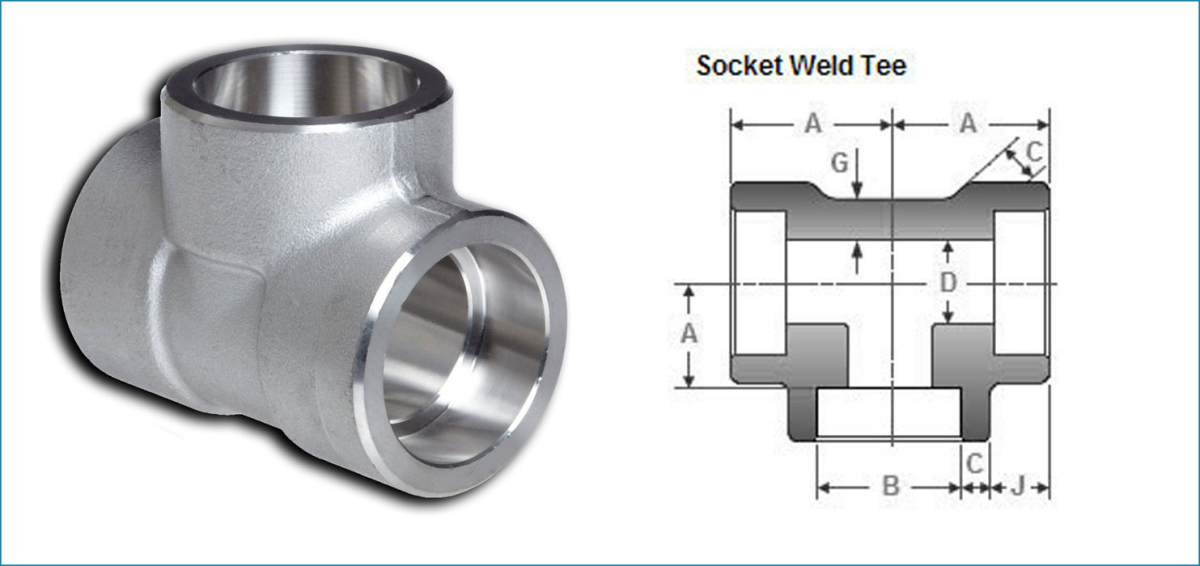

I-Socket Weld Tee

I-Liaocheng Shenghao Metal products Co., LTD ngumenzi ogunyazisiweyo, umboneleli kunye nomthumeli ngaphandle kwe-ASME B16.11 Socket Weld Tee, eyenziwe ngokwemilinganiselo yemigangatho yehlabathi. I-Socket Weld Tee Fittings yethu iza kwiiklasi ezahlukeneyo kunye namabakala ezinto eziphathekayo kwizicelo ezahlukeneyo zemizi-mveliso. I-Forged Socket Weld Equal Tee yethu yenza isebe le-90 ° ukusuka kwindawo ehamba phambili yombhobho.

Sinikezela ngezi Socket Weld Tees kwizicelo ezahlukeneyo zemizi-mveliso njengokusetyenzwa kweekhemikhali, iindawo zokucokisa ioyile, i-petrochemical kunye namanye amashishini amaninzi. I-ANSI B16.11 ye-Forged Socket Weld Tee ibubungqina bokuvuza kwaye iyamelana nokuhlwa. I-Socket Weld Equal Tees isetyenziselwa imigca eyityhefu ehambisa izinto ezinokutsha okanye ezixabisa kakhulu apho kungavunyelwa ukuvuza, kunye ne-steam 300 ukuya kwi-600 PSI.

I-ANSI/ASME B16.11 Inkcazo yoMgangatho weSocket Weld Tee

| Imilinganiselo | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Ubungakanani | 1/2″NB UKUYA 4″QAPHELA |

| Iklasi | 3000 LBS, 6000 LBS, 9000 LBS |

| Uhlobo | I-Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Ifom | I-Sockte Weld Tee, i-Socket Weld Equal Tee |

| AmaBanga oMveliso | Intsimbi engatyiwayo, intsimbi yentsimbi, iDuplex, iNickel Alloys, intsimbi yobushushu obuphantsi, iCarbon Steel, Cupro Nickel |

ImiGangatho yokuVelisa ye-Socket Weld Equal Tee

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| I-DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

AmaBanga oMathiriyeli we-Socket weld weld Tee

I-Nickel Alloy Forged Socket Weld Tee :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 30 CB / YLO 20 UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

iTee yeWeld yeStainless Steel Forged Socket :

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F31, F31, F31, F71 F347H, F904L, ASTM A312/A182 TP304, TP304L, TP316, TP316L

I-Duplex & Super Duplex Steel Forged Socket Weld Tee :

I-ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

I-Carbon Steel Forged Socket Weld Tee :

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

I-alloy Steel Forged Socket Weld Tee :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, CR, CR, CR 91

I-Copper Alloy Steel Forged Socket Weld Tee : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

ASME B16.11 Forged Socket Weld Tee Iintlobo ezifumanekayo

| Forged Socket weld Tee | I-Socket Welding yokunciphisa iTee |

| I-150 lb. I-Socket Weld Fittings yePipe Tee | 2 intshi Socket weld Tee |

| ASME B16.11 Socket weld Equal Tee | 3000LB Socket Weld Tee |

| Izixhobo ze-Socket Weld Tee | iklasi 6000 Socket Weld Forged Tee |

| ANSI B16.11 Forged Socket Weld Tee | BS 3799 Forged Socket Weld Tee |

| I-Socket eyakhiweyo weld Equal Tee | Socket Weld Equal Tee Weight |

| Socket weld Tee Reducer | Umgangatho ophezulu weSocket weld Tee |

| 1 intshi yeSocket Weld Tee | I-Socket Weld Pipe Tee |

ASME B16.11 Forged Socket Weld 90 Deg Elbow Iintlobo ezifumanekayo

| Forged Socket weld Elbow 90 Degree | Forged Socket weld Long Radius 90 Degree Elbows |

| I-150 lb. I-Socket Weld Fittings Umbhobho we-Elbow | I-Socket weld 90° i-Radius Emfutshane i-Elbow |

| ASME B16.11 90 deg Socket weld Elbow | 90 Degree Elbow 3000LB Socket Weld |

| I-Socket Weld Fittings 90 Degree Pipe Elbow | Umgama omde weSocket Weld 90 Deg. Iingqiniba Zokwenziwa |

| ANSI B16.11 90 Degree Forged Elbow | BS 3799 Forged 90 Degree Elbow |

| Forged Socket weld 90 Deg Elbow | Socket weld 90° Umbhobho we Elbow |

| I-Socket weld 90deg. Ingqiniba | Umgangatho ophezulu weSocket weld 90° Elbow |

| 90° Socket Weld Elbow | I-Socket Weld 90 ingqiniba |

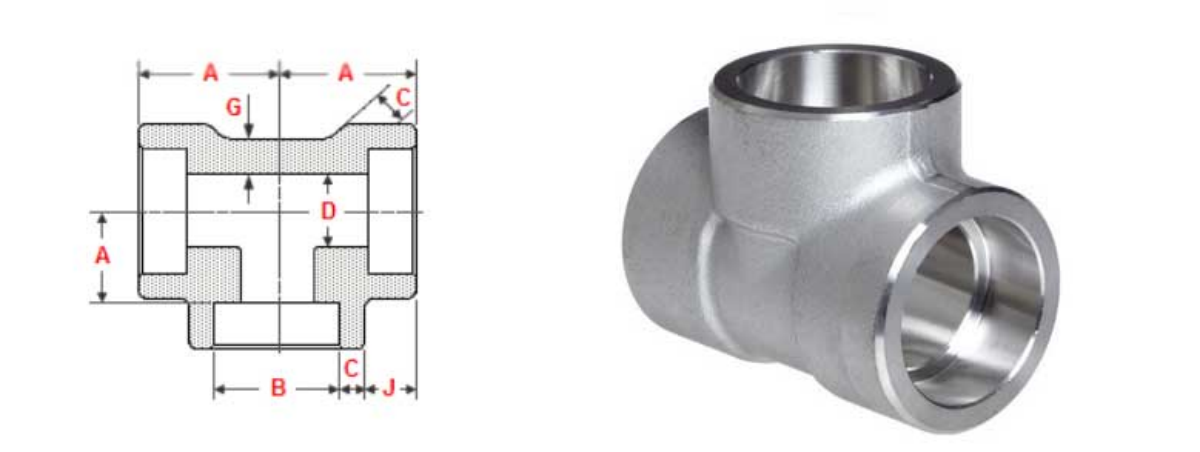

ANSI/ASME B16.11 SOCKET WELD TEE DIMENSIONS

Socket Weld Equal Tee Dimensions

Udidi lwe-3000 ye-Socket Weld Tee Imilinganiselo ye-NPS 1/2 ukuya ku-2

| NPS | I-Socket Bore | Isiseko sobunzulu | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 | 10 | 16.6 15 |

| 3/4 | 27.30 27.05 | 13 | 21.7 20.2 |

| 1 | 34.05 33.80 | 13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 | 13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 | 13 | 41.7 40.1 |

| 2 | 61.35 61.10 | 16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 | 16 | 64.2 61.2 |

| 3 | 90.15 89.80 | 16 | 79.5 46.4 |

| 4 | 115.80 115.45 | 19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 | 3.75 | 15.5 |

| 3/4 | 4.90 4.25 | 3.90 | 19.5 |

| 1 | 5.70 5.00 | 4.55 | 22 |

| 1.1/4 | 6.05 5.30 | 4.85 | 27 |

| 1.1/2 | 6.35 5.55 | 5.10 | 32 |

| 2 | 6.95 6.05 | 5.55 | 38 |

| 2.1/2 | 8.75 7.65 | 7.00 | 41.5 |

| 3 | 9.50 8.30 | 7.60 | 57.5 |

| 4 | 10.70 9.35 | 8.55 | 66.5 |

I-Class 6000 Socket Weld Tee Dimensions NPS 1/2 ukuya ku-2

| NPS | I-Socket Bore | Isiseko sobunzulu | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 | 10 | 12.5 11 |

| 3/4 | 27.30 27.05 | 13 | 16.3 14.8 |

| 1 | 34.05 33.80 | 13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 | 13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 | 13 | 34.7 33.2 |

| 2 | 61.35 61.10 | 16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 | 4.80 | 19.5 |

| 3/4 | 6.95 6.05 | 5.55 | 22.5 |

| 1 | 7.90 6.95 | 6.35 | 27 |

| 1.1/4 | 7.90 6.95 | 6.35 | 32 |

| 1.1/2 | 8.90 7.80 | 7.15 | 38 |

| 2 | 10.90 9.50 | 8.75 | 41 |

Imilinganiselo ikwimillimeters ngaphandle kokuba kuboniswe ngenye indlela.

I-Socket Bore (B) - Ubuninzi kunye nemilinganiselo encinci.

I-Bore Diameter (D) - Ubuninzi kunye nemilinganiselo encinci.

Ubunzima bodonga lwesokethi - (C) - Umyinge wobunzima bodonga lweSocket.

Iziko lokunyamezelwa komgangatho ukuya ezantsi kwesokethi - (A)

I-NPS 1/2 kunye ne-NPS 3/4 = +/- 1.5 mm

I-NPS 1 ukuya kwi-NPS 2 = +/- 2 mm

I-NPS 2.1/2 ukuya kwi-NPS 4 = +/- 2.5 mm

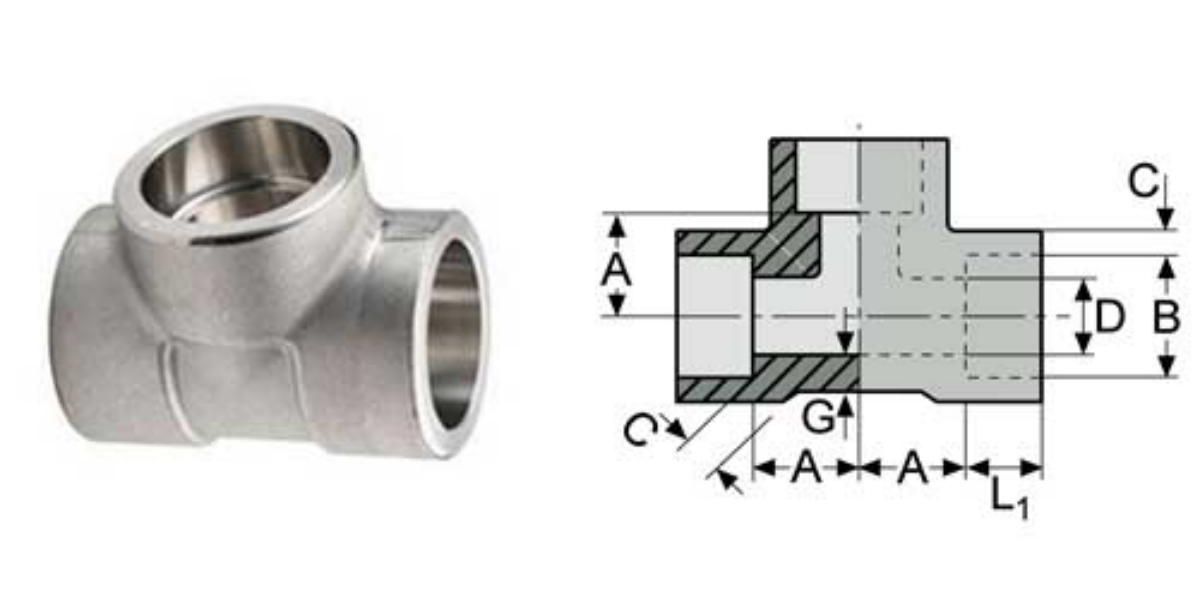

Socket weld Equal Tee Weight

| Ubungakanani bombhobho oqhelekileyo | B | L1 | C | G | D | A | Ubunzima |

| kwi. | mm | isiseko | mm | mm | mm | mm | ~kg/pce |

| 1/4 | 14.20 | 9.53 | 3.30 | 3.02 | 8.86 | 11.11 | 0.11 |

| 1 | 33.90 | 12.50 | 4.98 | 4.55 | 26.26 | 22.23 | 0.65 |

Forged Socket Tee Isicelo

ASME B16.11 45 iDegree Socket weld Tee yaziwa ngokunika umsebenzi obalaseleyo kwaye ngokubanzi

iphuhliselwe ukuhlangabezana neemfuno. Sityala uluhlu olubanzi lweForged 45 Degree Socket weld Tee ngokusebenzisa a

uthungelwano lwehlabathi lonke lwamasebe okugcina izabelo. Le 45Deg. I-Socket weld Tee isetyenziswa kumashishini ahlukeneyo afana nala:

Isinyithi esingenaStainless 45° kusetyenziswa iTee eQithiweyo kuMbhobho we-Oli neGesi

I-45 ° isetyenziselwa iPipe Tee kwi-Chemical Industry

I-alloy Steel 45° Tee isetyenziswa kwiiPlumbing

Forged 45 Degree Pipe Tee usebenzisa Ukufudumeza

45 iDegree Forged Tee isebenzisa kwiiNkqubo zoBonelelo lwaManzi

ANSI B16.9 Forged 45° Pipe Tee isetyenziswa kwi-Power Plant

45° Ukusetyenziswa kweTee kuShishino lwePhepha kunye nePulp

I-45° iDegree Tee isetyenziswa kwiZicelo zeNjongo ngokuBanzi

Yakhiwe ngama-45° ende yeRadius Tee esetyenziswa kuShishino lokuFakwa

I-45° isetyenziselwa iTee yeForged kuShishino lokuLungisa ukutya

Forged 45° Short Radius Tee isebenzisa kuMbhobho woLwakhiwo