babahloli. Nakuphi na ukungakhathali kunokuba neempembelelo ezingenakulinganiswa ekufakeni nasekusebenziseni okulandelayo.

Ukuhlolwa okuchanekileyo kwemilinganiselo yeflange kubaluleke kakhulu kukhuseleko lwamashishini. Ubungakanani obukhulu kakhulu okanye obuncinci kakhulu bunokukhokelela kuqhagamshelo phakathi kweeflange kunye nemibhobho, okukhokelela kwiziphumo ezimandundu ezinje ngokuvuza, ukungcangcazela, kunye nokudubula. Ngoko ke, iflenge nganye kufuneka ihlolwe ngokungqongqo phambi kokuba iwushiye umzi-mveliso ukuqinisekisa ukuba inokuhlanganiswa ngokugqibeleleyo kwinkqubo yemibhobho kwaye ikhusele ukusebenza ngokukhuselekileyo koshishino.

Ukongeza, ukuhlolwa kobungakanani beflange kukwasisiqinisekiso esibalulekileyo sokuphucula ukusebenza kakuhle kwemveliso. Ukulinganisa ubungakanani obuchanekileyo kunokunciphisa kakhulu ukulungiswa kunye nexesha lokulungisa ngexesha lofakelo, kunye nokuphucula ukusebenza kakuhle. Kwangaxeshanye, kukwanceda ekunciphiseni ukusebenza ngokutsha kunye ne-scrap ebangelwa kukungangqinelani kobungakanani, iindleko eziphantsi zemveliso, kunye nokufaka ubutsha obutsha kuphuhliso oluzinzileyo lwamashishini.

Isishwankathelo, ukuhlolwa kobukhulu be-flange akuwona nje umsebenzi wezobugcisa, kodwa kunye nomsebenzi obalulekileyo onxulumene nokhuseleko lwamashishini kunye nokusebenza kakuhle kwemveliso. Ifuna ukuba abahloli babe noluvo oluphezulu loxanduva kunye nobuchule obuchwephesha, ukulinganisa ngokuchanekileyo kunye nokulawula ngokungqongqo ubungakanani beflange nganye, kwaye bafake isandla kwiinzame zabo ekusebenzeni ngokukhuselekileyo nokusebenzayo kolu shishino. Kuphuhliso lweshishini lwexesha elizayo, sijonge phambili ekusungulweni okuqhubekayo kunye nenkqubela phambili ekuhloleni ubungakanani beflange, ukubonelela ngesiqinisekiso esiqinileyo sokhuseleko kunye nokuzinza kweenkqubo zemibhobho yeshishini.

Ixesha lokuposa: Sep-23-2024